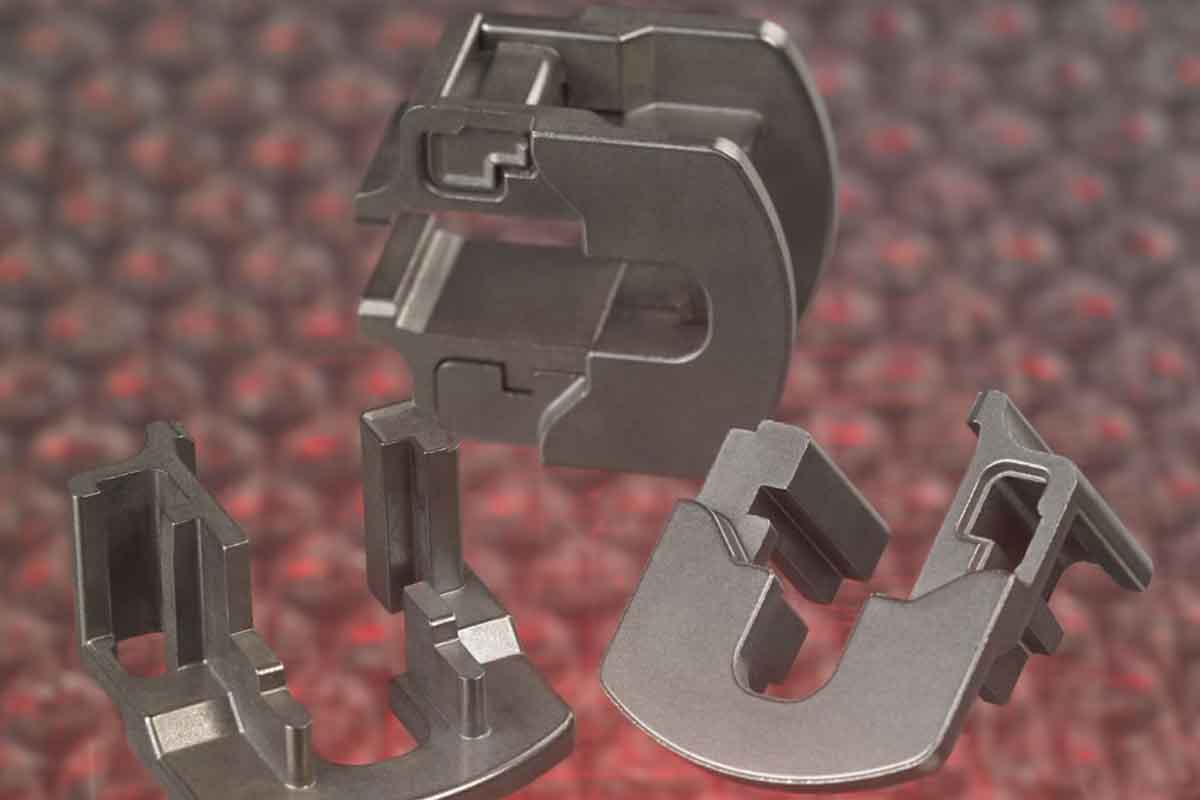

Lockset slide retractor

2 piece “puzzle” assembly Sintered copper steel Mirrored halves eliminate a costly rivet assembly operation Net-shape, sinter bonded ASCO Sintering Co., Commerce, Calif., received the Grand Prize in the hardware/appliances category for a lockset retractor assembly. The assembly functions as the heart of the mechanism in a heavy-duty door lockset system. Its