ASCO Sintering Co. is one of the renowned powdered metal manufacturers that produce high precision medical component sintered parts used in diagnostics, treatment, and surgical procedures. ASCO uses highly engineered modern sinter-hardening materials to manufacture osteoporosis pen ratchets, flow control spring seats, surgical stapler planetary gear system, and so on.

The components used in the medical industry must be human-body-compatible, sterilizable, non-corrosive, and durable. Sometimes, the parts are extremely small with very limited process variations. With traditional manufacturing processes, it can be difficult to produce such miniature parts within the close tolerance limits require to make sure the error-free functionality of medical equipment.

Powdered metal manufacturing (PM) is one of the perfect substitutions for making high-precision components used in medical equipment. The advantages and technological innovations gained from using powdered metal manufacturing are as follows.

- Volumes: PM sintering process is a leading technology adaptable to produce very small and complex precision parts in medium and high volumes.

- Tolerances: By using powdered metal manufacturing techniques, it is also possible to achieve some of the most demanding OEM tolerances by minimizing the process variations.

- Faster manufacturing: Powdered metal parts are net shape or near-net shape that rarely require any secondary machining process. So, this technology can save extra time and money by decreasing multiprocessing.

- Low wastages: Powdered metal sintering process reduce the risk of parts failure, hence lowering the rejection percentage and resulting in low wastages.

- Complex parts: Powdered metallurgy methods can manufacture very small and complex design parts with minimum tolerances that cannot be possible by other manufacturing methods.

- Superior surface finish: Parts manufactured by the PM method have superior surface finish (roughness of a surface down to 32 μm).

- Biocompatibility: There is a number of biocompatible medical-grade powdered materials are available for use.

