Business systems

Maximum Cost Savings Tight tolerance capability Six Sigma and lean manufacturing methodologies

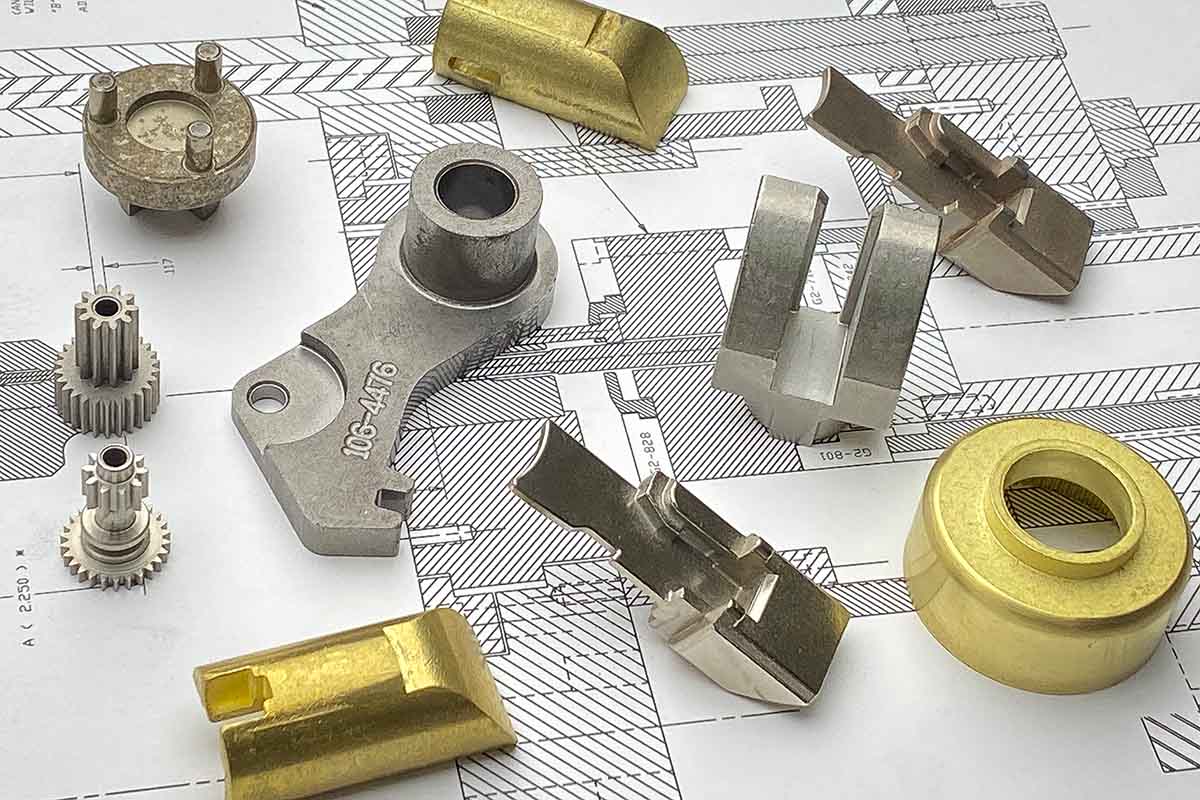

Minivan door clutch assembly

Rotor & Armature with posts and fine pitch matching tooth geometry Soft Magnetic Phosphorous

Four wheel drive shifting

Output Carrier with molded posts and internal ANSI involute splinePropietary HI-IMPAC Ccopper-Infiltrated Sintered Steel16 AGMA

Shift by wire – SBW – sintered components

Compound AGMA 8 gearsTrigger Arms and LinksSinter-Hardened Nickel Steel316 Stainless Steel Couplings100% Non-Destructive TestedASCO Sintering

