- Frangible bullets

- Compacted copper powder

- Net shape, low cost

- Multi-cavity tooling design results in cost reduction

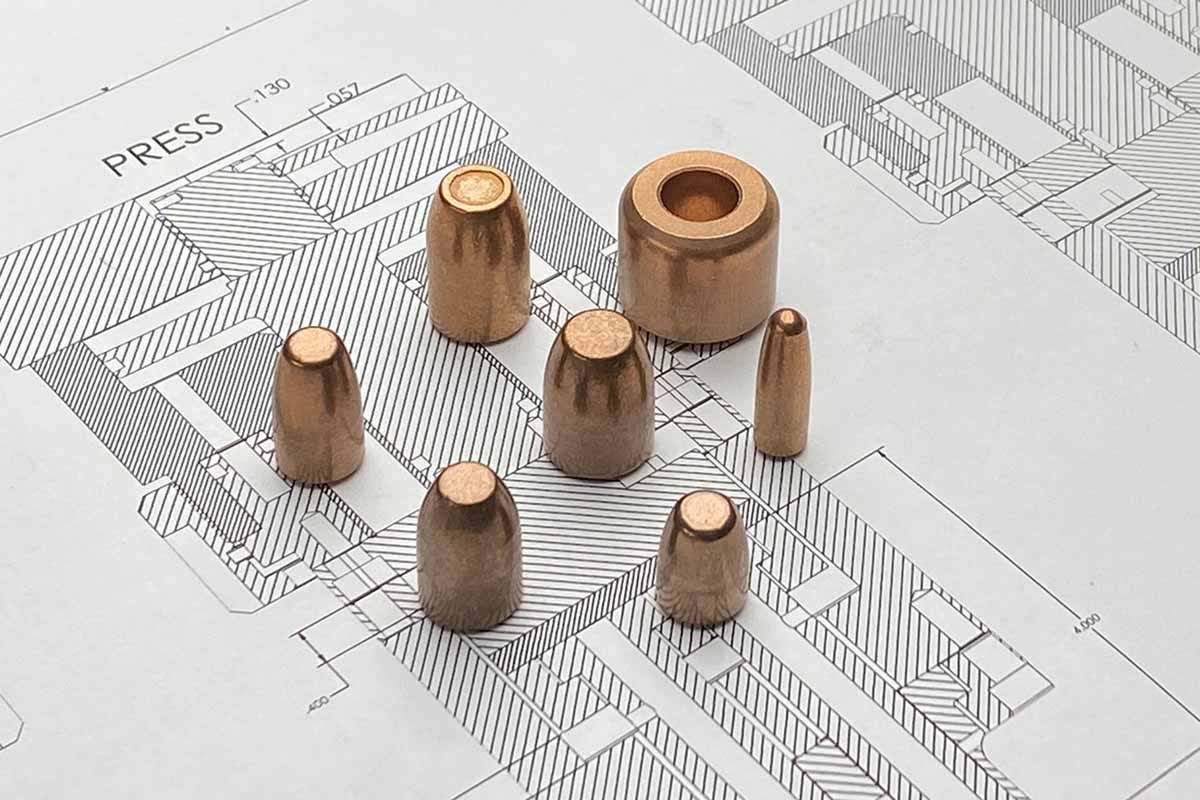

Frangible bullets made of powdered metal. ASCO Sintering using copper alloys as the most common element is powdered copper. The powdered material is compacted into various shapes and densities.

Frangible bullets hit the target less than lead bullets because after the disintegration, the causing particles have less mass and therefore less momentum to drive them through a medium.

Using conventional powder metallurgy to manufacture frangible bullets allows producing parts to lower density. That helps to disintegrate into powder on impact

ASCO Sintering offering to manufacture Frangible bullets:

- Compacted copper powder

- Net shape, low cost

- Multi-cavity tooling design results in cost reduction

- Tonnage monitoring at press that manufactures frangible ammunition, to keep consistent weight from bullet to bullet,

- SPC (Statistical process control)

Frequently asked questions about frangible ammunition

Question: What is most used material to make Frangible bullets?

Answer: most common material is Bronze: 90% Copper (Cu), 10% Tin (Sn)

Question: What is the Density of Frangible bullets?

Answer: usually we make it to 6.9-7.5 g/cc

Question: What Density Frangible bullets made of ?

Answer: usually we make it to 6.9-7.5 g/cc