Bevel gears

- Provides 90 degree actuator motor directional drive change

- Heat treated Copper Infiltrated PM steel

- Net shape bevel gear geometry

- 50% Cost saving Powdered Metal process over traditional gear cutting technology

Double gears

- AGMA 8 Flange & Pinion gear combination

- Sinter Hardened Nickel steel alloy

- High strength torque & mechanical properties

- 100% Resonant NDT Qualified

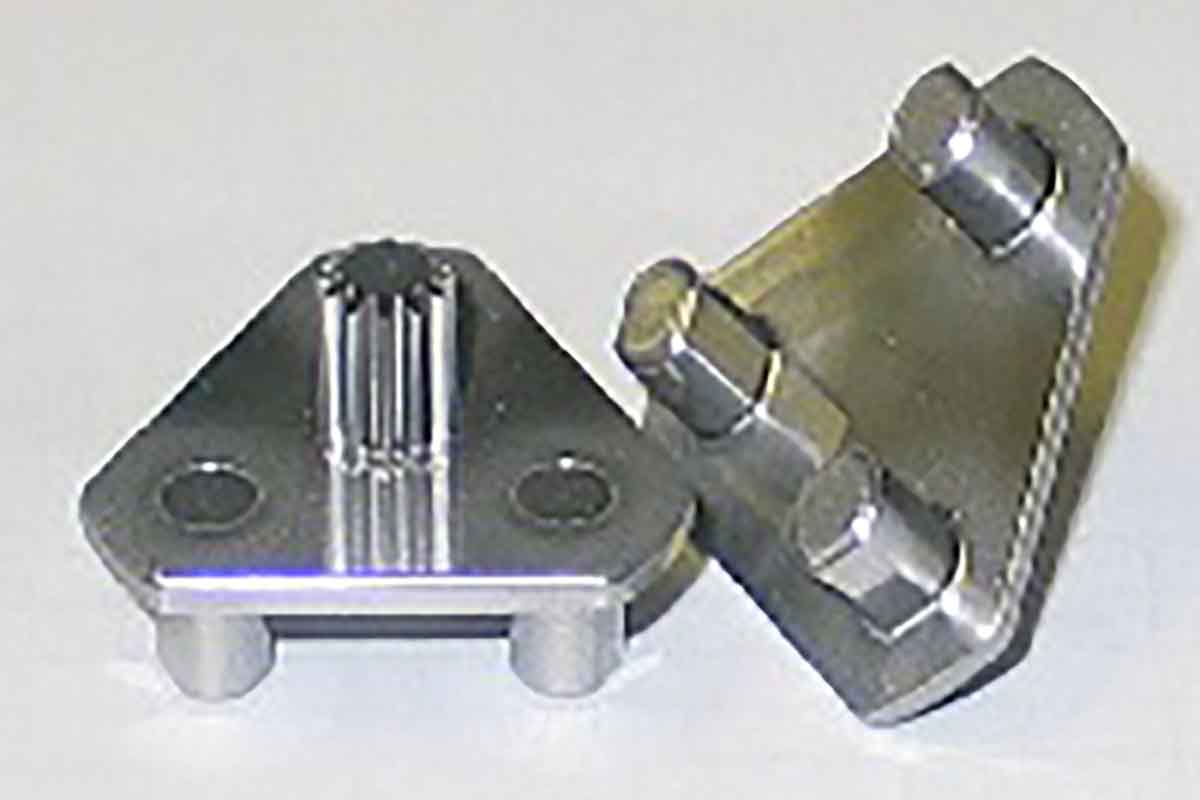

Gear carriers with integral posts

- Actuator motor applications for many industries

- Sinter Hardened Nickel steel

- Net shape tool design provide 75% cost saving over machining

- 100% Resonant NDT Qualified for Gear & Posts to Flange integrity

Spur gears

- AGMA 8 level METRIC Gears

- Sinter hardened nickel steel minimizes processing steps

- Multi-cavity tool design provides 50% cost savings with sintering process

- MPIF Design Excellence winner for powder metallurgy parts and solutions

- Maximum Cost Savings

- Tight tolerance capability

- Six Sigma and lean manufacturing methodologies

- Collaborative creative tooling design

- High performance engineered materials