Medical Component Sintered Parts Manufactured by ASCO

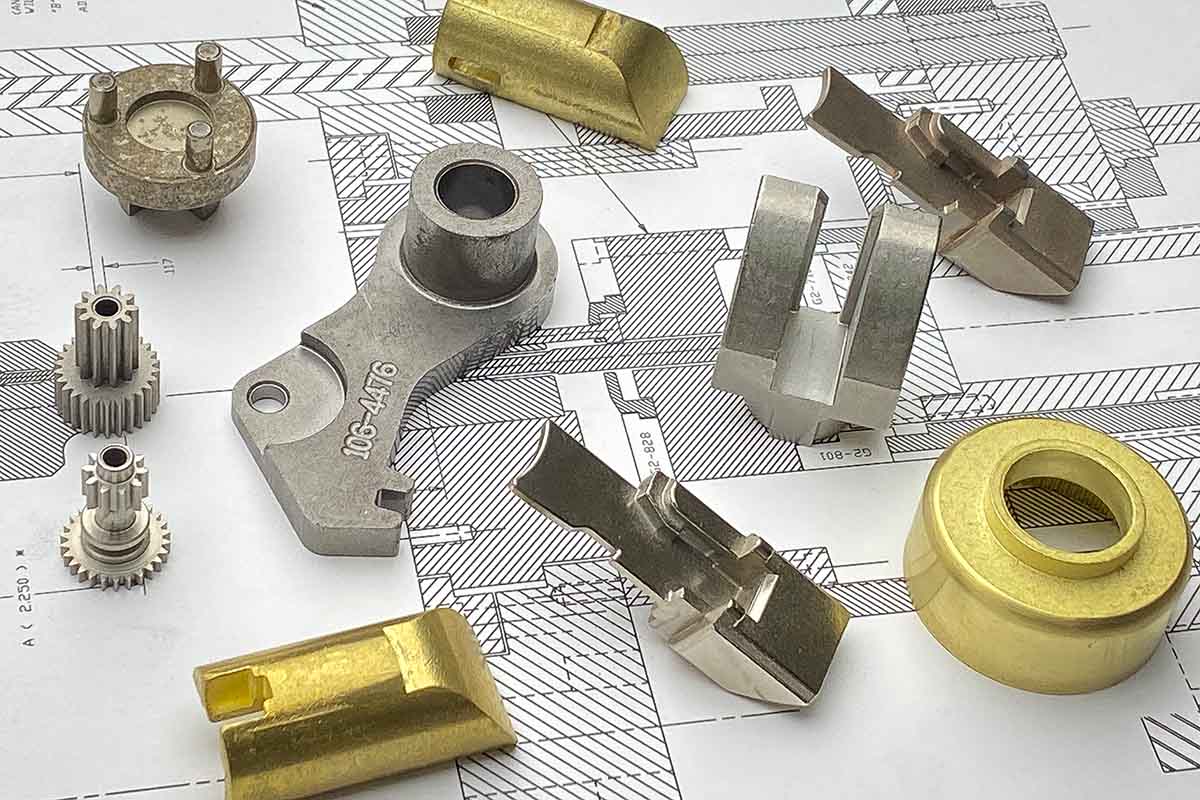

ASCO Sintering uses the combination of unique engineering design, automation, and expertise to manufacture a wide range of critical components used in medical equipment and devices.

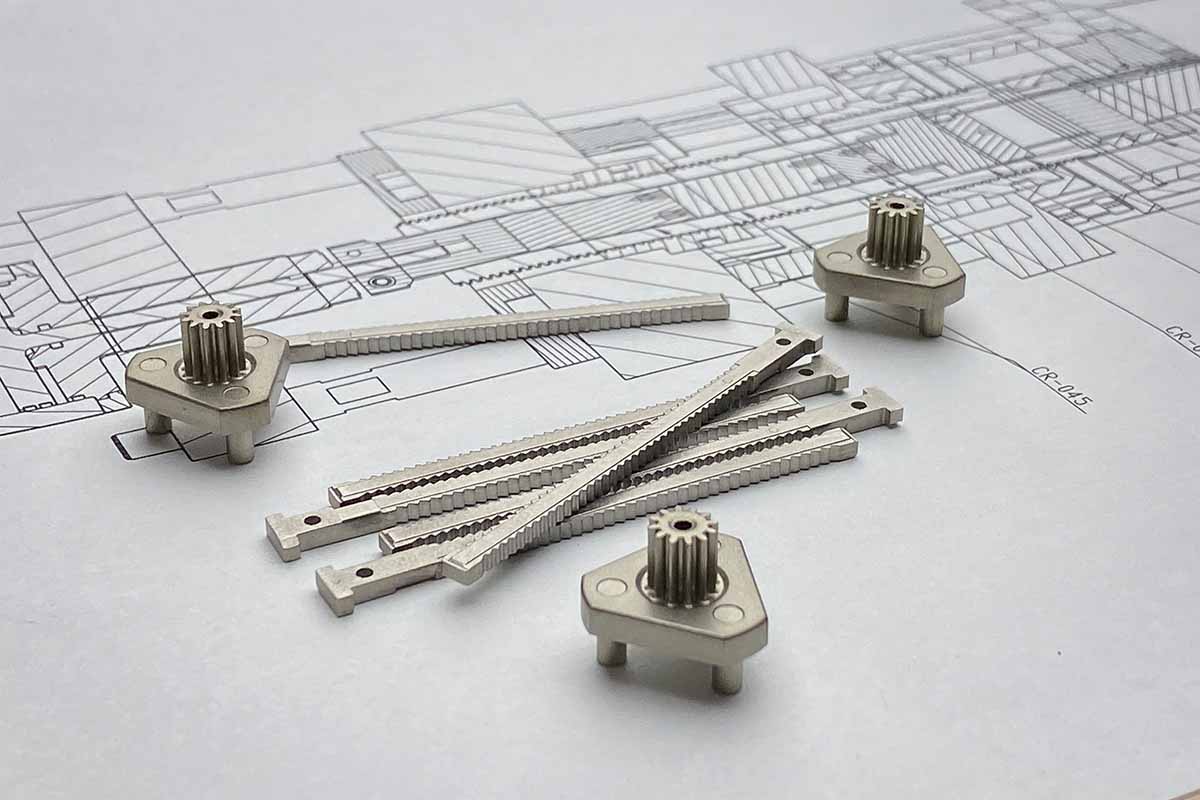

Osteoporosis Pen Ratchet: ASCO produces high precision sophisticated stainless steel pen ratchets used in drug delivery systems. Every tooth of the ratchet indicates a specific dose of a prescription osteoporosis medication.

