Spring seats

Fluid control system componentsHigh temperature 316 stainless steelHigh ductility and excellent corrosion resistanceTight toleranced secondary

Valve holders

Hydraulic or pneumatic quick disconnect systemsSuperior strength, wear resistance and impact propertiesSpecialized plating provides extreme

Valve guides

Hydraulic or pneumatic quick disconnect systems Sintered brass or stainless steel Complex geometries achieved

Fluid power

Maximum Cost SavingsTight tolerance capabilitySix Sigma and lean manufacturing methodologiesCollaborative creative tooling designHigh

Safety weights

Safety weight, part of a shim assembly Fully dense sintered brass High ductility permits

Missile test brake shoe

Missile defense testing component Net-shape heat treated nickel steel Exceptional strength, wear resistance and

40 mm fuse rotors

High & Low Velocity or Self Destruct sintered brass Fuse Rotor Net-shape extremely tight

Defense ordnance fusing

Maximum Cost SavingsTight tolerance capabilitySix Sigma and lean manufacturing methodologiesCollaborative creative tooling designHigh

Ejector handles

Rack mount computer equipment ejector handleHigh density sinter hardened steelNet shape complex geometry provides cost

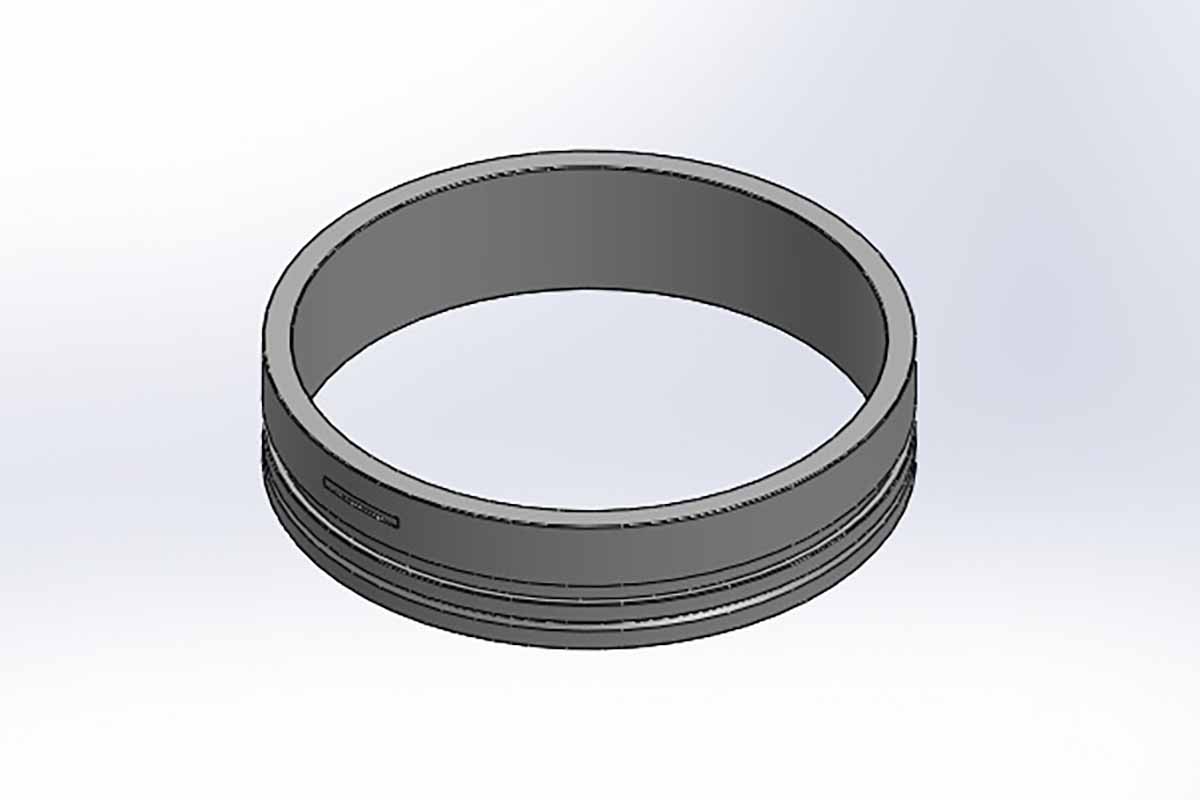

Bearing sleeves

Copier paper feeding mechanism 304 sintered stainless steel Thin cross-sectional areas Tight tolerance secondary