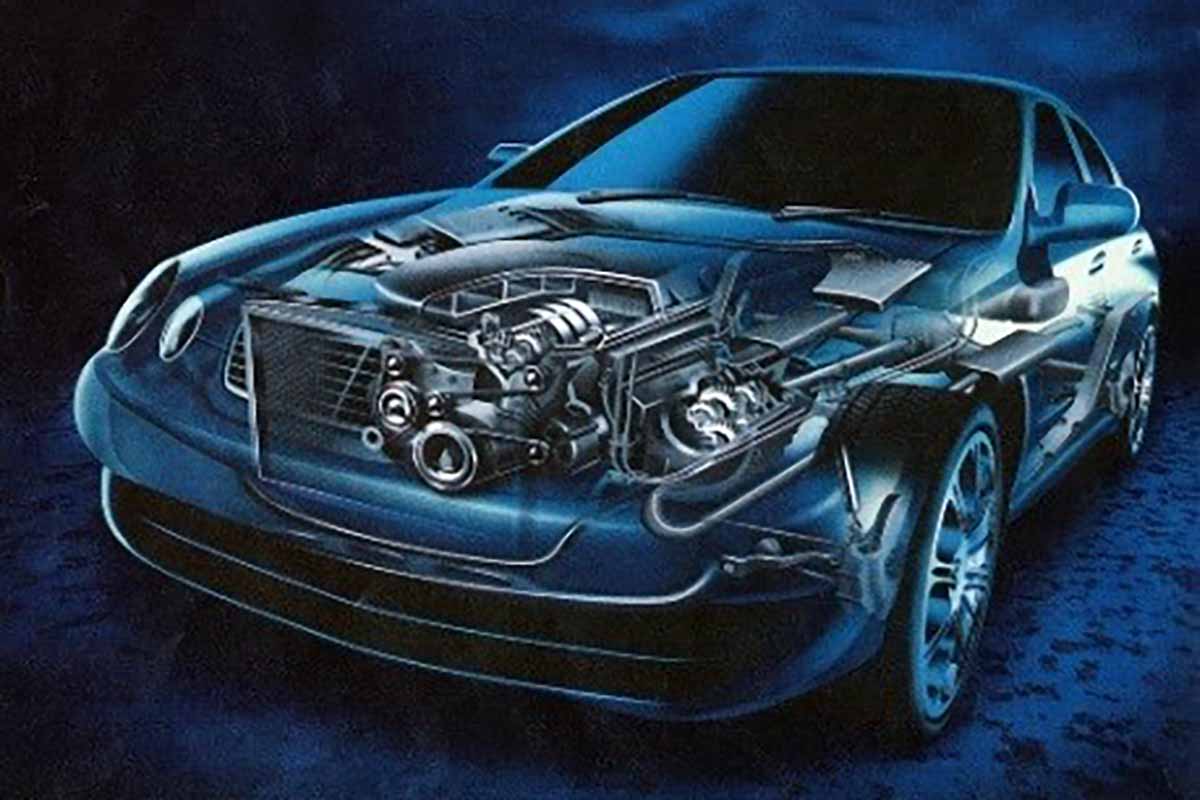

Automotive

Over 10,000,000 PM Sintered Metal parts for the Automotive Industry every year

Brake system balancing weight

High Temperature 316 Stainless SteelSized for enhanced material propertiesExtremely tight geometric tolerancesMultiple versions from a

Rivet crimps

Miniature 0.010" wall thickness MONEL specialty material Optimized processing permits "crimping" without cracking Multi-cavity

