- Continuous Belt Furnaces

- High Temperature Pusher Furnace

- Temper & Annealing Furnaces

- Coining, Plating, Machining

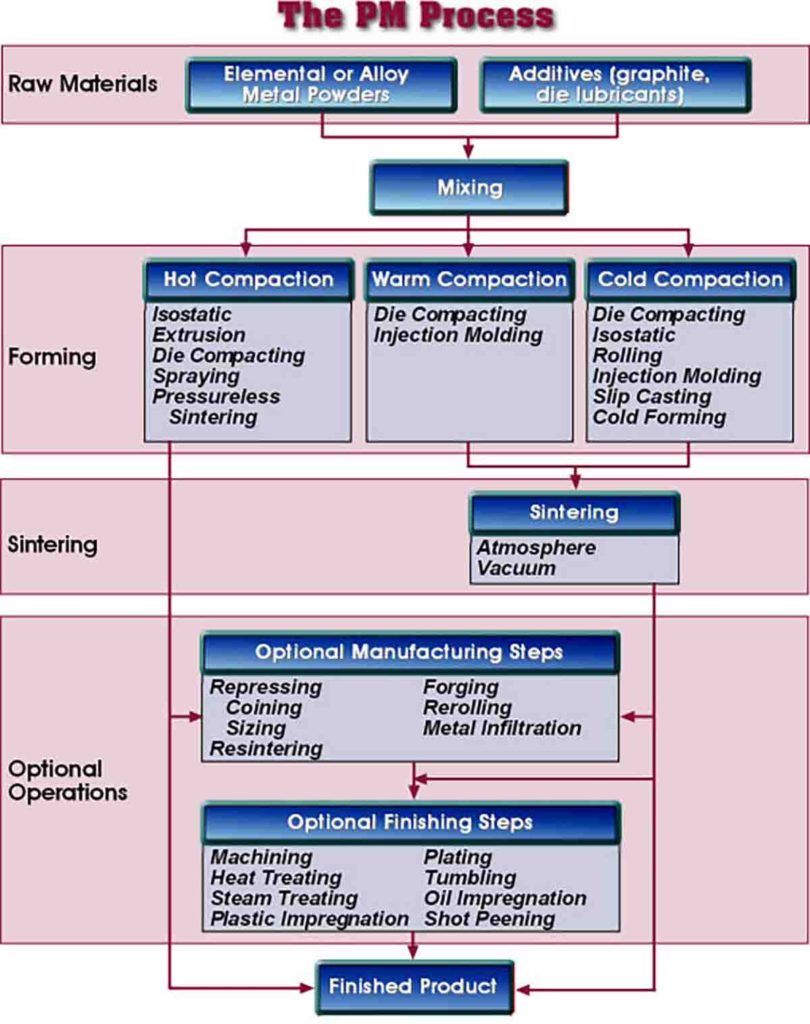

Sintering

The typical sintering step, the green compact, placed on a mesh belt, moves slowly through a controlled atmosphere furnace. The parts are heated to a temperature below the melting point of the base metal, held at the sintering temperature, and then cooled. Basically a solid-state process, sintering transforms compacted mechanical bonds between the powder particles into metallurgical bonds. This provides the PM part’s primary functional properties. Typical sintering temperature ranges are 1,450°F-1,550°F for bronze and 2050°F-2100°F for ferrous alloys. Throughput varies with part size, belt width, and belt speed, reaching as high as 1,000 LBS/hour (450 Kg/hour) in large furnaces.