Drive hub

Copier drive hubSintered aluminumPress, sinter & size for increased mechanical propertiesTight geometric tolerances

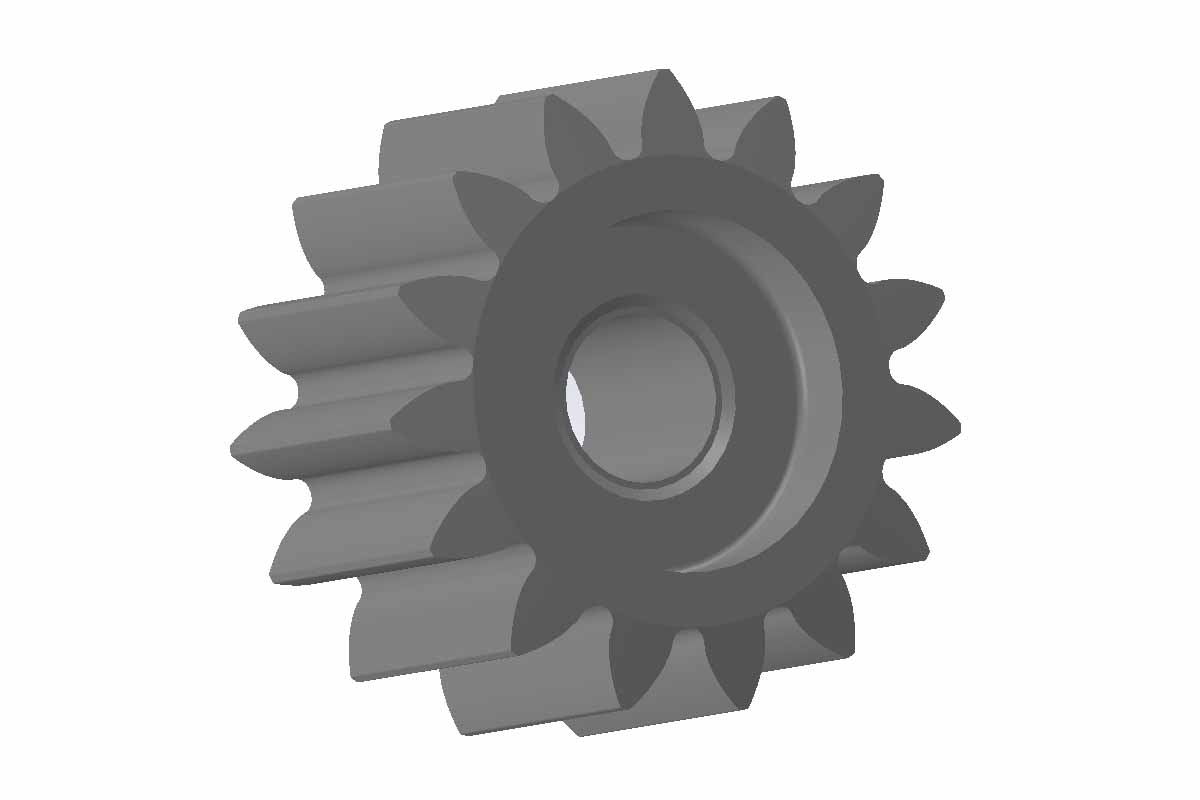

Pinion gears

Display screen adjustment mechanism Heat treated sintered nickel steel Achieving CpK > 1.33 on