Hi-Impac, a P/M (Powdered Metal) material and process that produces powder metal parts with significantly better properties than those obtained with conventional high strength P/M.

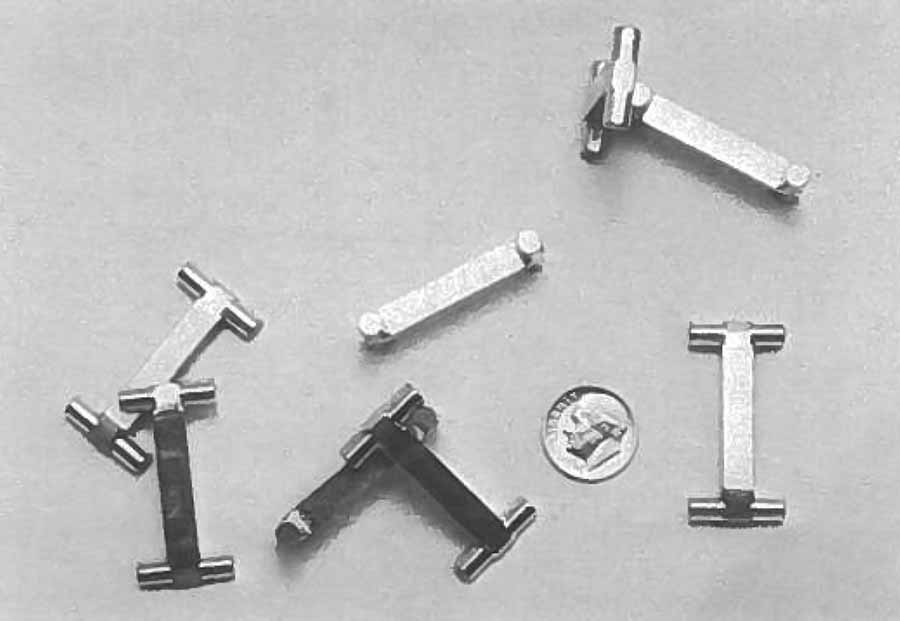

The part shown above was originally made from P/M infiltrated steel (FX- 2008-n When tensile tested by gripping the ends and pulling in the opposite directions, as shown in the diagram, failure occurred at an average of 800 Ibs. After changing the material to Hi-Impac, failure under the same test conditions occurred at 1500 Ibs.

The improved properties, such as tensile strength, elongation and impact strength, are the result of a combination of new materials and processing technologies.

