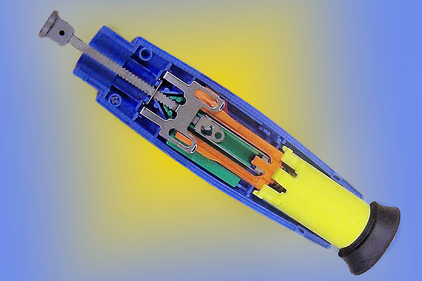

ASCO Sintering Company, Commerce, CA has supplied a selection of different fuse rotor designs, for the US Army M549, M549A1, and M550, 40mm and 50 mm high and low velocity rounds, for over 30 years. These highly detailed precision components are assembled with a segment gear to house a detonator. The assembly provides the time delay necessary to move the munition projectile from an unarmed to armed state after impact.

The rotors are made from a proprietary 80/20 Sintered brass material that provides the ductility, elongation and strength necessary for consistent and reliable and quality performance. The material is processed to density of 8.0 grams/cc, has an ultimate tensile strength of 35 KSI and an apparent hardness of 82 HRH.

The rotors are inspected for shear and ductility to ensure successful function during the swaging assembly operation. All but the 40mm high velocity rotor, which is drilled at a compound angle and 100% verified by a 100% fully automated in-line vision system, are produced net shape.