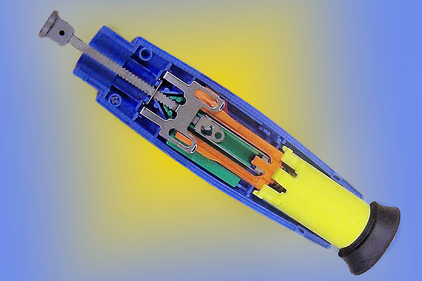

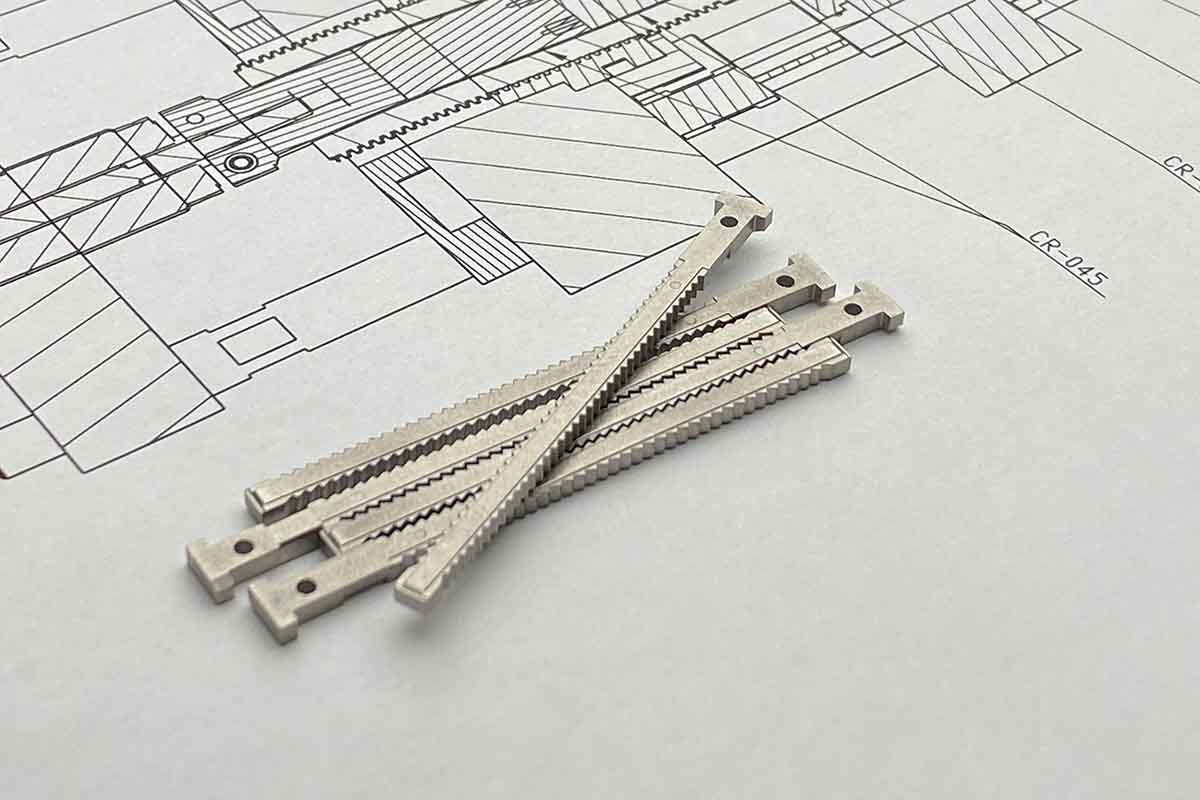

ASCO Sintering Co. manufactures stainless steel ratchets. The osteoporosis pen ratchet serves as an indexing component in an at home prescription drug delivery system.

Each tooth represents the daily dose of a prescription osteoporosis medication.

With density of 6.5 gr/cc and UTS of 41Ksi, ASCO’s 316 stainless steel ratchet replaced a nylon version that did not have adequate mechanical properties.

ASCO uses a combination of unique tool design, robotic material handling and tightly controlled processing to economically manufacture this critical component which most would consider a more expensive MIM part.

THE MOST OFTEN ASKED QUESTIONS ABOUT P/M

Question: How big can PIM parts be?

Answer: That depends on several things; but the press size, square inch area of the face of the part, and the material are basic. 200 ton press can produce parts up to 16 sq. ins. Stainless steel presses at 40-45 T.S.I., so that same press can make a stainless steel part between 4 and 5 sq. ins. Brass, bronze and ferrous metals fall in between these two examples.

Question: Where are the parting lines on P/M parts?

Answer: There are none! Parts are pressed from both the top and bottom in a die, then ejected up out of the die. for more information you can download “Powder Metallurgy Design Guideline” (see Free Design Guideline)