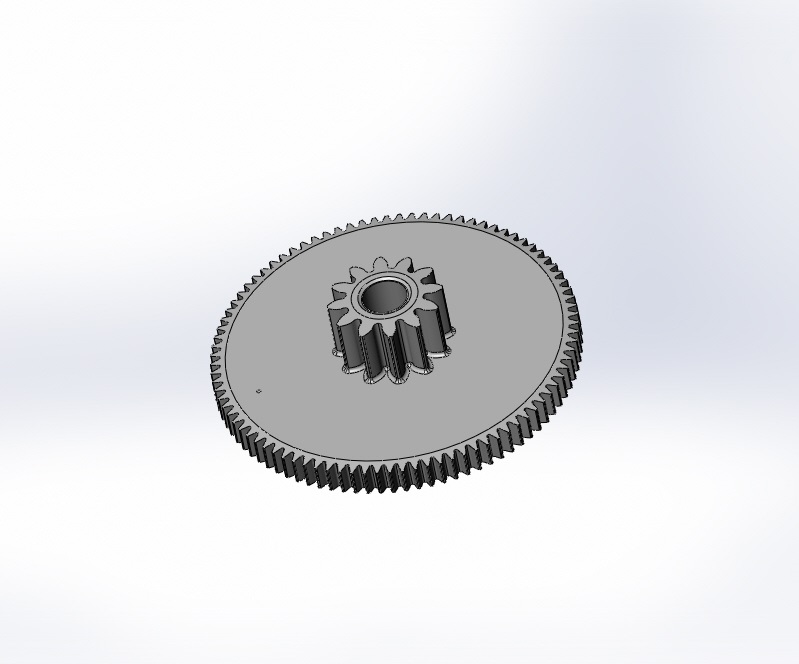

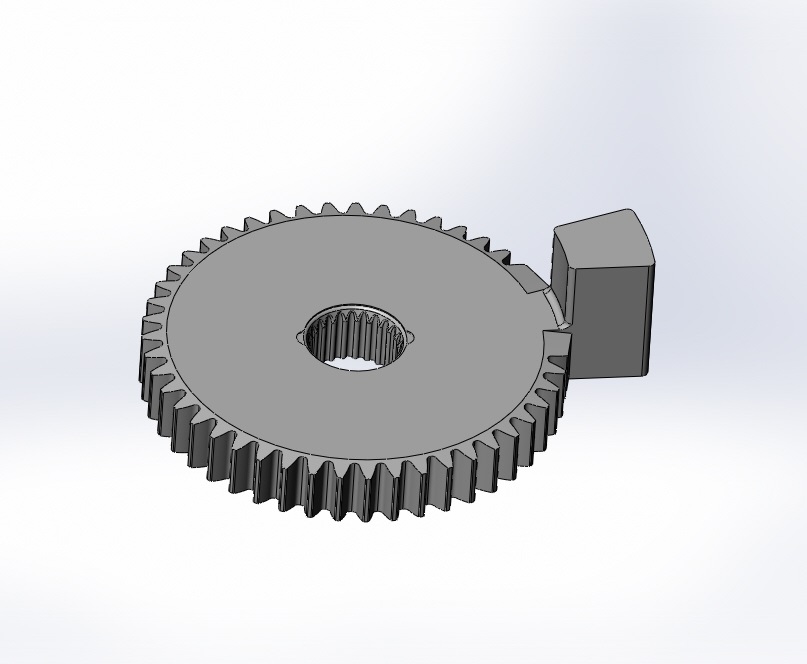

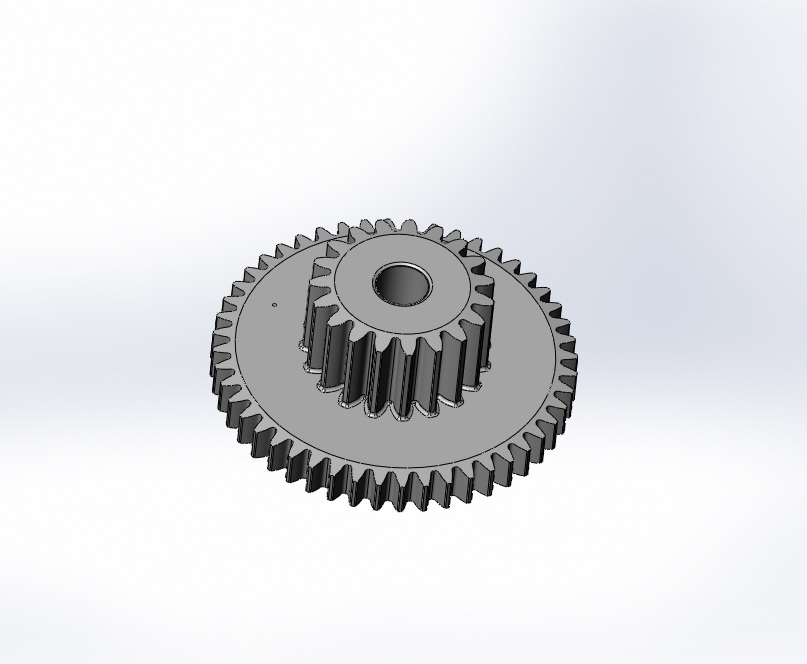

- Compound AGMA 8 gears

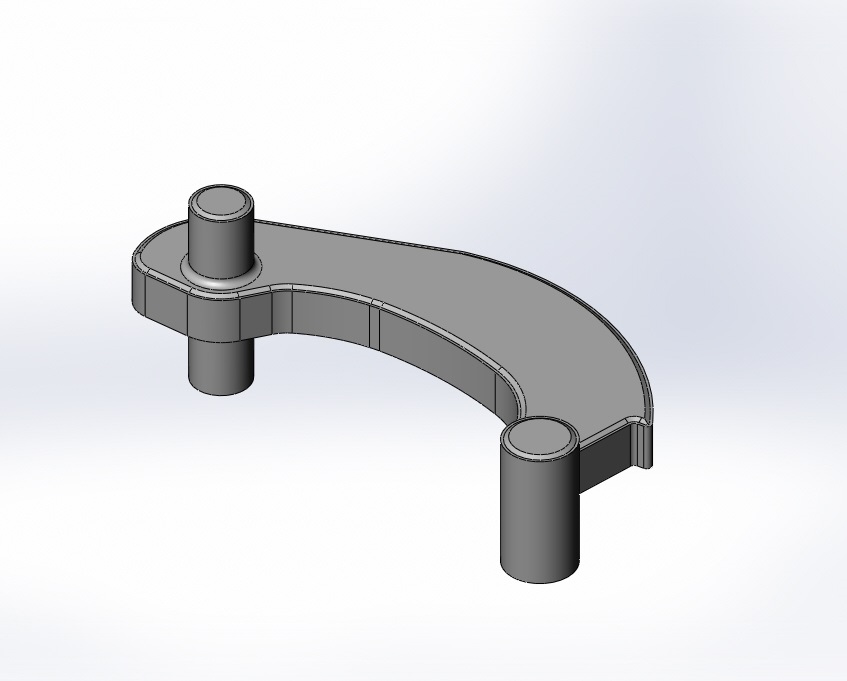

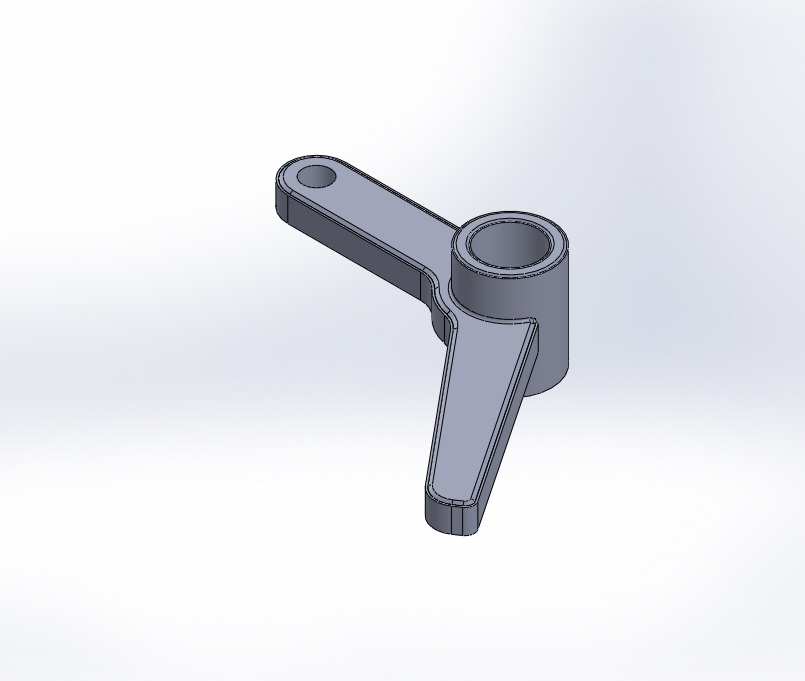

- Trigger Arms and Links

- Sinter-Hardened Nickel Steel

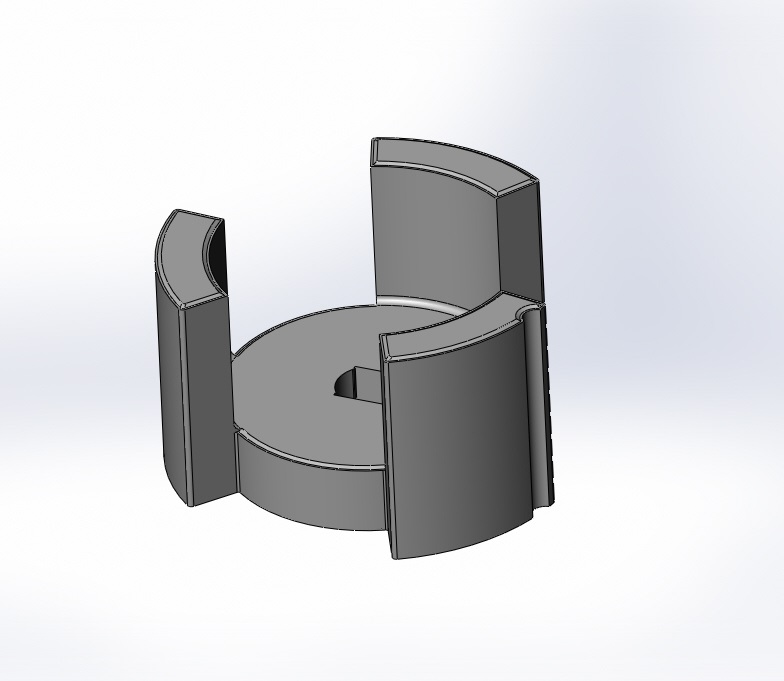

- 316 Stainless Steel Couplings

- 100% Non-Destructive Tested

ASCO Sintering Co has now produced over 2,000,000 sintered components for the current GM SBW Actuator assembly. The combination of gears, trigger links, trigger arm and couplings are assembled to allow effortless automatic transmission shifting. Conventional Powder Metallurgy PM produced parts provide over a 25% cost saving when compared to traditional manufacturing processes such as turning, milling or EDM.

