Powder Compression Molding

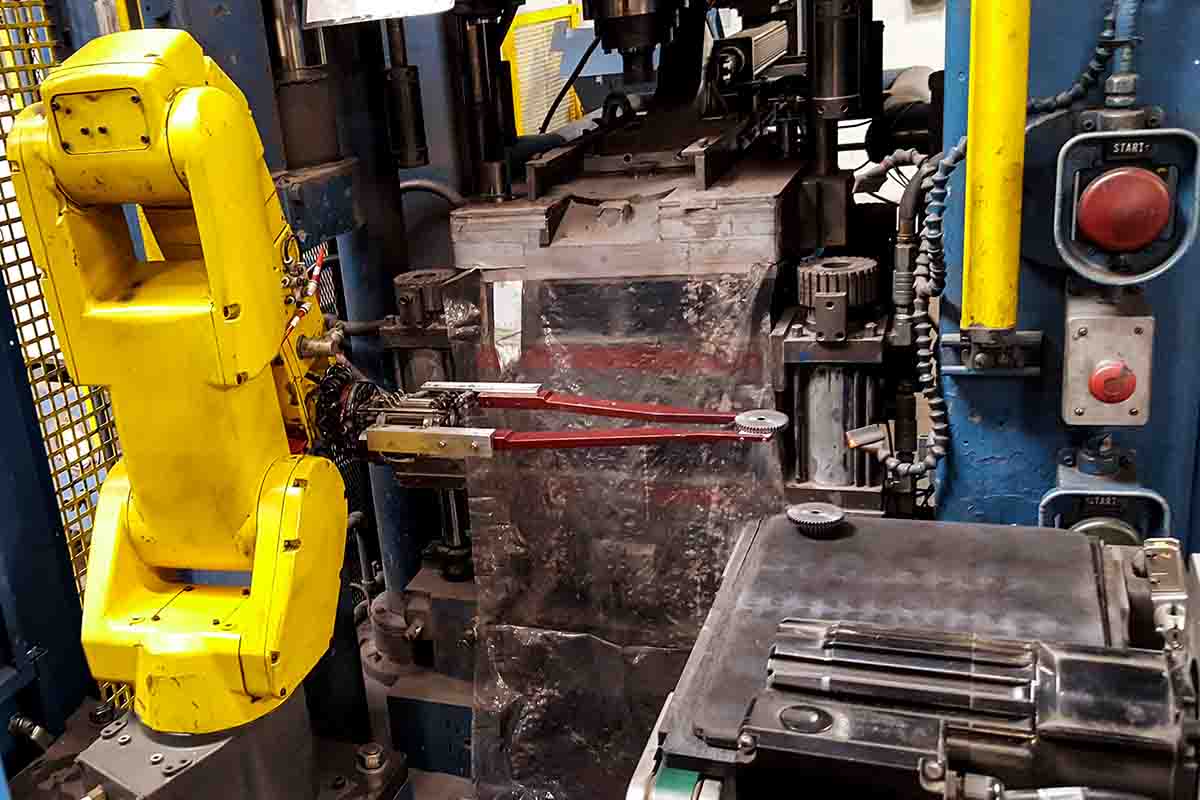

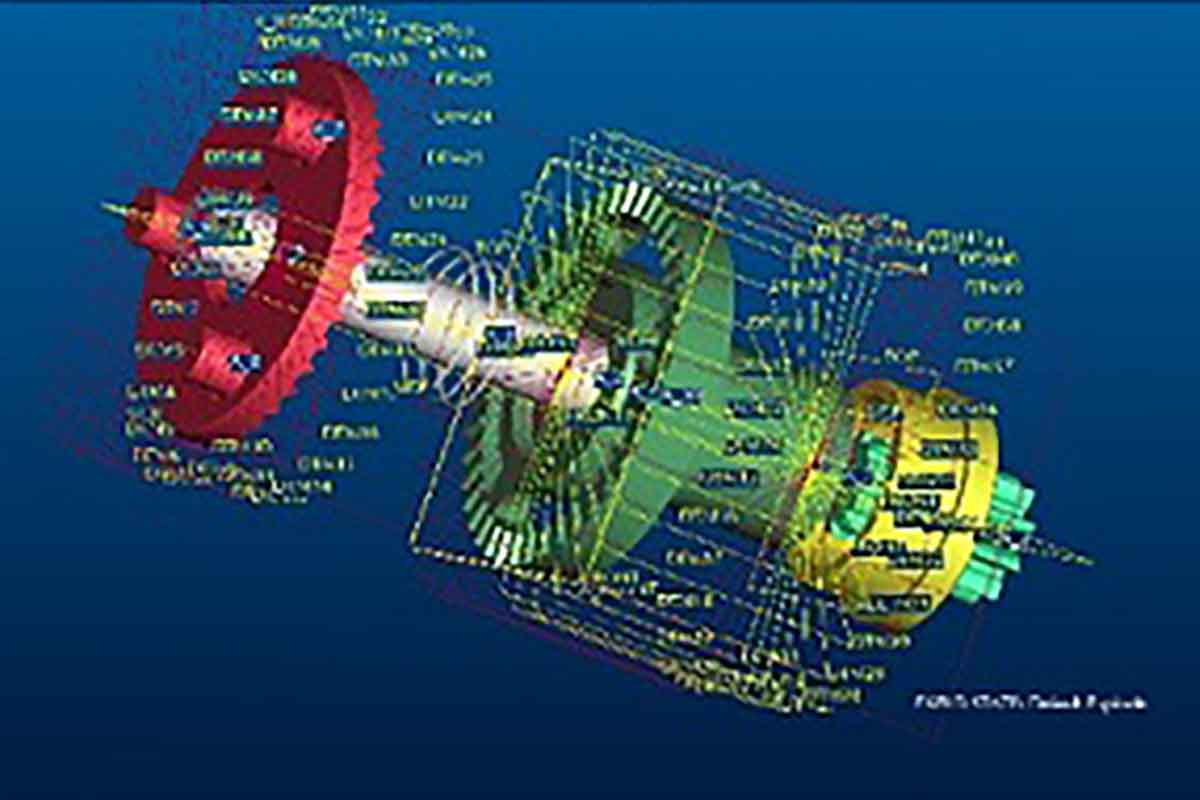

Continuous Belt Furnaces High Temperature Pusher Furnace Temper & Annealing Furnaces Coining, Plating, Machining A controlled amount of mixed powder is automatically gravity fed into a precision die mounted in a special mechanical or hydraulic press and compacted, usually at room temperature, to achieve the density requirement for the powder being pressed.