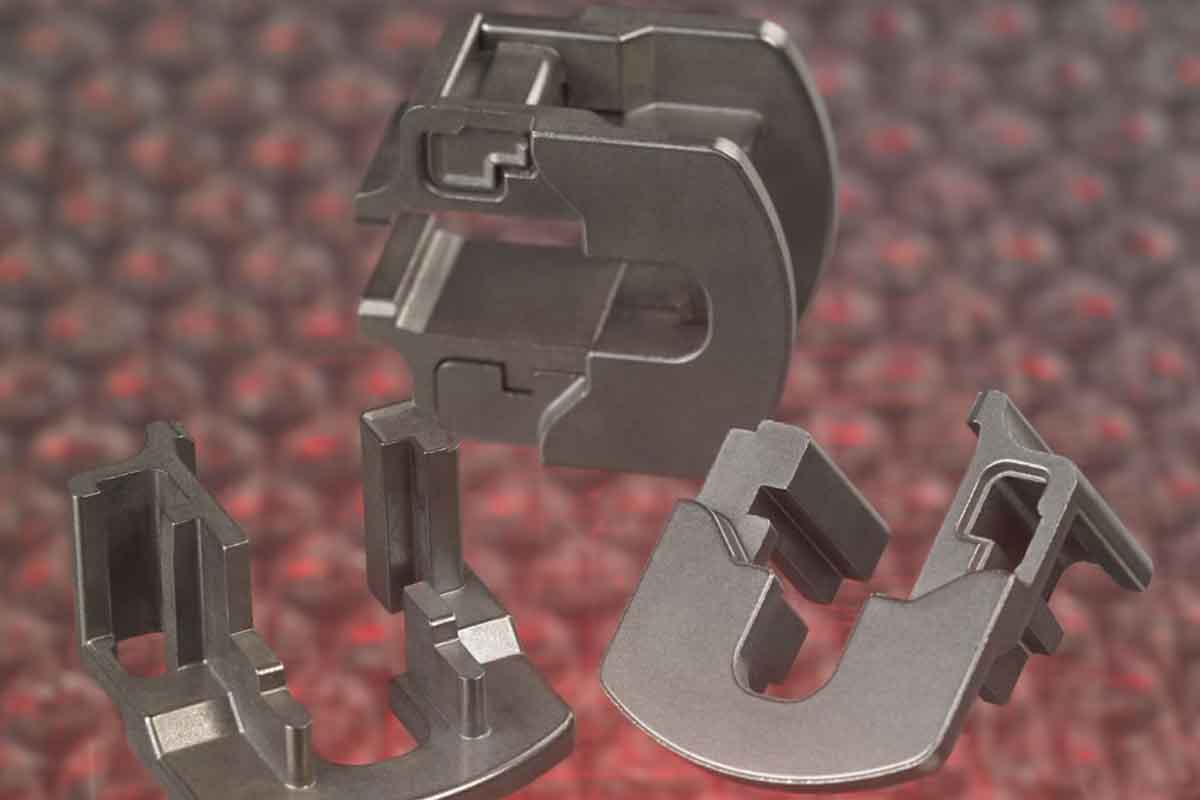

- Complex, multi-level tool design

- Copper Infiltrated PM Steel

- Net-shape eliminates costly slot machining

- Sole secondary operation is a drilled hole

A PM copper–steel outer hub exit spindle used in electronic door locks won the grand prize in the hardware/appliances category. The part connects a standard lock and an exit device. When activated through a code or electronic card reader, the spindle rotates to the standard lock assembly. The powder metallurgy (PM) spindle is made to a 7.7 g/cm3 density and has a 95,000 psi ultimate tensile strength, 8 percent elongation, and 90 HRB hardness. The PM process allowed 95% materials utilization as opposed to machining a wrought blank which yields a materials utilization figure of only 45%. PM also provided a 90% energy savings.