Automotive gears are an essential part of any vehicle, and without them, the machine would be useless. Since automotive gears are made of different materials, they are designed for different industrial and consumer purposes.

In this blog post, we’ll be discussing a short introduction to automotive gears, their manufacturing, and their types.

Stay tuned!

Introduction to Automotive Gears

An automotive gear is a rotating part with teeth that meshes with another toothed machine part or gear and transfers torque.

Gears are an essential part of the operation of an automobile. They come in different types, each with its own specific function. For example, the gearbox transmits power from the engine to the differential, which helps the car move.

Understanding how automotive gears work is key to driving safely and efficiently. By understanding the different types of gears, as well as the functions they serve, you will be able to drive with confidence and efficiency.

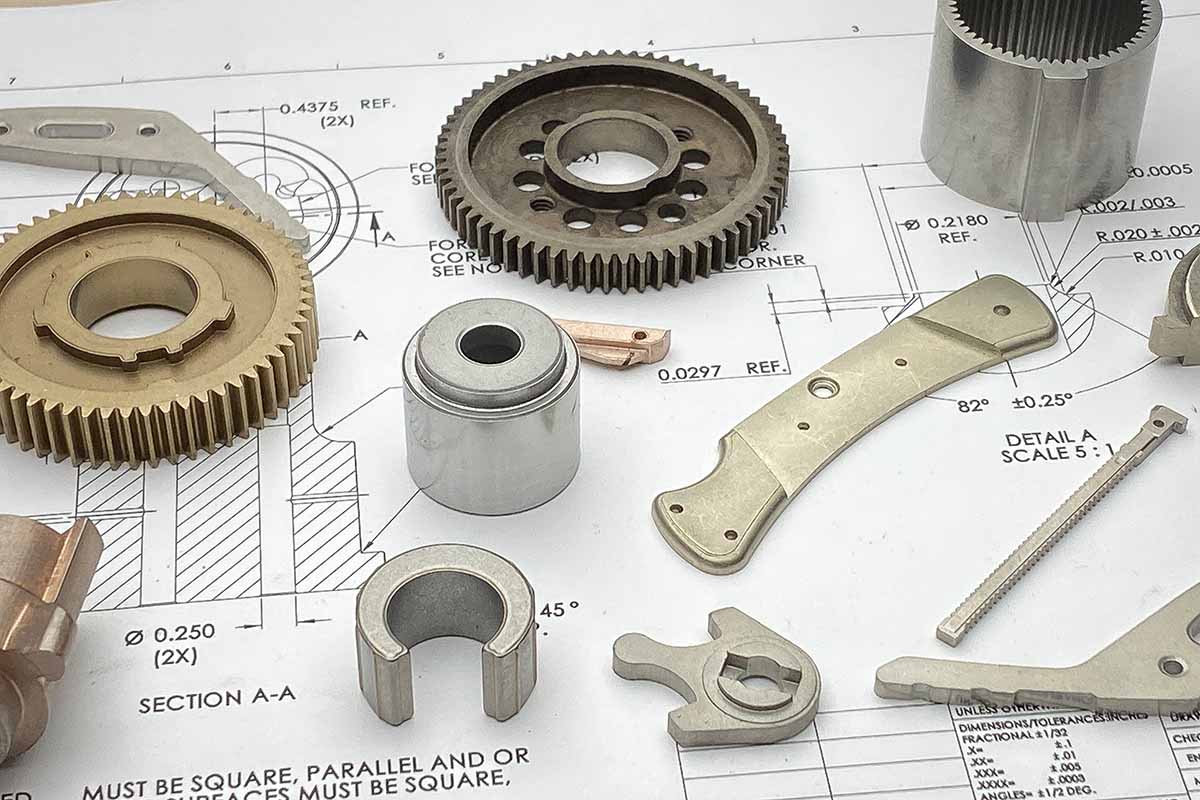

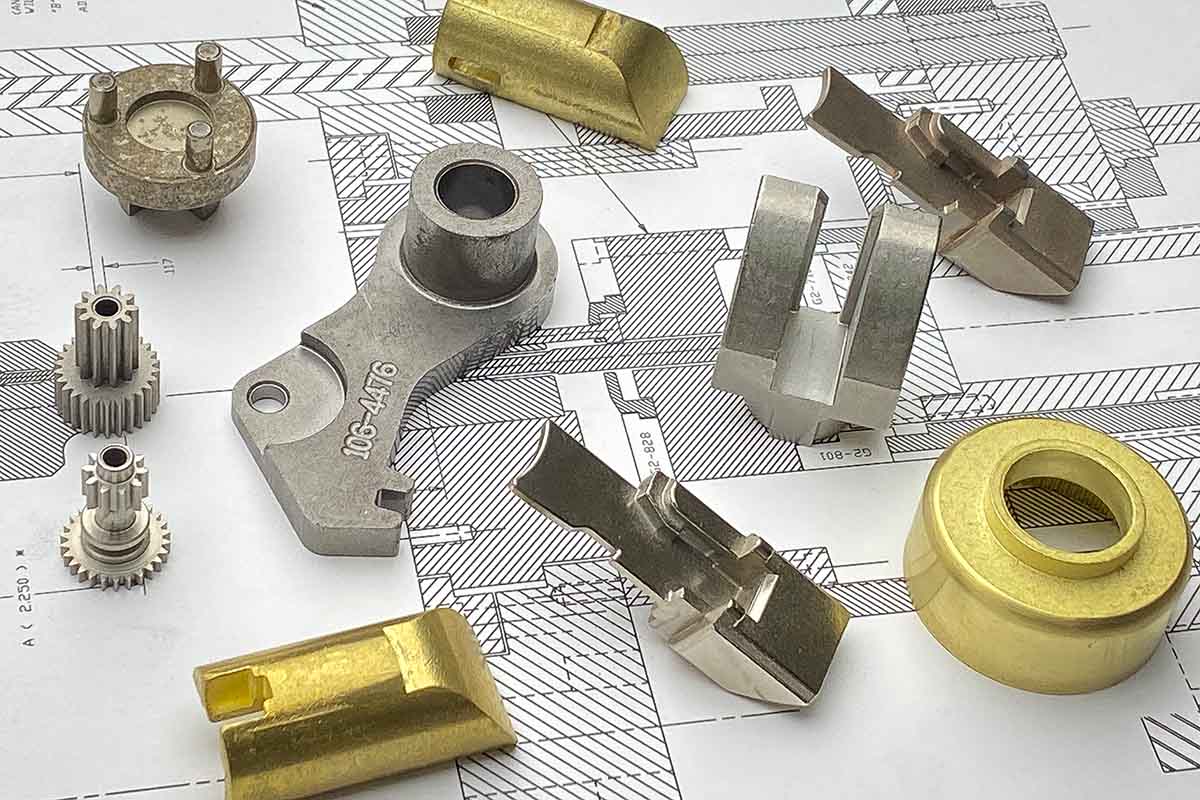

Automotive Gears Materials

Automobile gears are made up of various materials such as but not limited to:

- Steel

- Aluminum

- Brass

- Cast Iron

- Ductile Iron

- Powdered metal

- Plastic

- Bronze

However, the best material for automobile gears is an iron alloy. It gives most automobile gears the required strength and durability.

Automotive Gears Manufacturing

Gear making is an intricate and time-consuming process, but it’s what allows automotive vehicles to move smoothly and efficiently. Gears are made by different processes such as powdered metallurgy, casting, forging, extrusion, and blanking.

Machining is a common method for automotive gear manufacturing. In this process, plastic or metal parts are machined away, leaving a hollow part containing the gear teeth.

After that, gears require a certain level of finish. This may require processes such as heat treatment and surface finishing to achieve the maximum level of dimensional accuracy.

Sometimes, the manufacturer would require grinding, honing, or shaving the gear as well.

