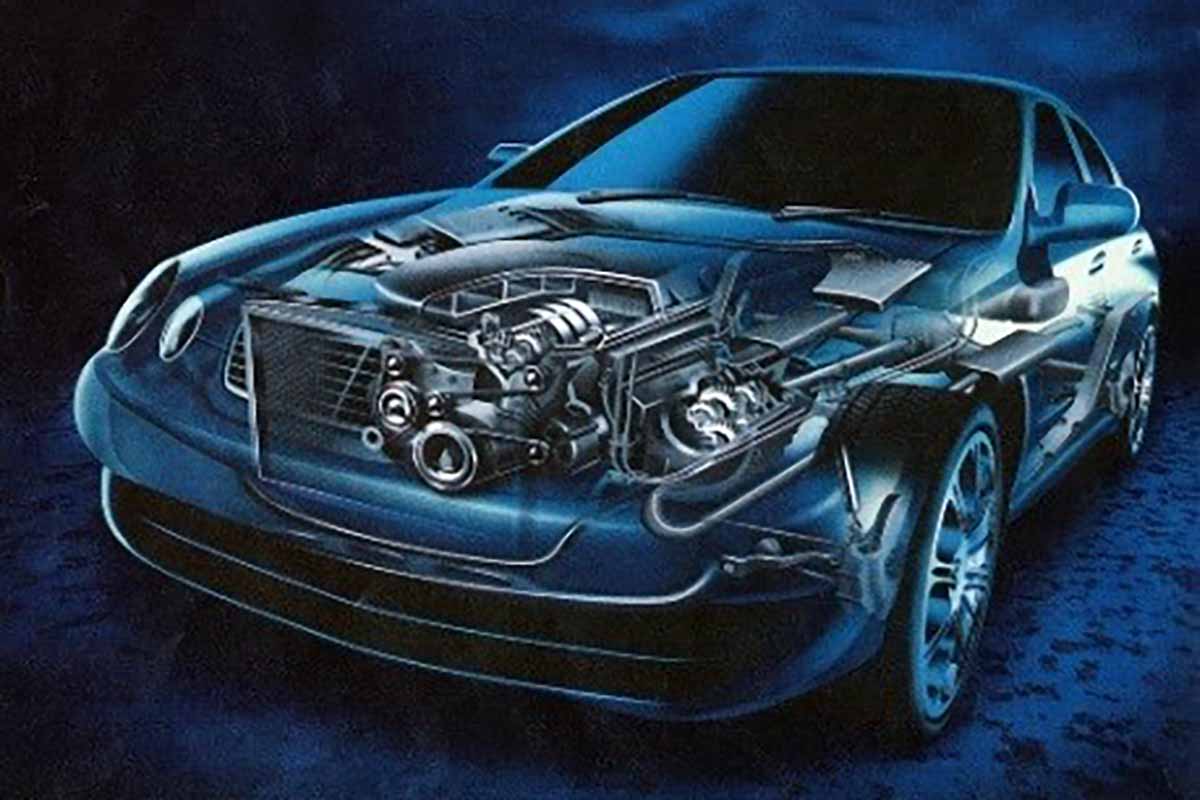

Minivan door clutch assembly

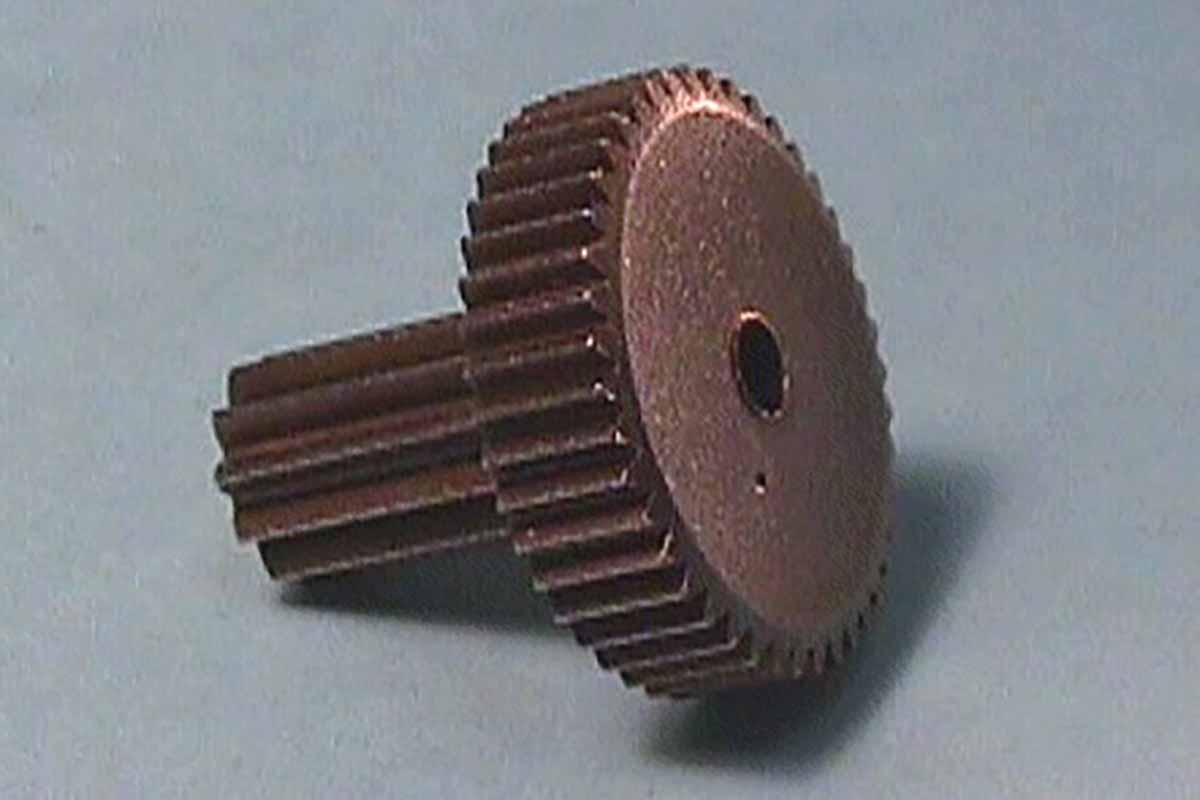

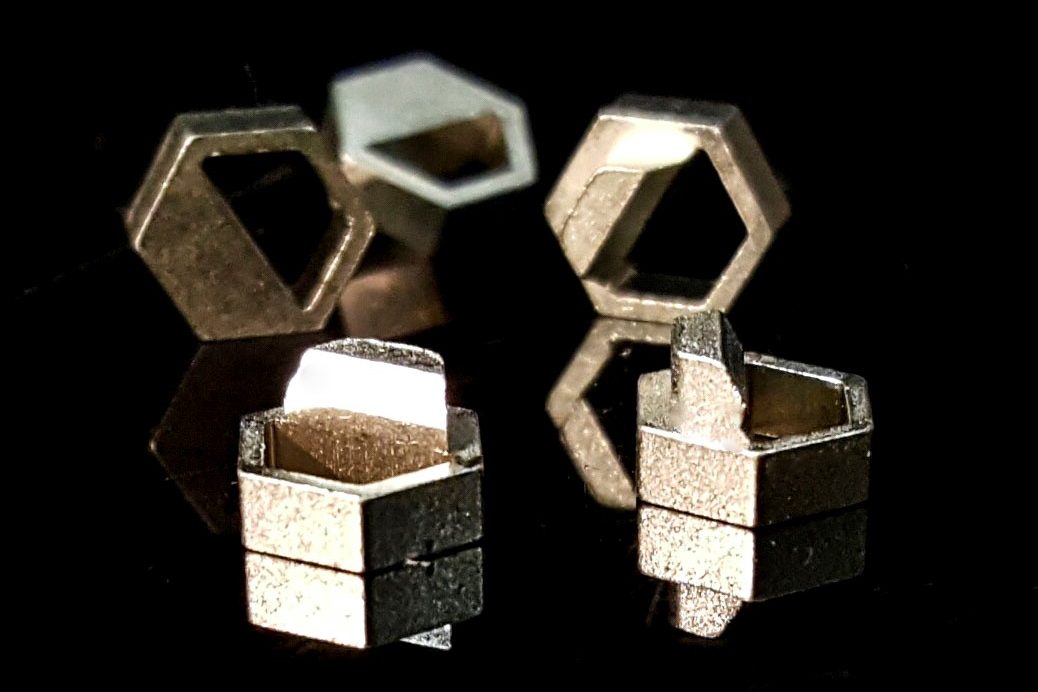

Rotor & Armature with posts and fine pitch matching tooth geometry Soft Magnetic Phosphorous Iron AGMA 8 pinion gear Hybrid Low Alloy sintered steel CLUTCH ROTOR ASSEMBLY ASCO Sintering Company, Commerce, CA. won the grand prize in the ferrous category for a gear assembly, consisting of four parts – an armature, rotor