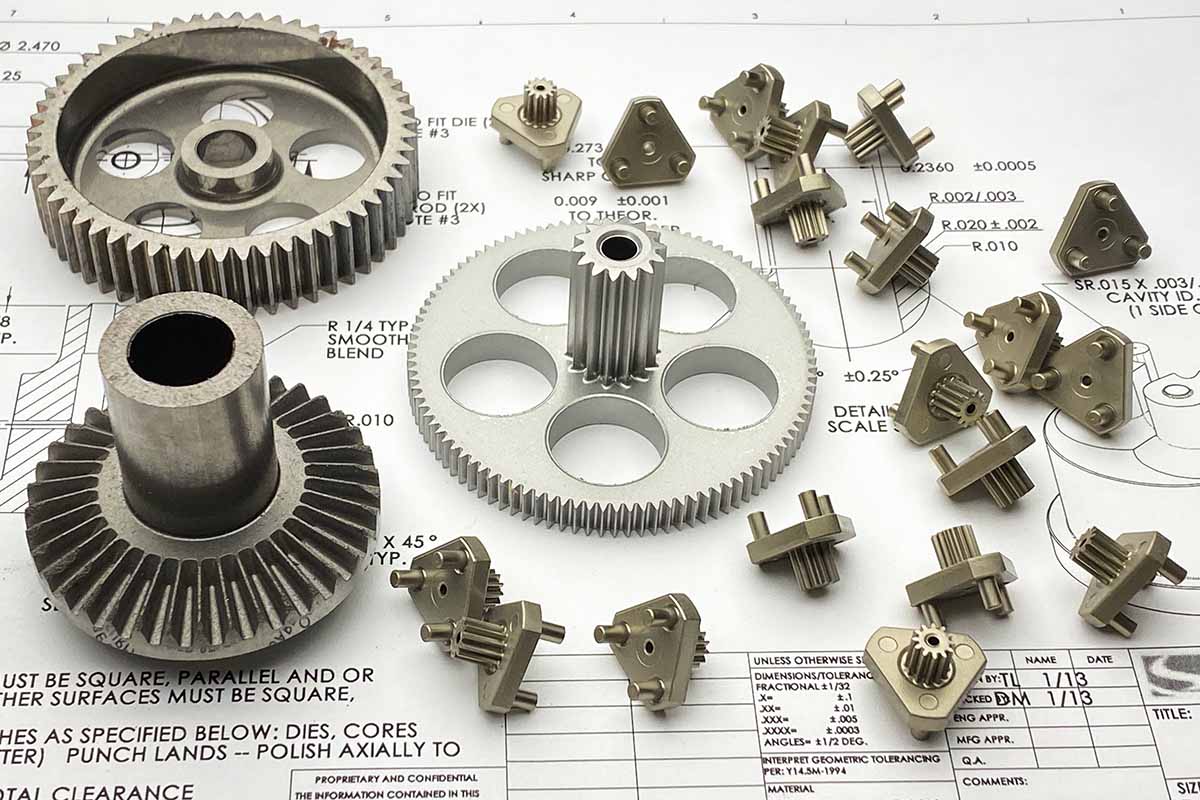

Modern engineering is incomplete without planet gear. They have been around for a few thousand years and are still an essential part of our daily life. There’s a decent chance that your car has planet gears if you drive it with an automatic transmission. In this article, we will explore what are planet gears, their benefits, and their applications — so that you understand the basics of planet gears and transmissions. Let’s go!

What is a Planet Gear?