Types of Automotive Gears

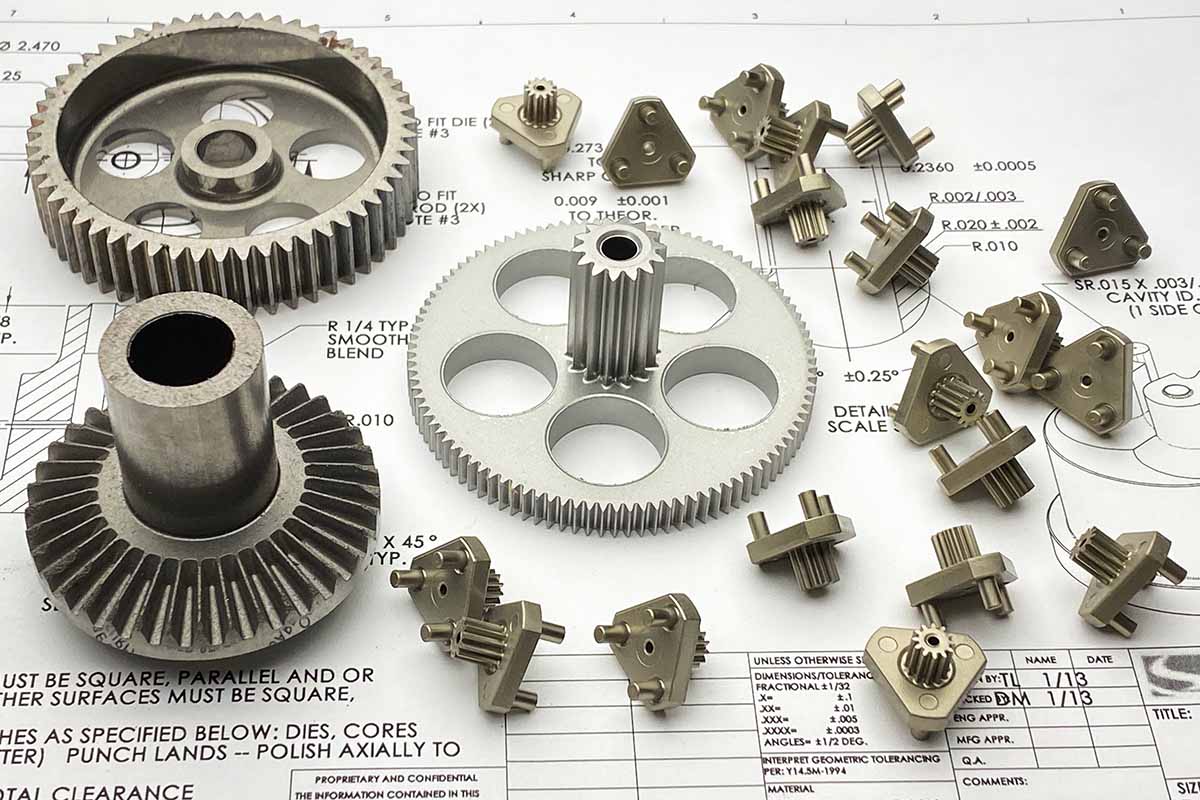

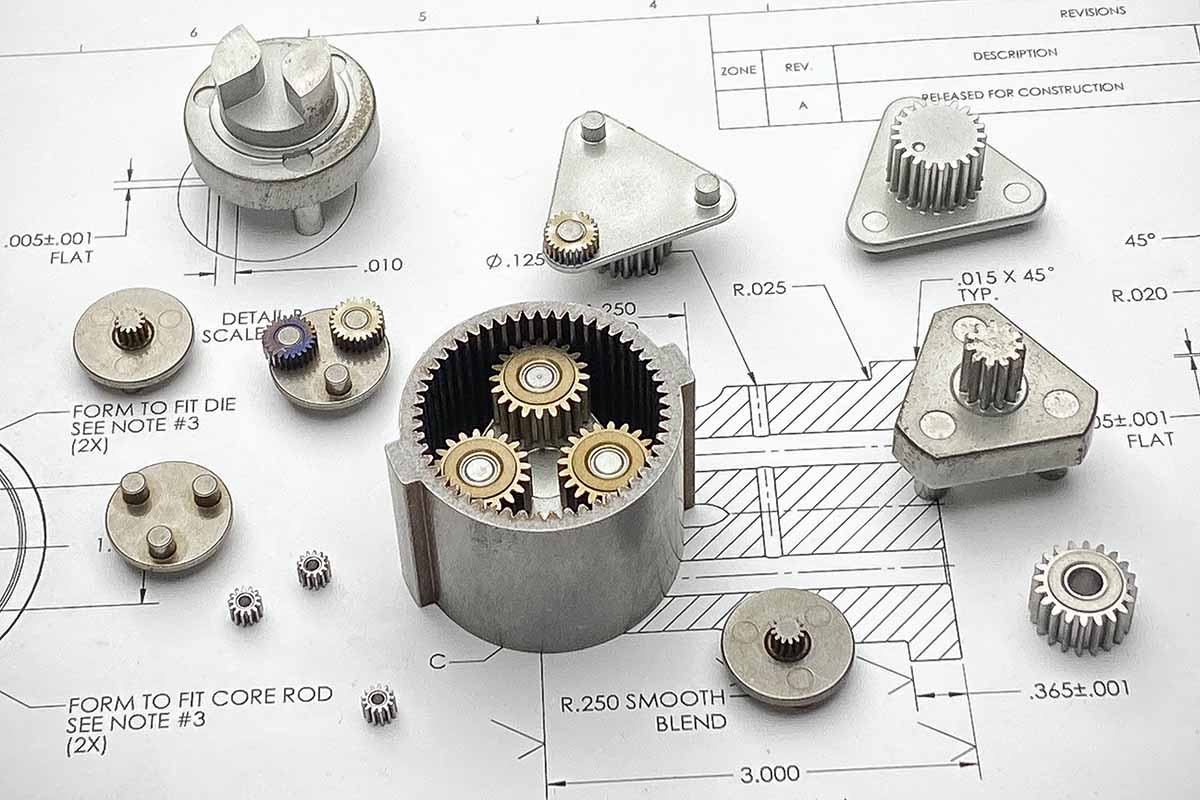

Here, we are going to discuss the five types of automotive gear.

Helical Gears

Helical gears are the most common type of automotive gear. They are best for high-speed transmissions as they offer less friction and wear than other common gears.

Bevel Gears

Bevel gears are common for railway track inspection vehicles, marine applications, and aircraft because they are good at managing high loads.

Spur Gears

Spur gears are similar to helical gears as they can handle a wide range of different speeds and loads.

Rack and Pinion

Rack and Pinion Gears are a combination gear system that includes a circular gear over a linear gear. The most common application of it is a vehicle’s steering mechanism. It’s also applicable in various industrial machinery.

Conclusion

Automotive gears can be a little daunting for the average person but don’t worry, you’re not alone — With all the different types, models, and designs of these products, it can be pretty confusing to decipher what each one to use.

Asco-sintering provides high-quality powdered metal gears and metal parts for the automobile industry. Hence, offering a wide range of custom gears to fit your special needs — Get your quote now by asco-sintering!