Medical devices

Maximum Cost Savings Tight tolerance capability Six Sigma and lean manufacturing methodologies

Gear adjuster

Two piece sinter-bonded designCombining 70/30 & 80/20 BrassComplex spur gear configurationRadial flange teeth & blind

Sprinkler drive gears

Miniature AGMA 8 Spur gears 0.001" tolerance on the ID High temperature 316 stainless

Snow blower idler pulley

Net-shape vertical spline geometryOpposite blind counter boresLimit secondary operation costs to machining pulley form onlyASCO

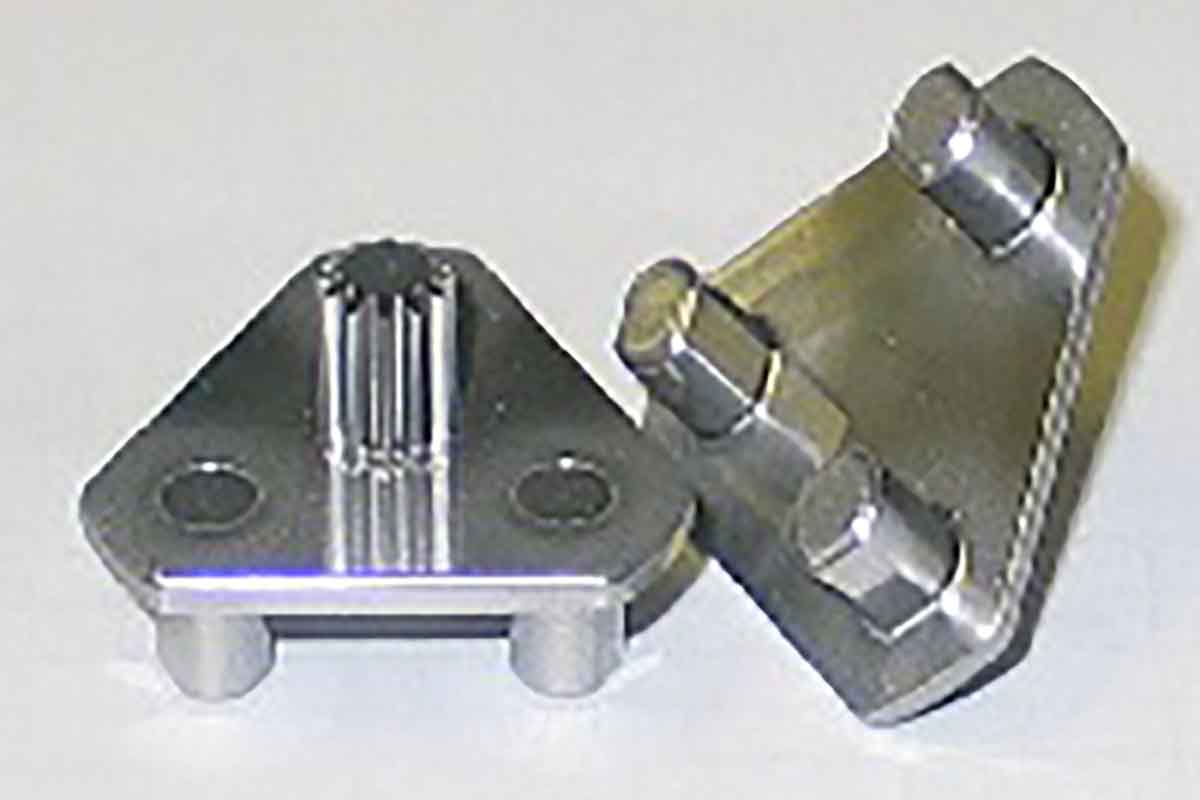

Sprinkler radius adjust head

Miniature high density 316 stainless steelProvides excellent corrosion resistanceHex drive adjustment opposite protrusionsProvide net shape

Lawn & Garden

Maximum Cost Savings Tight tolerance capability Six Sigma and lean manufacturing methodologies