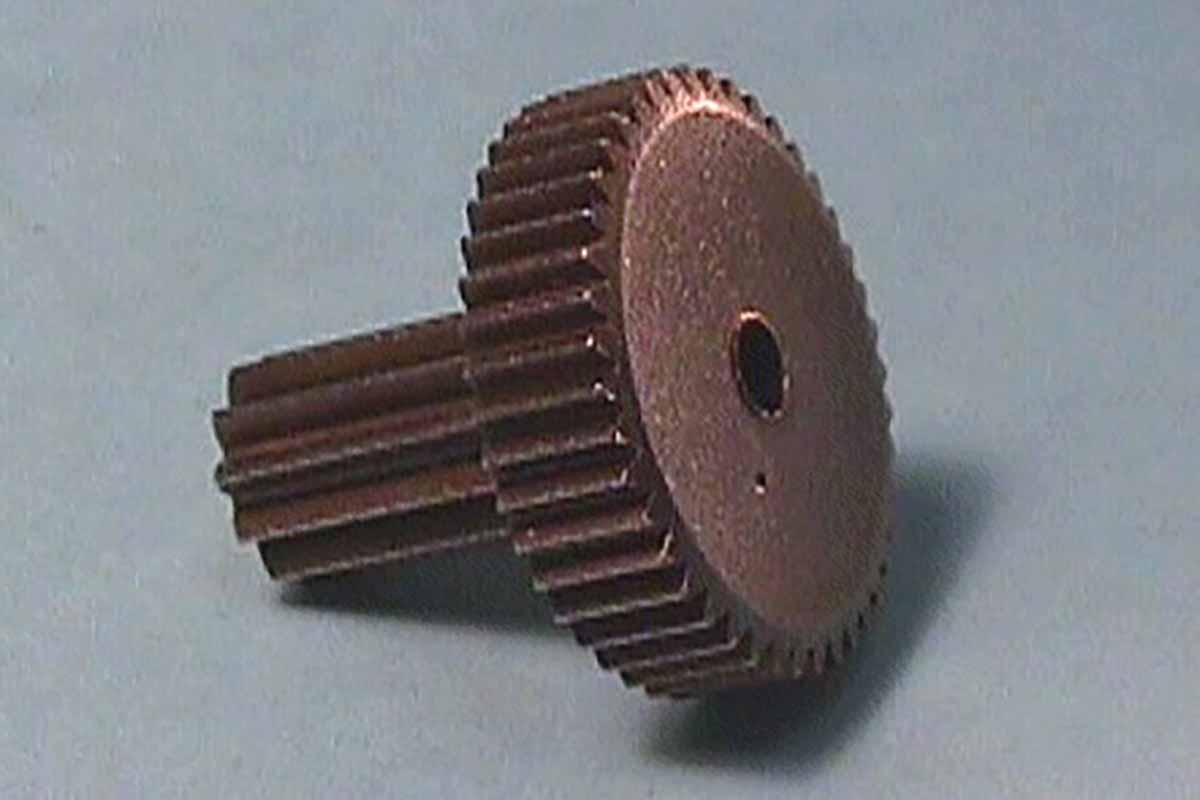

Fuel pump gears

AGMA 8 Compound Gear Heat treated nickel steel for wear and strength Simultaneous manufacture

Splice terminals

Tight tolerance key-hole geometryHigh density pure copper 85-90% IACSExcellent thermal and electrical conductivityDuctility permits "crimping"

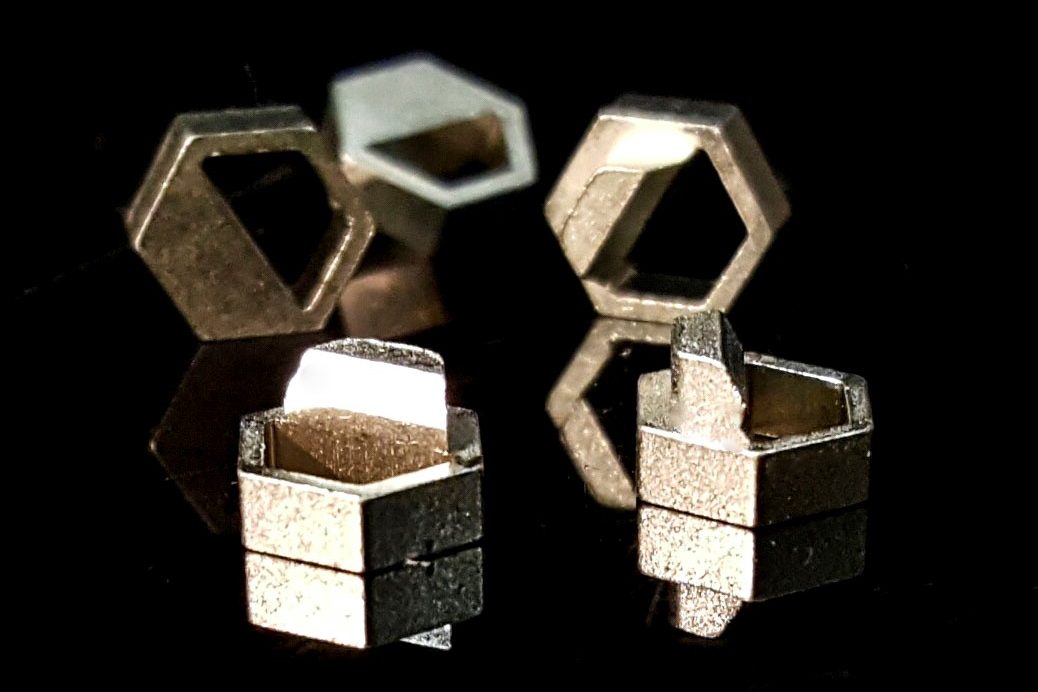

Flight recorder polarizing keys

Net shape thin-walled complex geometryWear resistant nickel silver, polished for appearanceHigh corrosion resistance and tensile

Aerospace

Maximum Cost SavingsTight tolerance capabilitySix Sigma and lean manufacturing methodologiesCollaborative creative tooling designHigh

Metal Powder Molding

In today’s world, manufacturers are always searching for better-performing metal components. They want more freedom