Diverse range of industries are using Hydraulic quick couplings, including construction, agriculture, food and chemical processing, forestry, etc. These hydraulic couplings are specially designed for high-pressure hydraulic operations to reduce pressure drop across the hydraulic connection. It provides the most convenient way to continuously connect and disconnect hydraulic fluid lines. The couplings also ensure that there are no hydraulic fluid spills or entrance of outside air into the system.

Working Principle of Hydraulic Quick Coupler

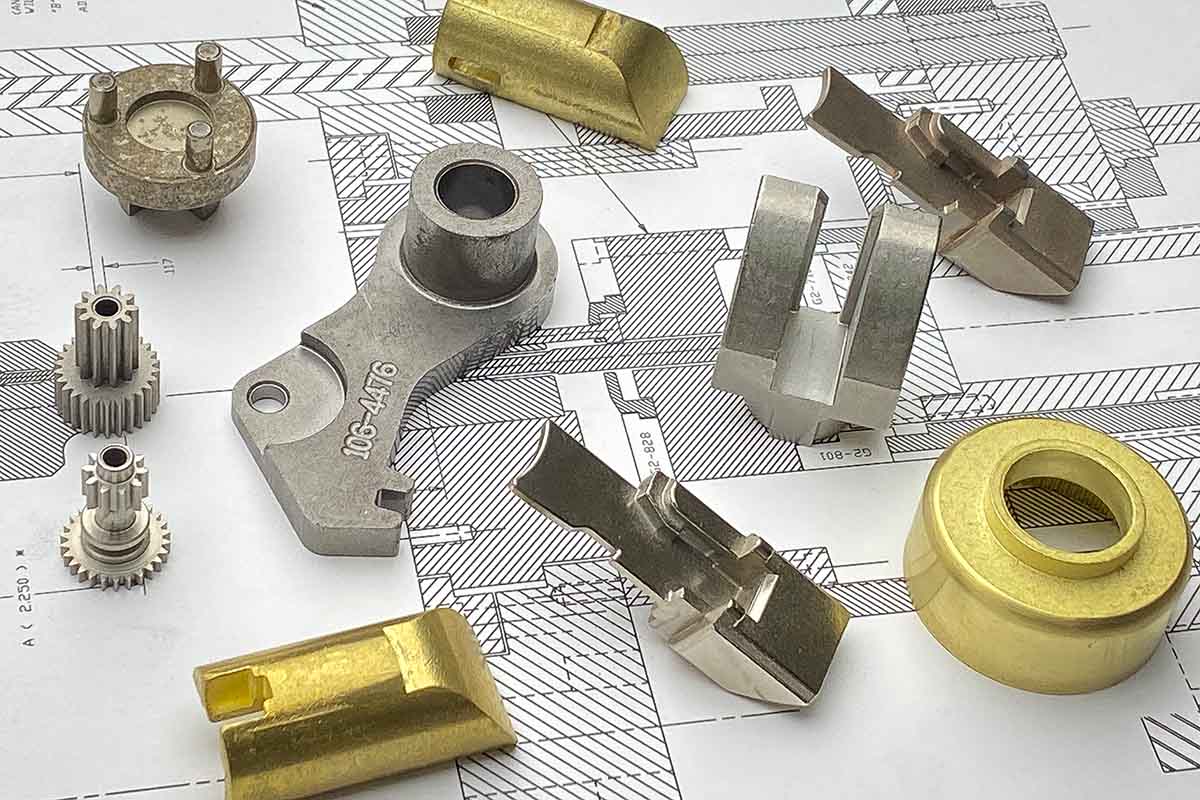

The hydraulic quick coupler consists of a joint body, a jacket, a check valve core, a number of steel balls, a spring, and a seal. The check valve is located in the inner cavity of the joint body. As soon as the joint body is detached, the reel of the check valve extends out under the action of their corresponding springs. It also creates pressure opposed to the tapered hole of the joint body to close the flow. So, the fluid in the passage is sealed and cannot flow out. On the other hand, when the joint body is connected, the two ejector rods at the front end of the check valve core come together and force the valve core to take off from the angular hole of the joint body. So, at that time, the fluid in the passages can flow.