The 1st stage Compound Gear, Output Gear, Trigger Arm and Trigger links made from Sinter Hardened Steel minimize the Defective Parts per Million Opportunity DPMO because operation steps are reduced by ½ when compared to traditional PM Material processing.

Furthermore these PM Design Solutions are pressed net shape with Statistical Process Controls applied throughout the Compacting and Sintering processes to achieve 6sigma Quality levels. Geometries identified through Failure Mode Effects Analysis FMEA as high risk failure potential receive 100% Non-Destructive Resonant Testing to ensure shipment of defect free product.

The 2nd stage Compound Gear made from near fully dense proprietary ASCO HI-IMPAC Copper-infiltrated Powder Metallurgy steel, provides superlative impact toughness and ultimate tensile strength that far surpass similar materials published by the Metal Powder Industries Federation MPIF Standard 35 for PM Structural Parts

Finally the Sintered Stainless Steel Coupling combines state of the art fluidized powder die filling technique with a proprietary triple upper actuating mechanism to achieve extensive powder transfers and fill compensation, delivering a part with uniform density distribution essential to reducing distortion during the Sintering process.

These sintered solutions provide over a 25% cost saving when compared to traditional manufacturing processes such as turning, milling or EDM and continue to demonstrate why Employee Owned ASCO Sintering Co. is considered one of the World’s leading experts in Conventional PM parts manufacturing.