Spur gears

AGMA 8 level METRIC Gears Sinter hardened nickel steel minimizes processing steps Multi-cavity tool

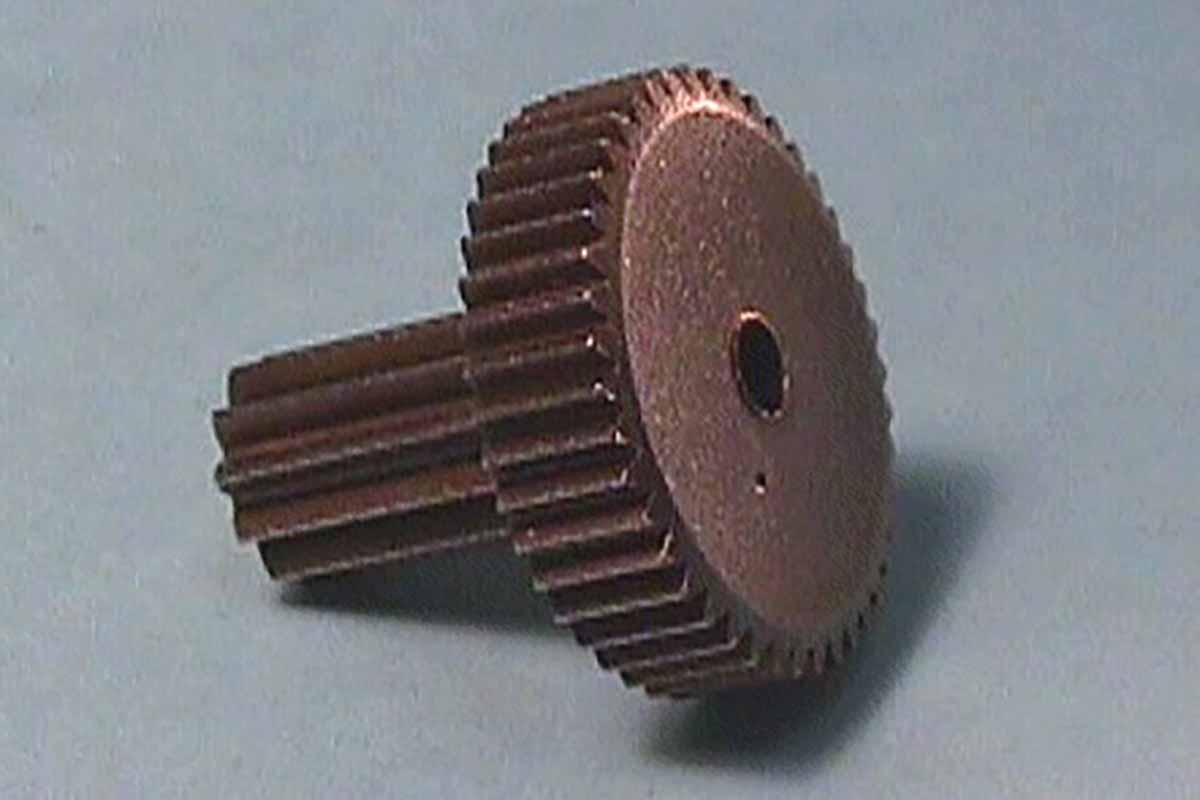

Double gears

AGMA 8 Flange & Pinion gear combination Sinter Hardened Nickel steel alloy High strength

Gear carriers with integral posts

Actuator motor applications for many industries Sinter Hardened Nickel steel Net shape tool design

Bevel gears

Provides 90 degree actuator motor directional drive changeHeat treated Copper Infiltrated PM steelNet shape bevel

Industrial Motors & Gears

Maximum Cost Savings Tight tolerance capability Six Sigma and lean manufacturing methodologies

Compound gears

Fuel control system componentsHeat treated sintered nickel steelNet-shape flange and pinion gear combination100% NDT Qualification