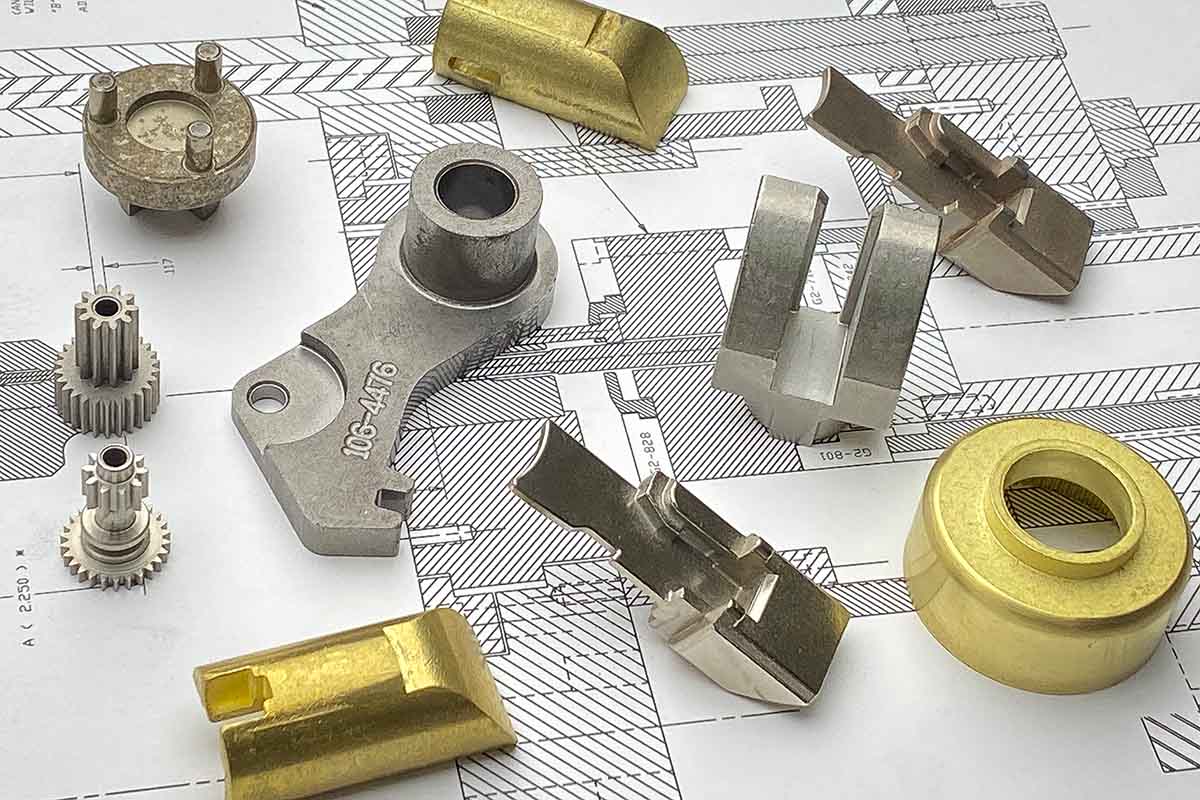

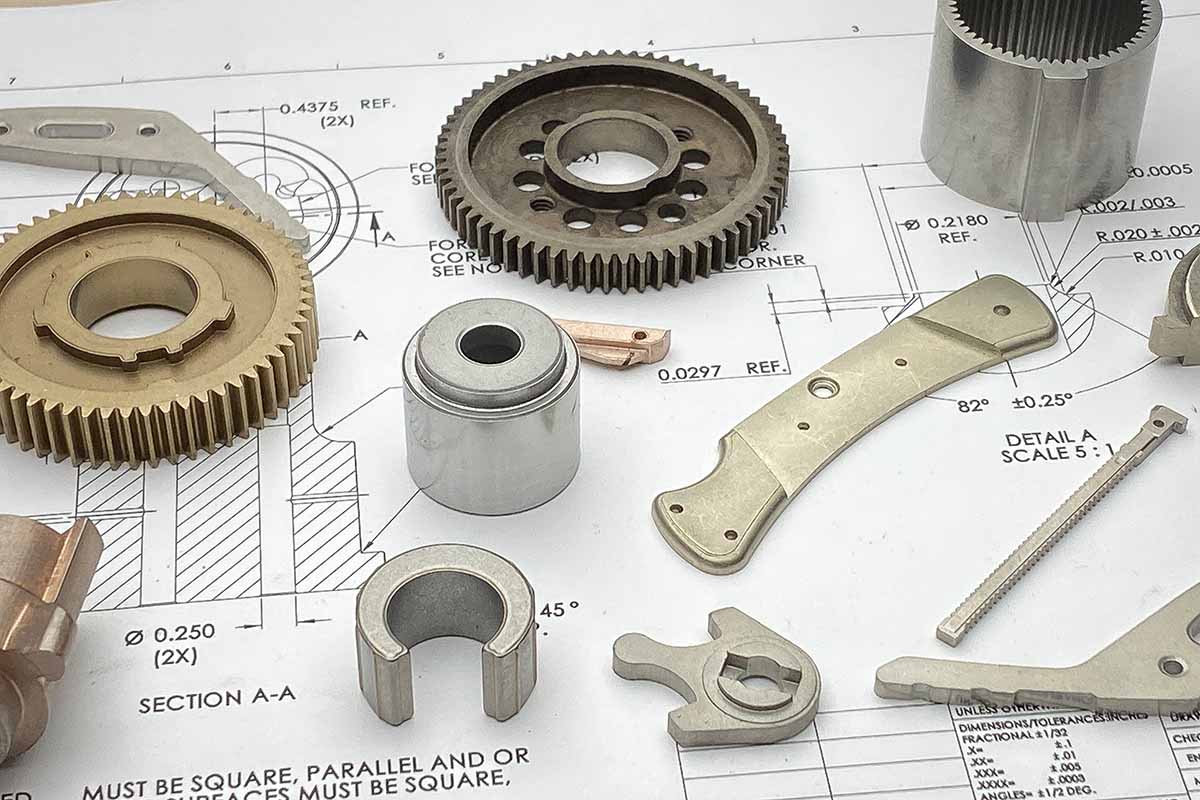

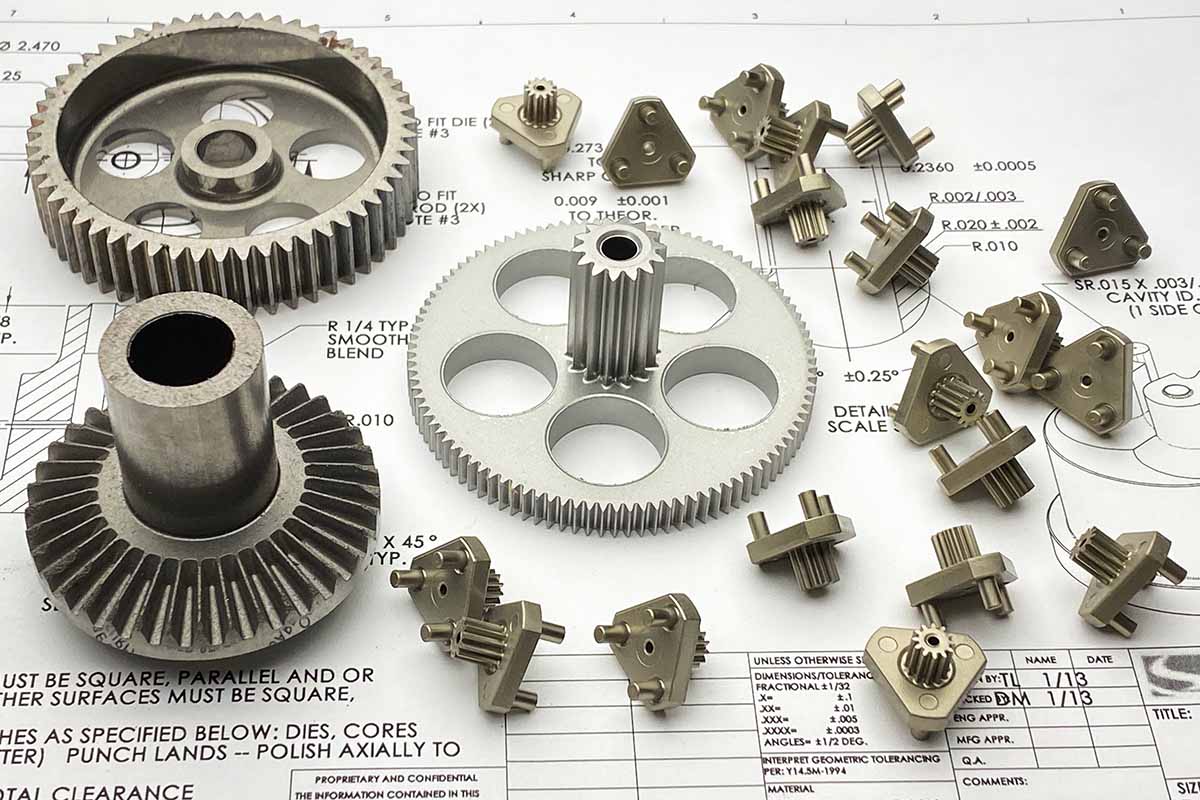

Hi-Impac P/M will produce parts with greater density, increased strength, toughness, hardness and thermal conductivity. It is ideal for parts requiring shock resistance, such as gun parts, gears, lock parts, cams, ratchets, pawls and levers.

If you have parts requiring properties greater than those available with conventional P/M, perhaps Hi-Impac can help you.