- 4 to 220 Tons Pressing capacity

- Fluidized Die cavity filling

- Real time Press Force monitoring

- Multi-Cavity Tool Designs

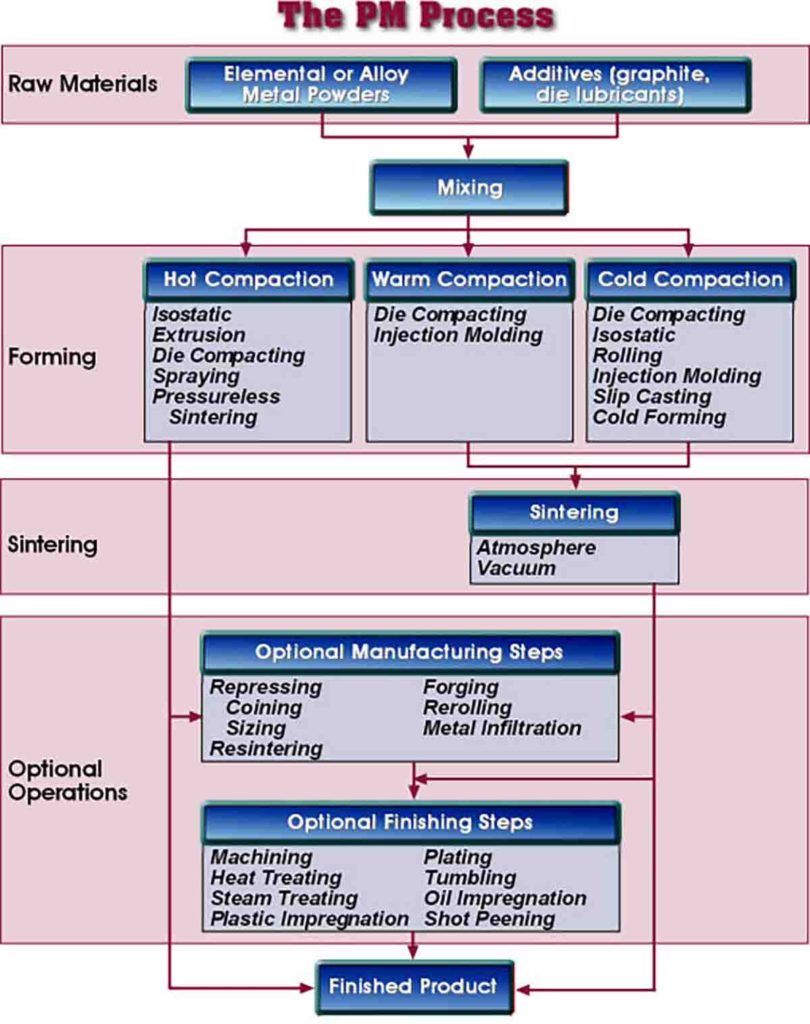

A controlled amount of mixed powder is automatically gravity fed into a precision die and is compacted. This is usually at room temperature, at pressures as low as 10 tons per sq. inch, or as high as 60 or more tons per sq. inch, (138 to 827 MPa) depending on the density requirements of the part and the powder being pressed. Compacting the loose powder produces a “green” compact that, with conventional pressing techniques, has the size and shape of the finished part when ejected from the die, and sufficient strength for in-process handling and transport to a sintering furnace. Typical compacting techniques use rigid dies set into special mechanical or hydraulic presses, Tool sets are made of either hardened steel and/or carbides, and consist at least of a die body or mold, an upper and lower punch and, in some cases, one or more core rods.