What is Powder Metallurgy (PM)?

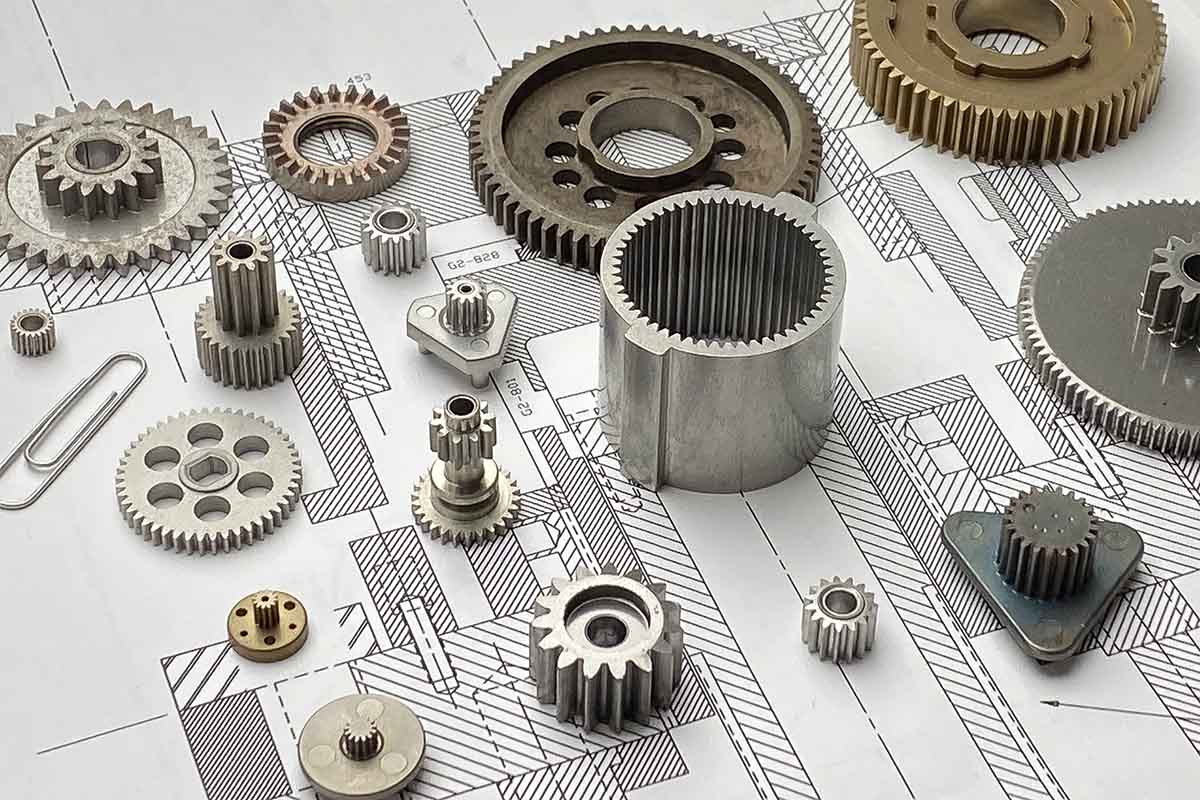

WHAT IS PM? Powder metallurgy-or PM-is a state -of-the-art metal-forming process used

When to use Powder Metallurgy (PM)?

WHEN TO USE PM When to use PM is a commonly asked

Advantages of Powder Metallurgy (PM)

ADVANTAGES OF POWDERED METALLURGY Powder metallurgy is a well- established mass production method

Conventional Powder Metallurgy (PM) Process

CONVENTIONAL PM PROCESS Also known as press-and-sinter, the process consists of mixing elemental

- over 3,000 pm sintered metal design solutions implemented during its 70 year history

- an industry record number of metal powder industries federation design for excellence awards

- cost savings estimated at over $1mm when compared to traditional machining methods

- high volume automotive gears to low volume specialty sinter bonded assemblies

- proprietary high strength steels, brass, bronze, copper, soft magnetic alloys and stainless steels

- collaborative design approach to cost reducing powder metallurgy product solutions

- servicing automotive, fluid power, lock hardware, leisure & garden, industrial motors, munitions markets