The world of metal manufacturing is constantly evolving, and one of the most popular materials is powdered metal. There are many advantages of powdered metal that make it a great choice for the manufacturing industry.

In this article, we will go through the main advantages of powdered metal and what powder metallurgy benefits you can get through the process.

Keep reading!

7 Significant Advantages of Powdered Metal

Here are the top advantages of powdered metal:

#1 It Produces Less Scrap

Powder metallurgy produces significantly less scrap in the process than machining. The particles of powder are strong and cohesive, so they stick together for long periods without falling apart. As well as preventing waste from production machines, powdered metal also reduces energy wastage during machining.

#2 It Saves Time

Machining metal can require a lot of time and effort, as well as money. On the other hand, Powder processing removes the need for machined parts altogether by mechanically producing powdered metal in one step.

Powdered metallurgy is great for producing parts in bulk. Hence, it significantly improves production output in many industries.

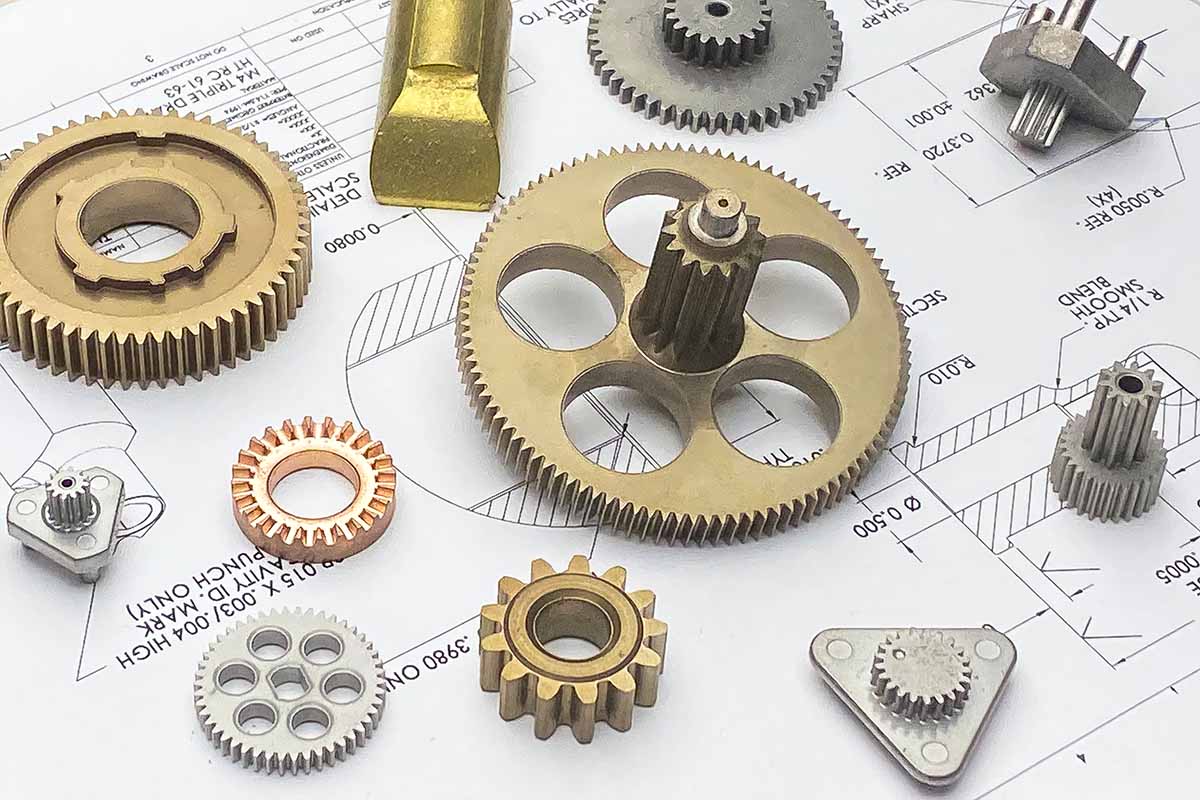

#3 It Provides High Precision

Powdered metal has gained a lot of popularity as it provides high precision and control.