Flow Control Spring Seat: This PM sintered stainless steel spring seat operates as a pressure limit valve and widely used in the kidney dialysis machine. It facilitates a preset pressure by adjusting the seat against the spring on the threaded shaft.

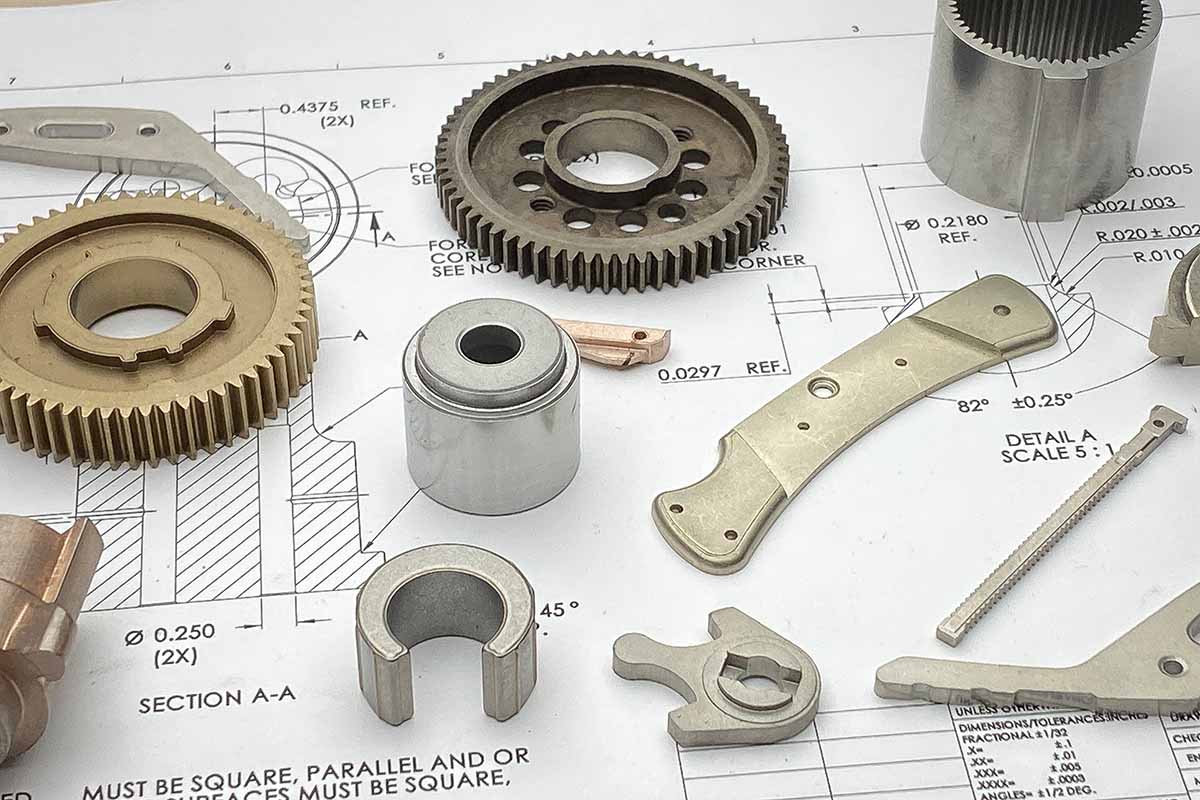

Surgical Stapler Planetary Gear System: A sinter-hardened surgical grade stainless steel planetary gear system used in physician-operated portable surgical devices. This planetary gear system is an excellent example of sintered metal medical application.