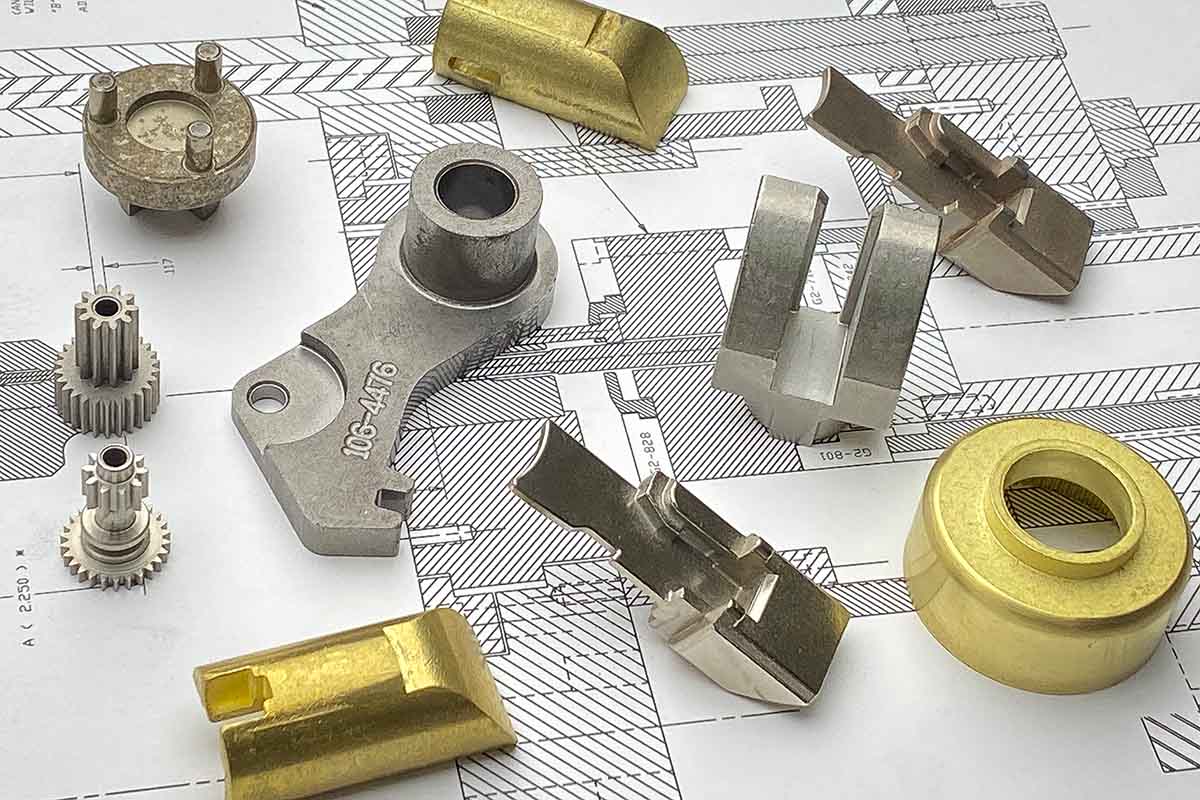

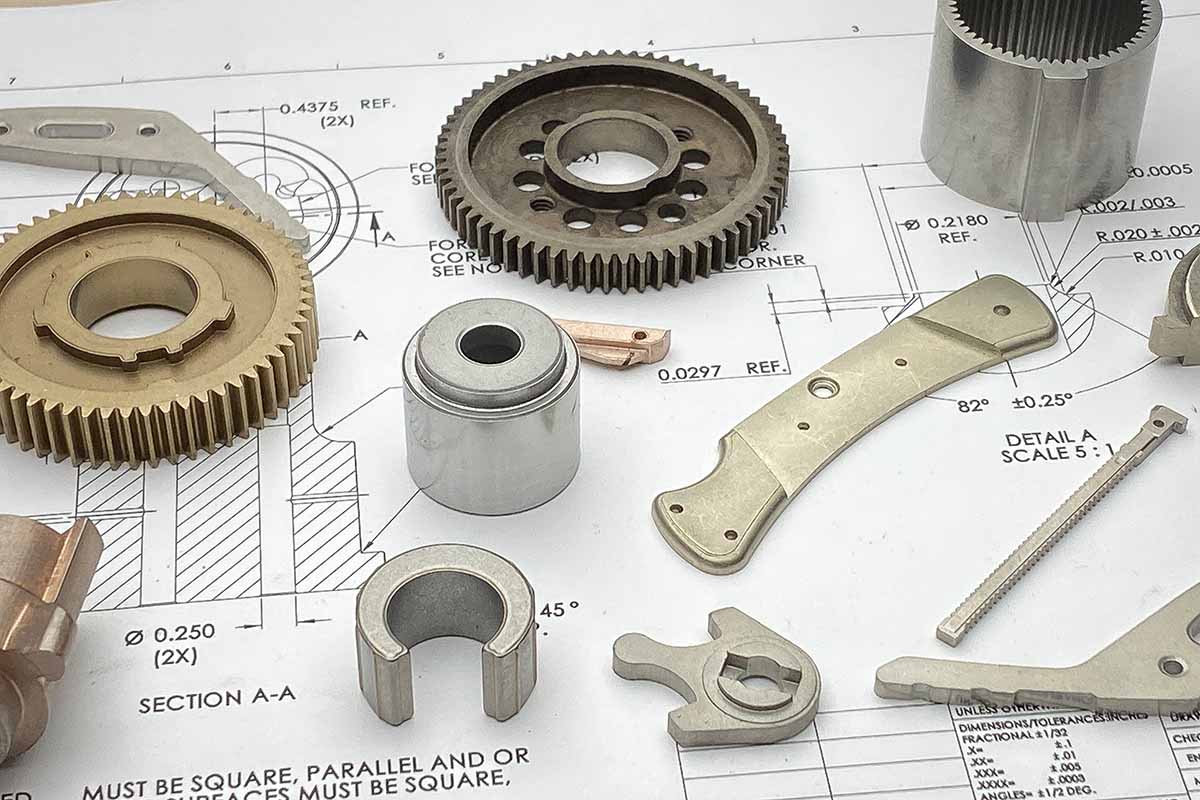

ASCO Sintering Co., one of the leading powdered metal manufacturers around the world, produces structural parts of superior mechanical properties. ASCO maintains precise process control, Six Sigma quality control methodology, and a closed-loop feedback system to produce high-quality powdered metal sintered parts and components.

parts are manufactured by compacting and forming from brass powder. Several studies reveal that the utmost stability of the chemical composition is found by sintered process from a homogenized brass powder.

Manufacturing Process

Sintered brass parts are rigid, high strength and heat resistant components manufactured through the process of sintering. Brass is one of the finest materials for the process of sintering because of its high corrosion resistance, machinability, and good deformability properties. The brass sintered parts manufacturing process involves following three basic steps.

- Transform into powder: The brass alloy is transformed into powdered form through the process of chemical decomposition, grinding, or centrifugal disintegration. In most cases, manufacturers use the popular atomization process to convert solid brass metal into powdered form.

- Forming: In this phase, the powdered metal is poured into a mold cavity or die to get the desired shaped parts. The mold or die needs to be sealed, vibrated and vacuumed.

- Compacting: Finally, the mold or die, containing brass metal, is placed into a hot isostatic press (operates at temperatures between 750°C and 1300°C) and compacted under great pressure in order to turn it into a solid shape. This particular step of this manufacturing process is called sintering. The outcome of sintering is a porous, strong, and solid metal piece.

Key Features:

Sintered brass parts are widely used in automotive, structural, and hydraulic industries. These sintered parts offer high and stable quality as well as high durability. Some of the key features of sintered brass parts include:

- High Strength: Brass parts manufactured through a sintering process with proper heat treatment offers high tensile strength and other superior mechanical properties.

- High Dimensional Accuracy: With an additional machining process, it can be achieved up to IT 5-7 dimensional accuracy depending on the geometry of the components.

- High Reliability and Repeatability: The parts with SPC control system offer high-reliability repeatability to the mass production.

- Self-Lubrication: The interconnected small pores of the PM parts can be filled with oil or other lubricants that work like a self-lubrication system in contact with the wearing surfaces. So, no additional external lubricant is required.

- Vibration damping: The structural micro-porosity of the sintered brass parts absorbs the effect of vibration.

Lightweight sintered brass parts

are typically 5% to 25% lighter than the similar size parts produced by the traditional manufacturing processes.