The joint body is secured with steel balls. While working, the jacket forces the steel balls into the U-shaped groove to close the joint body. The tight seal helps to maximize the productivity of the hydraulic system and prevent fluid spills.

Benefits of Using Hydraulic Quick Coupler

- Allows fluid lines to be easily and quickly connected and disconnected without the need for additional tools.

- Allows effective flow of the fluid without any spills and maintains stable system performance.

- Promotes workplace safety by eliminating the risks associated with hydraulic system leakage.

Applications

- Industrial hydraulic lines

- Water and coolant lines

- Food and chemical processing units

- Gas pipelines

- Hydraulic presses

- Agricultural equipment

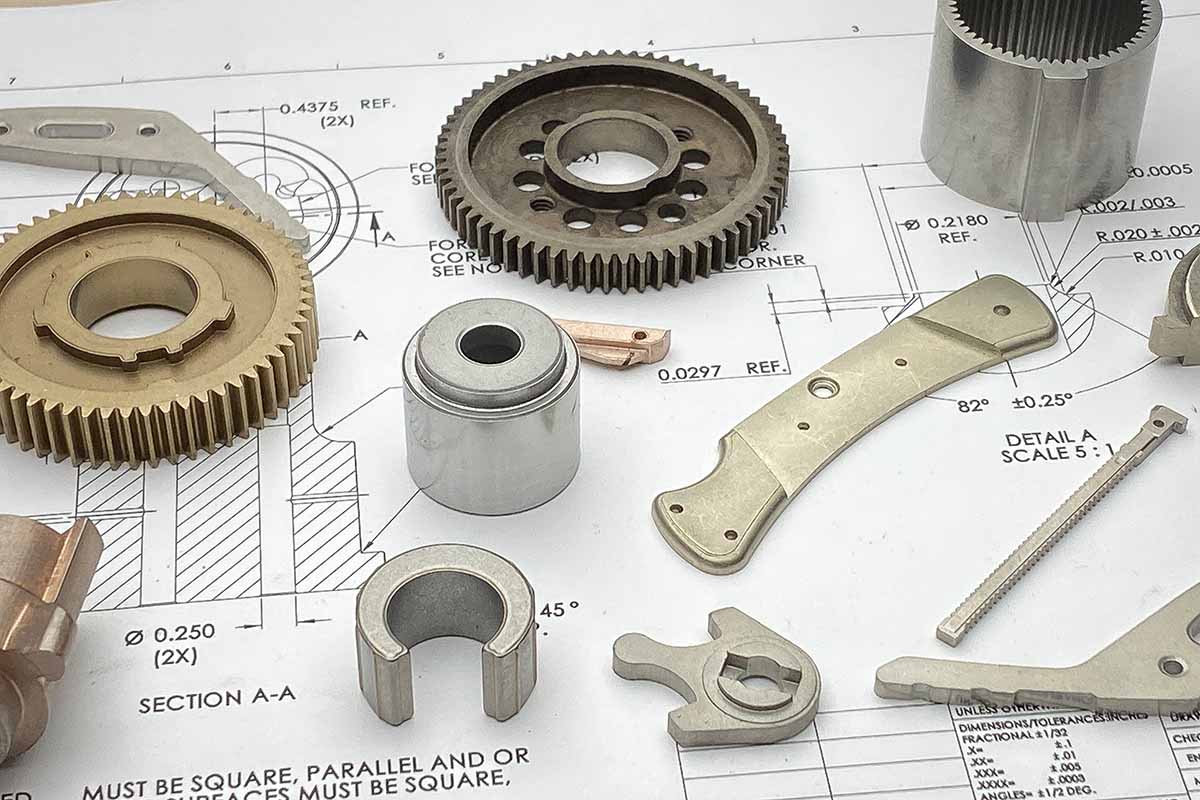

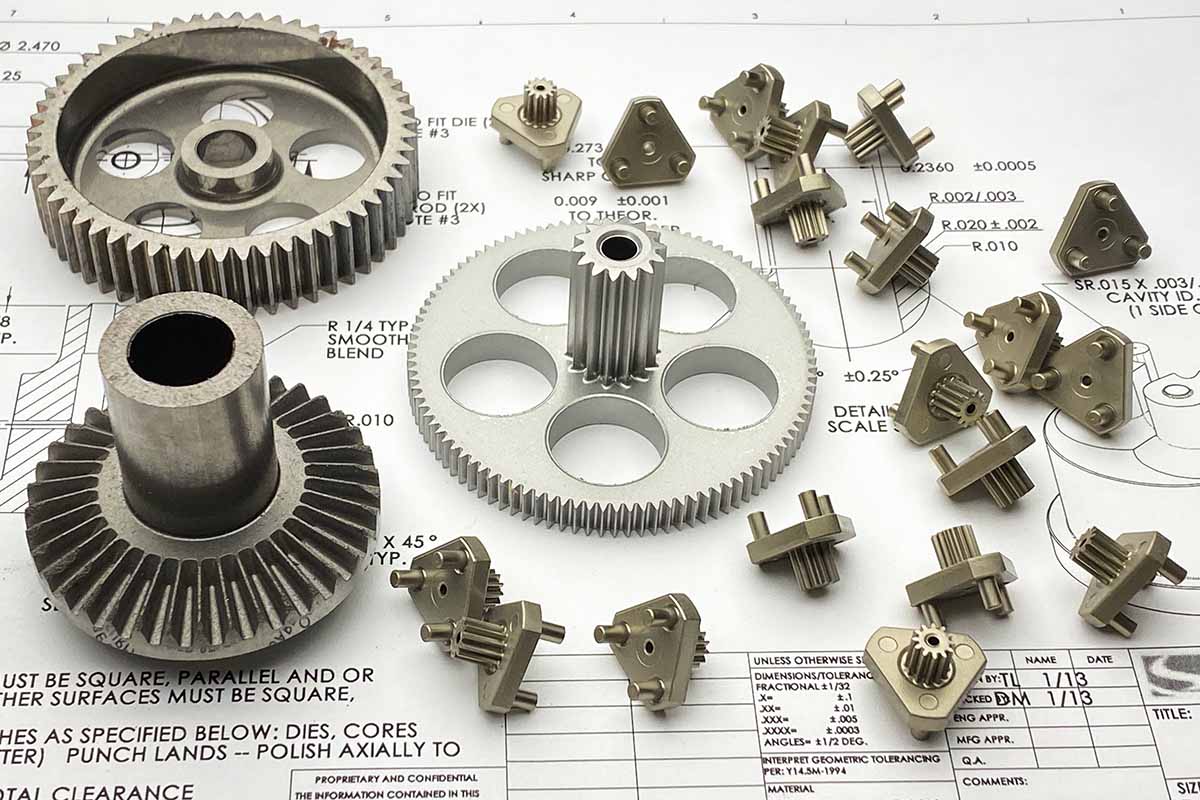

ASCO Sintering Co. a part manufacturer of hydraulic quick couplers for one of the market leaders for providing high-quality leak-proof and durable hydraulic quick couplers. The company produces parts for a wide selection of hydraulic quick couplers to fit versatile fluid applications.

The types of hydraulic quick couplers:

- Ball-lock hydraulic coupler

- Roller-lock hydraulic coupler

- Pin-lock hydraulic coupler

- Flat-faced hydraulic coupler

- Ring-lock hydraulic coupler

- Cam-lock hydraulic coupler

To manufacture parts for hydraulic quick coupler ASCO uses highly engineered materials such as HI-IMPAC