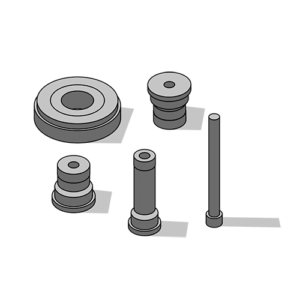

We are an International Contract Manufacturer of sintered metal components producing gears, planetary gear carriers, couplings, rotors and ratchets for unique applications.

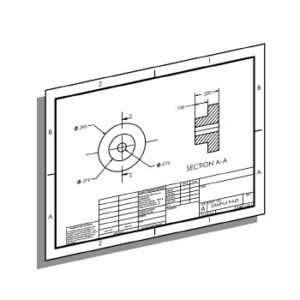

Engineering & Design

- Collaborative Design

- Solid Modelling

- Simulation

- Prototype 3D Printing

Tooling & Compacting

- 4 to 220 Tons Pressing Capacity

- Fluidized Die Cavity Filling

- Real time Press Force Monitoring

- Multi-Cavity Tool Designs

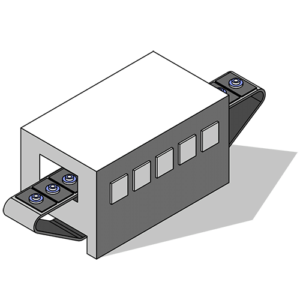

Sintering & Thermal Processing

- Continuous Belt Furnaces

- High Temperature Pusher Furnace

- Temper & Annealing Furnaces

- Coining, Plating, Machining

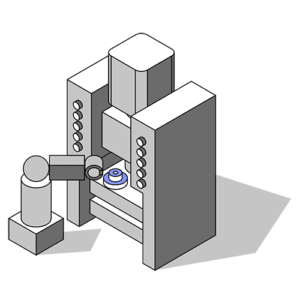

Automation

& Testing

- No human contact with Compacted parts

- 3-Axis Pick &Place

- 5-Axis FANUC Robots

- Conveyor loaded Sintering Furnaces

Quality Control

- Non-Destructive Resonant Testing

- Destructive Torque & Tensile testing

- On-site Metallurgical Laboratory

- Qualified Metallurgical Analysis

Since 1946, ASCO has created cutting-edge powdered metal

design solutions and offered high-quality engineering services and support.