Powder metallurgy saves extra work by producing exact dimensions. Therefore, the parts are highly accurate and exact due to precise powder measurements. Hence increasing quality and reducing defects in the final product.

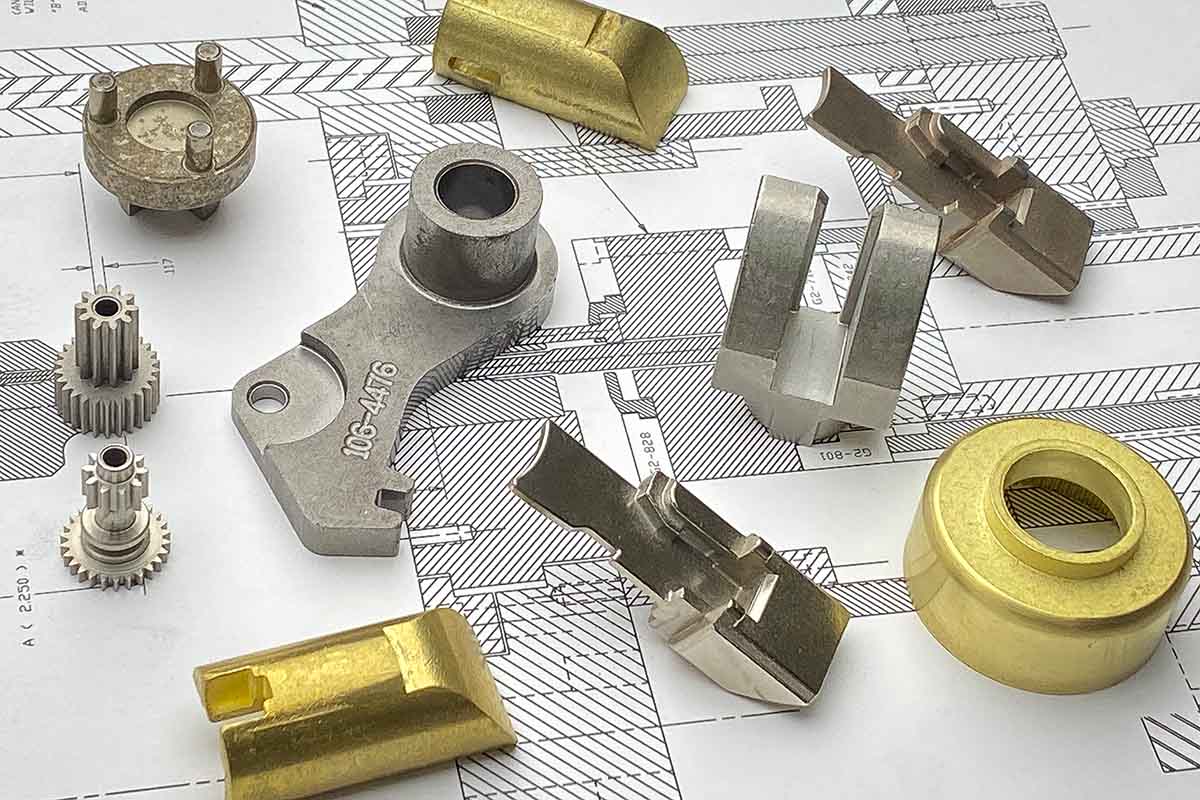

#4 It Provides More Strength

Powdered metallurgy produces mechanically strong and hard materials. They will not dent easily and hold their shape for a long time, unlike machined parts made by conventional methods. Hence, manufacturers need to invest less in machining and can produce more with the same resources as powder metallurgy makes.

Remember that advanced sintering technology allows powder metal components to be stronger than you expect.

