Do You Have A Construction Project We Can Help With?

Press release 2017 MPIF Award

ASCO Sintering Co. wins 2017 Award of Distinction from MPIF for a copper-infiltrated steel latch bolt for a commercial door lock assembly Sam Moorman, Senior Process Engineer, ASCO Sintering Co., California, USA accepted an Award of Distinction in the Hardware/Appliance

South Africa Design Seminars

ASCO Sintering Co. to host Powder Metallurgy Design Seminars across South Africa in November of 2017 ASCO Sintering Co. is pleased to announce it has scheduled a series of Powder Metallurgy (PM) Design Seminars to be held in various locations

Events & Trade Shows

Upcoming Events over 3,000 pm sintered metal design solutions implemented during its 70 year history an industry record number of metal powder industries federation design for excellence awards cost savings estimated

Conventional Powder Metallurgy (PM) Process

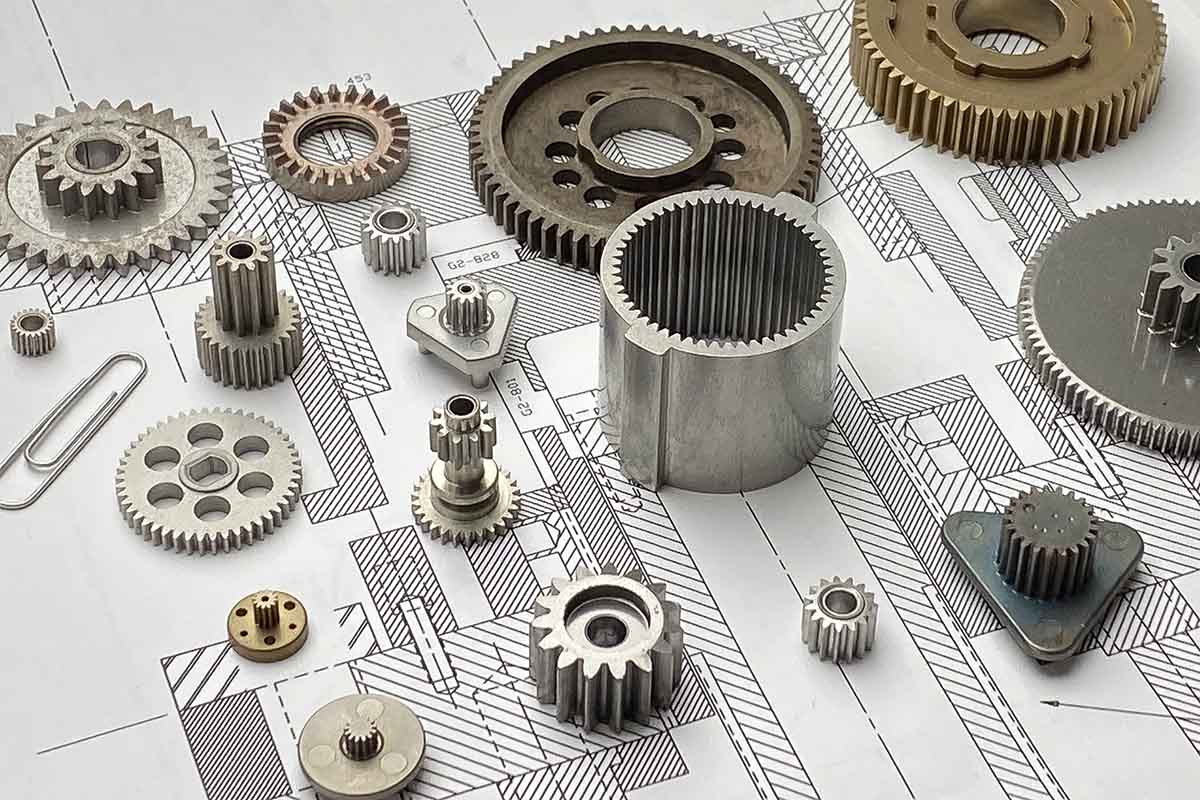

CONVENTIONAL PM PROCESS Also known as press-and-sinter, the process consists of mixing elemental or alloy powders with lubricants or additives to produce a homogeneous mixture. Additives may help improve machinability, wear resistance, or lubricity of the part; compacting the mixture in

Advantages of Powder Metallurgy (PM)

ADVANTAGES OF POWDERED METALLURGY Powder metallurgy is a well- established mass production method for structural parts, bearings, filters, tool parts, magnets, friction materials, contact elements and components from refractory metals. Its basic steps are powder production, mixing, molding

When to use Powder Metallurgy (PM)?

WHEN TO USE PM When to use PM is a commonly asked question. As you would expect there is no single answer, but here are some general guidelines.To make a PM part requires tooling. The cost of