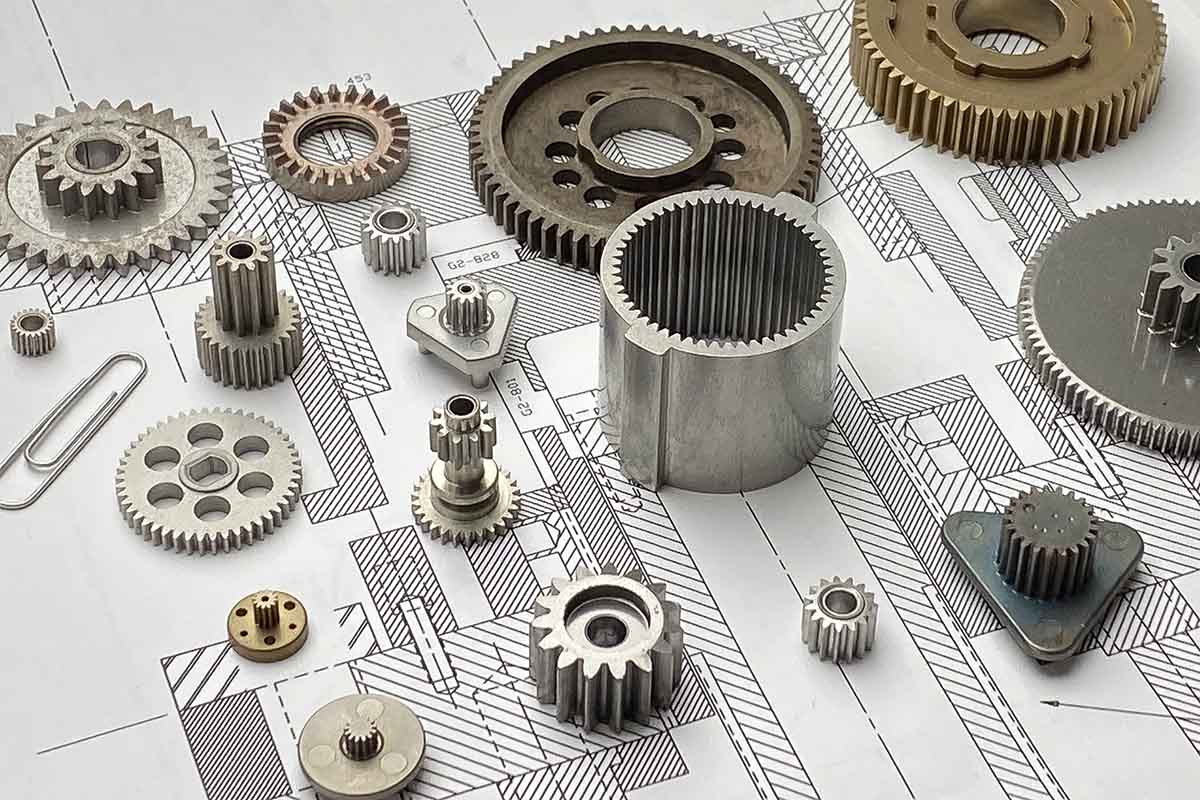

Conventional Powder Metallurgy (PM) Process

CONVENTIONAL PM PROCESS Also known as press-and-sinter, the process consists of mixing elemental or alloy powders with lubricants or additives to produce a homogeneous mixture. Additives may help improve machinability, wear resistance, or lubricity of the part; compacting the mixture in a die at pressures typically as low as 138 MPa (10 tsi) or as high