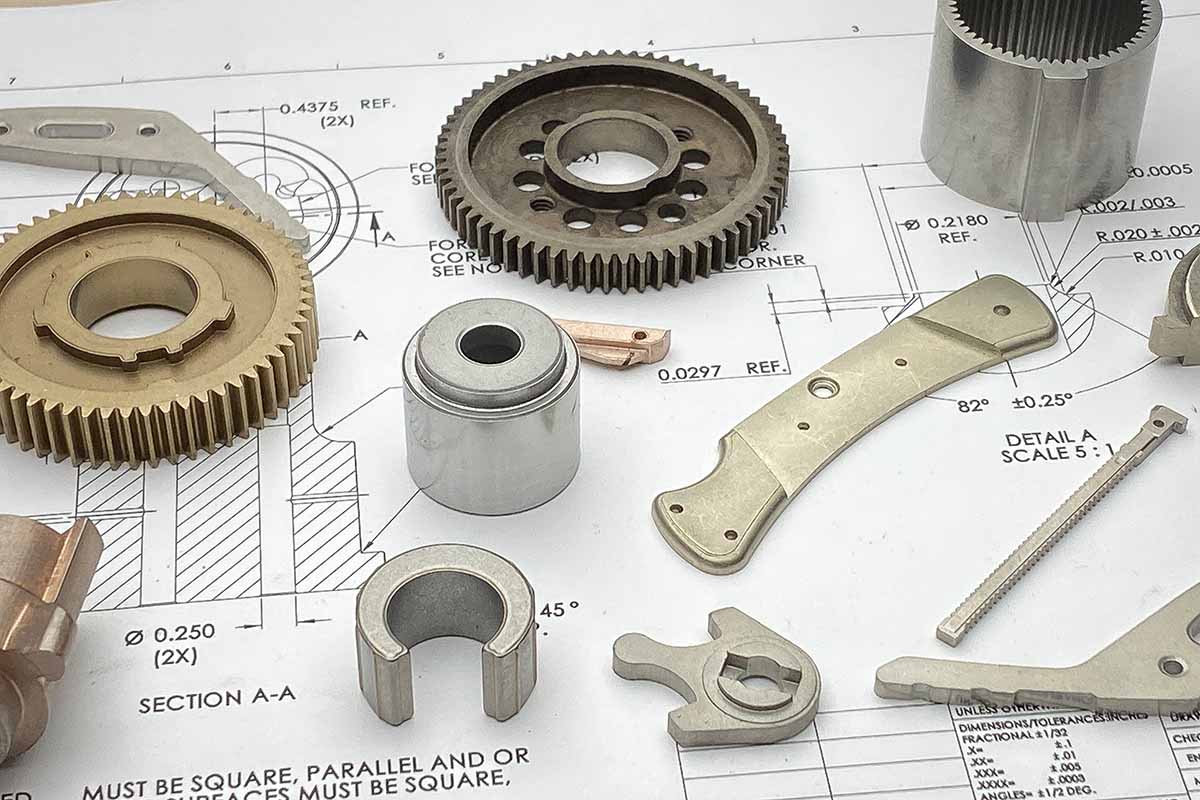

#5 Powdered Metal Has a Good Surface Finish

The powder melts into a uniform appearance, for an even surface of equal thickness. Different amounts of powder are added to create this finish. This surface finish helps to reduce wear and provide longevity. Powdered metal can be machined into many different shapes, producing parts that are highly aesthetic with quality workmanship and beauty.

#6 It Forms Complex Parts

Powder metallurgy provides metal parts with great complexity. Other metalworking processes can’t create such unique parts that people would think them impractical.

Powder metal manufacturing allows you to make all of your custom needs and ideas. Powder gives designers an opportunity to produce any shape they want even if the raw material doesn’t already have this shape’s inherent properties like hardness or toughness (strength).

#7 It Has Low Labor Costs

Powder metallurgy gives low labor costs as compared to conventional techniques. Since conventional machining requires skilled labor, it’s more costly than powdered metals.

Conclusion — Advantages of Powdered Metal

Powder metallurgy is a manufacturing process that uses powders to create metals and alloys. It offers several advantages over other manufacturing processes, including improved strength, durability, and resistance to corrosion. Additionally, powder metallurgy is faster and less expensive than other manufacturing processes.

Powder metallurgy is ideal to create a variety of products, including aircraft parts, medical implants, and agricultural equipment. It is also used in the automotive, aerospace, defense, and industrial sectors.