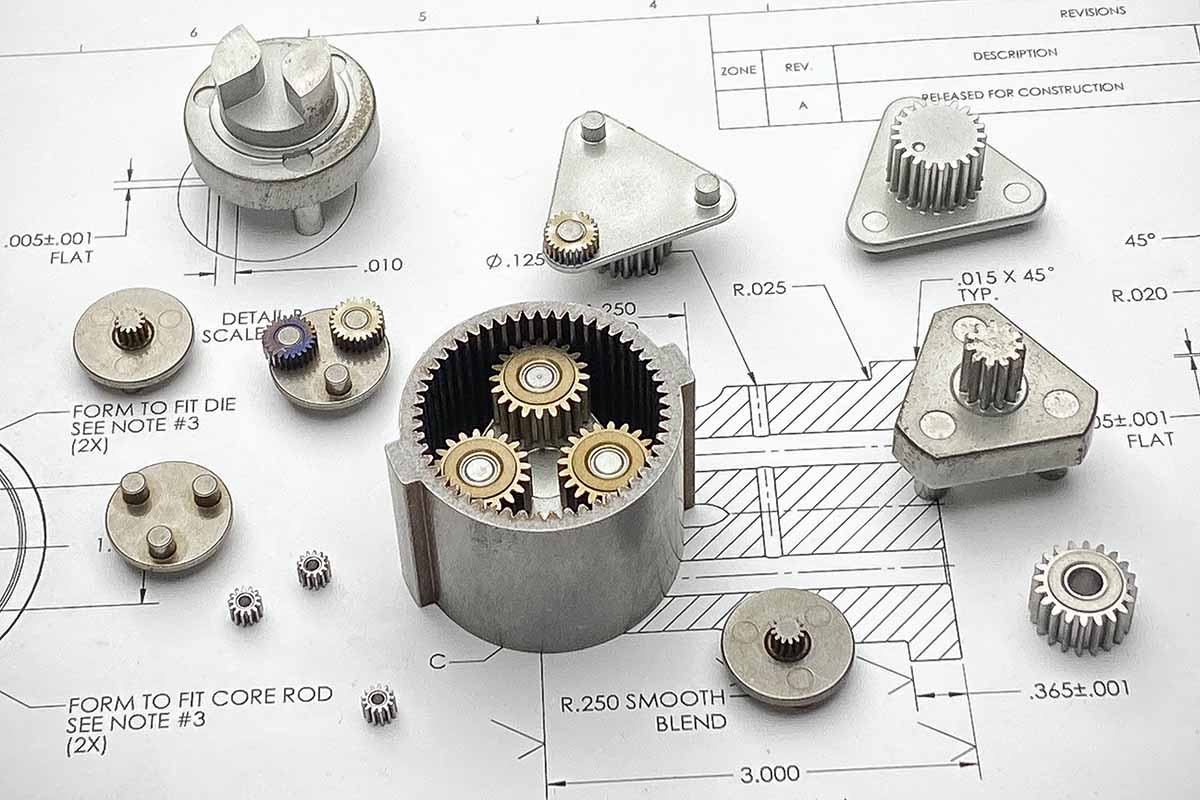

The planetary gear is a combination of multiple gears in which one gear revolves inside the other so that their pitch circle rolls without slipping. Planet gears are generally good for reducing speed. By decreasing the speed of the motor, planet gears increase torque. In other words, it helps increase the rotational working power of a machine. However, some industrialists use planetary gears as speed increasers too. It all depends on the application and the outcome you want to get from them. A planetary gear system consists of three gears:

- Sun gear

- Planet gear

- Ring gear

Planet gear is generally more expensive than other types of gear because they are more complex and require a fine level of precision. This level of sophistication is needed so that the planet gears will not lose their motion due to friction.

History

Greeks developed planet gears more than 2000 years ago. They replicated the style of motion of the sun and the planets to assess their orbital motion. However, the automotive field opted for planet gears in the early 1900s. Automotive engineers used planet gears in the Wilson-Pilcher automobile in the United Kingdom for the first time in its history. In just a few decades, planet gears became one of the fundamental parts of vehicles’ gearboxes. And now, almost no industry can run without them.

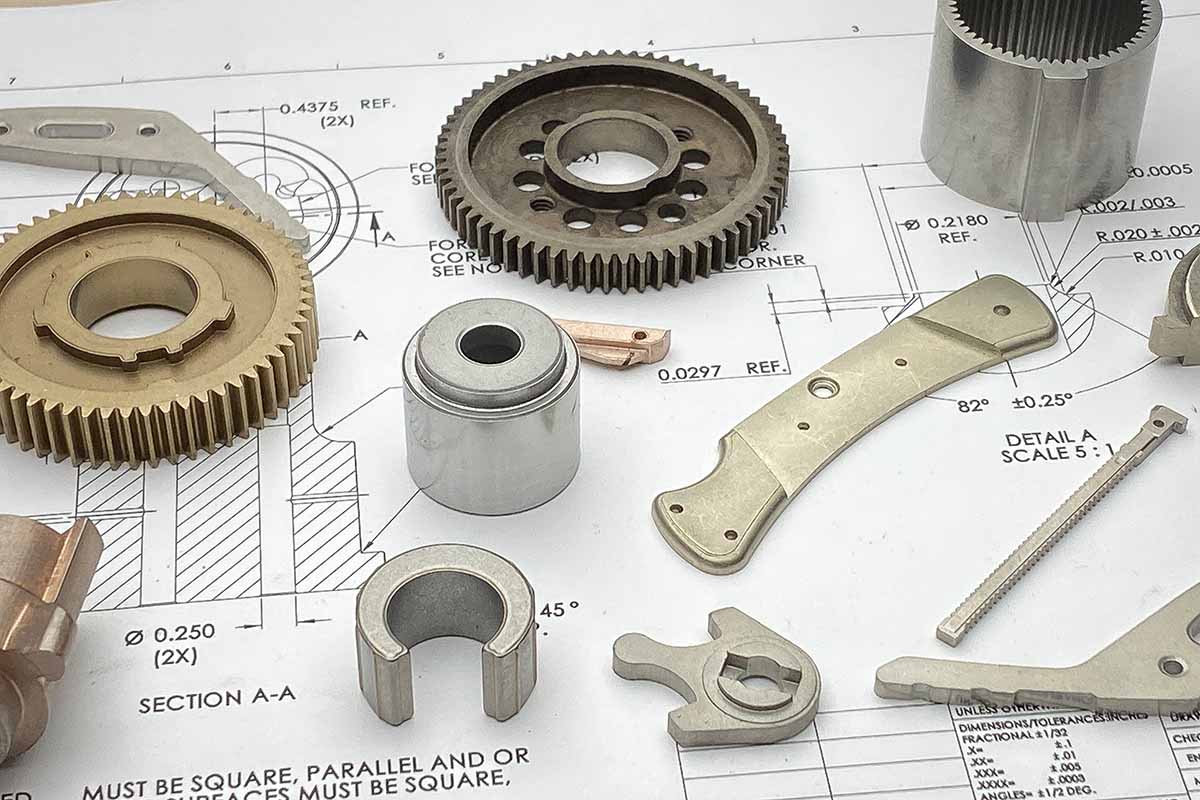

Industrial Application

Many types and brands of planet gears have been designed for Industrial purposes. Some of them are:

- Automotive

- Medical

- Agriculture

- Heavy Machinery

- Turbines

- Aerospace

- Pumps

- Robotics

- Conveyors

The hydraulic planetary automatic transmission, which is the most prevalent form of automated gear, is also based on the planetary gear principle.

Characteristics of Planet Gear

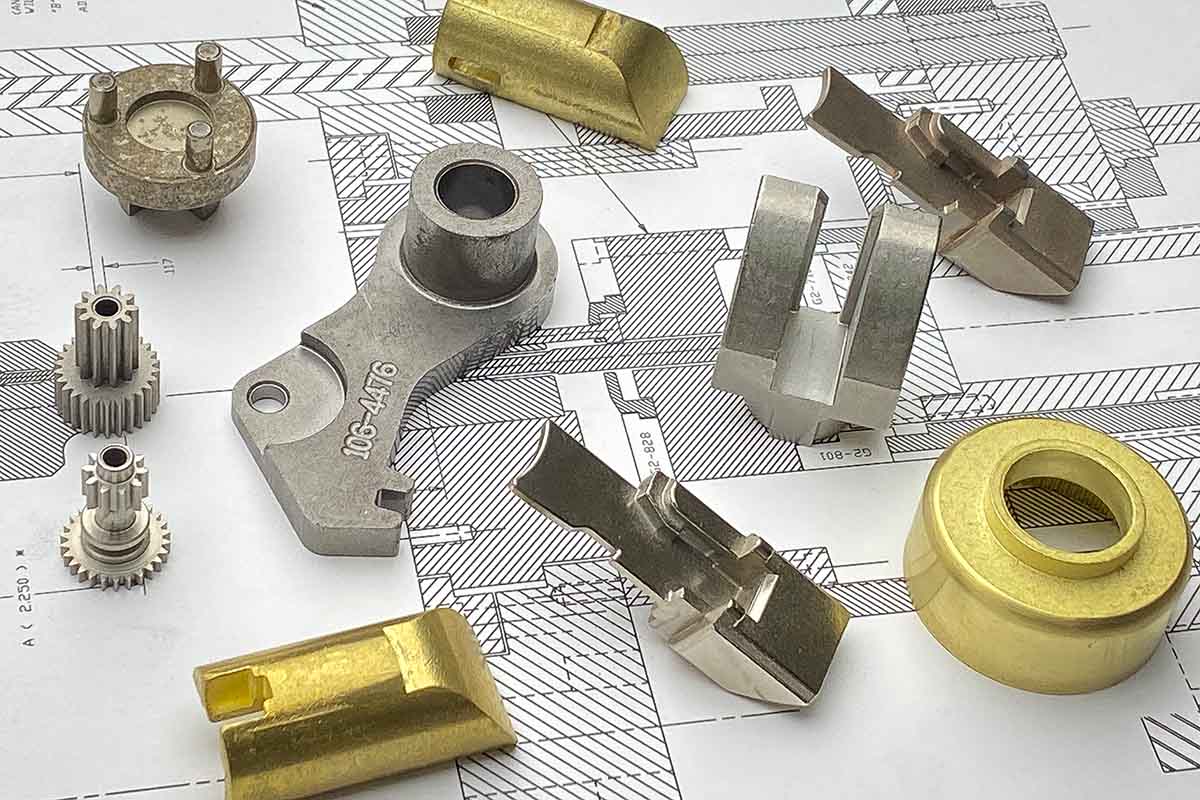

Planet gears are more robust and power-dense, allowing them to sustain greater torques and decreases in a smaller, more compact package. They offer easy ratio changes. Hence, a user doesn’t have to replace them completely when using a new application. Instead, he can just change the ratio within the planetary design. Planet gears are best for demanding conditions where you need to manage high shock loads. Just like any other gear, planet gears also need enough amount of lubrication and regular fluid changing to work properly.

Conclusion

Planet gears are among the most robust and versatile machine parts that exist in our current machine hosting industry. They are also ideal for manufacturing various others, powering heavy machinery, operating industrial equipment, etc. They play an inevitable role in mass-producing our world day after day. To learn more about planet gears and your specific needs, contact ASCO-sintering for a quick consultation.