These days’ medical device parts are more patient-centric and customized than ever before. Only highly engineered and precision parts can ensure high-quality end devices for critical medical applications. That’s why medical device parts are one of the most challenging components to manufacture.

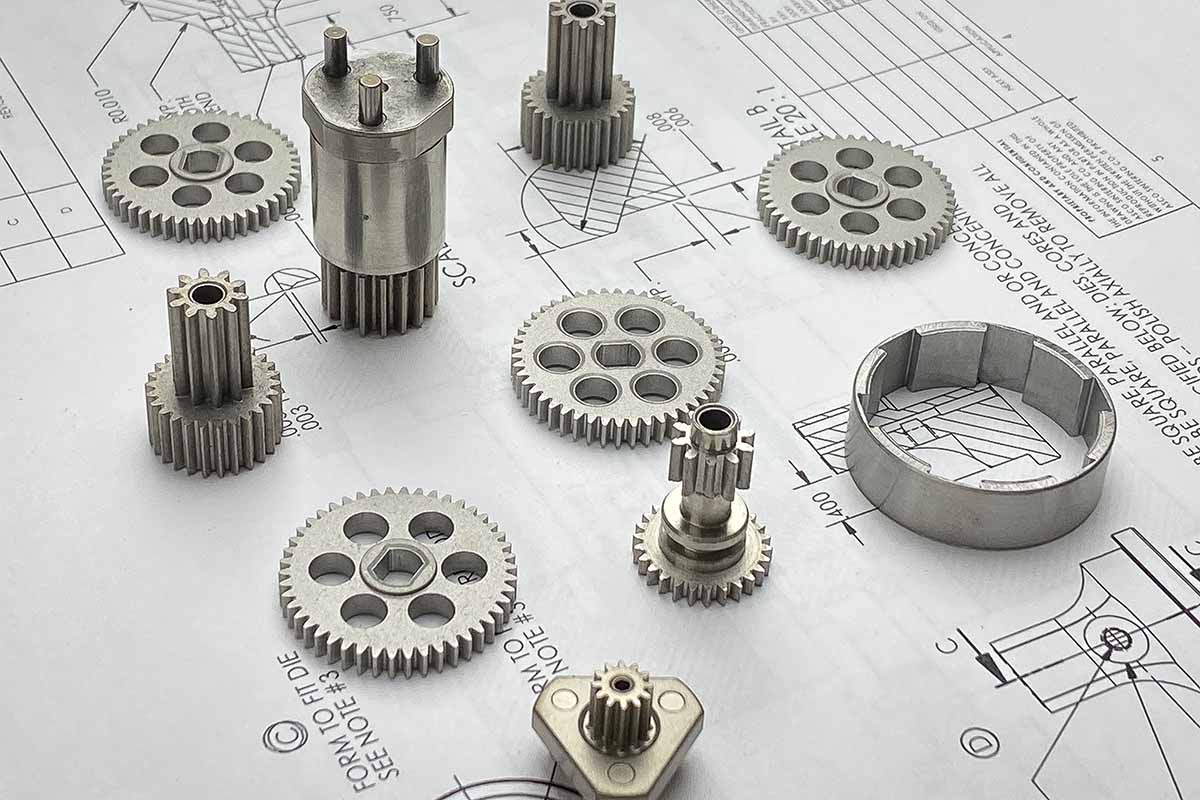

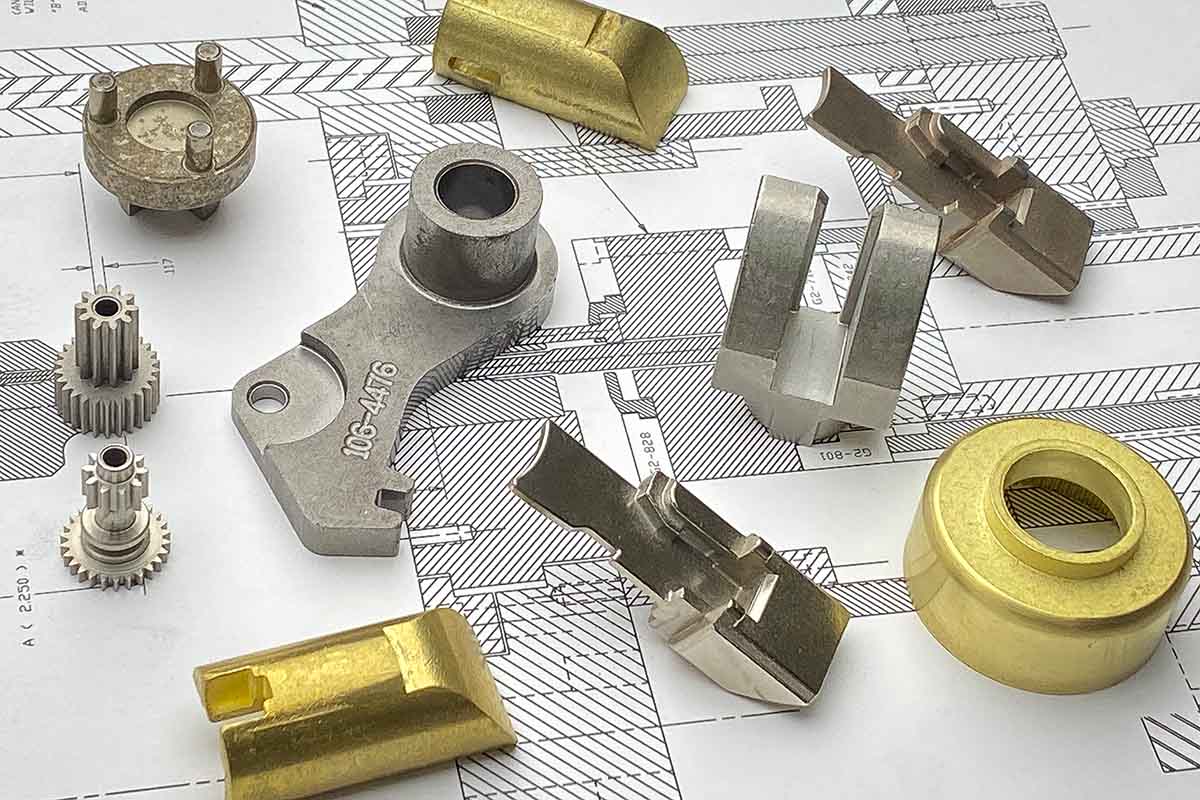

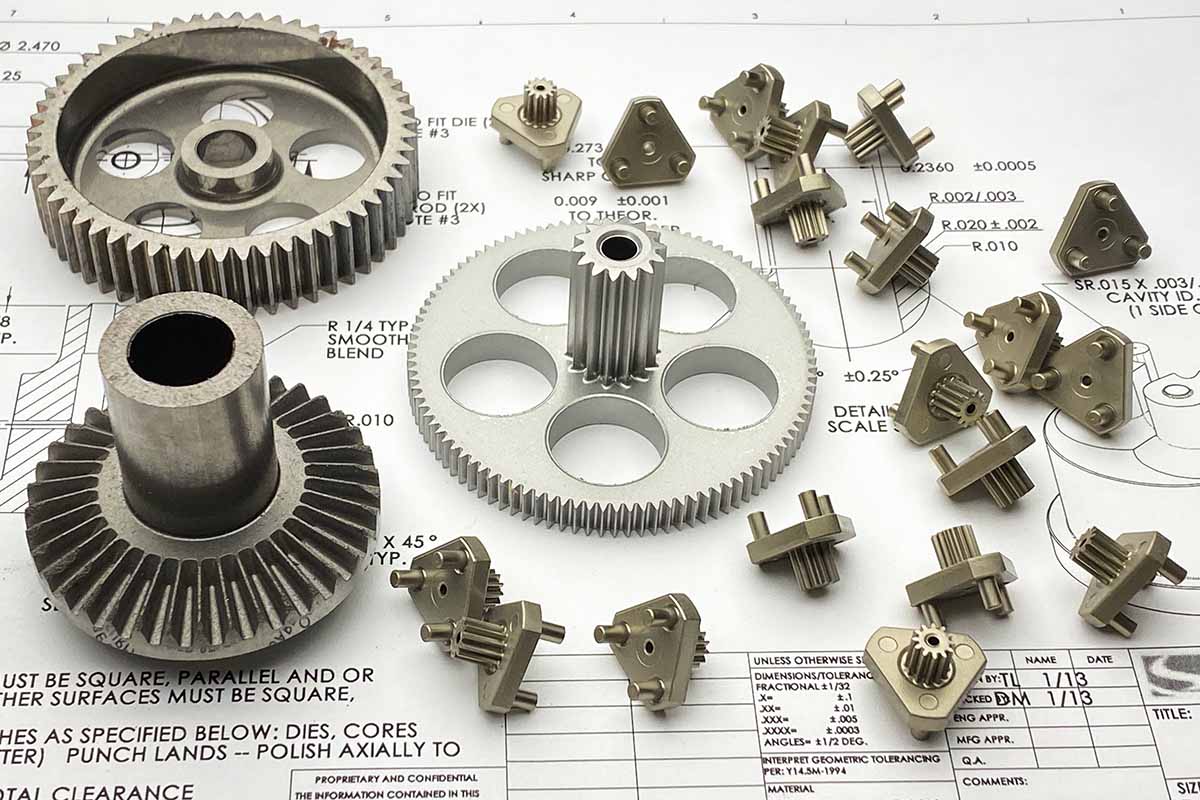

ASCO Sintering Co., a leading U.S.-based precision engineered metal components manufacturer, specialists in the development and manufacturing of implantable medical device parts. ASCO offers customized solutions for a wide range of medical applications that meet today’s strict industry needs. We use high-quality machinery and equipment to ensure top-quality end parts for critical medical applications. While manufacturing typical medical device parts, we ensure:

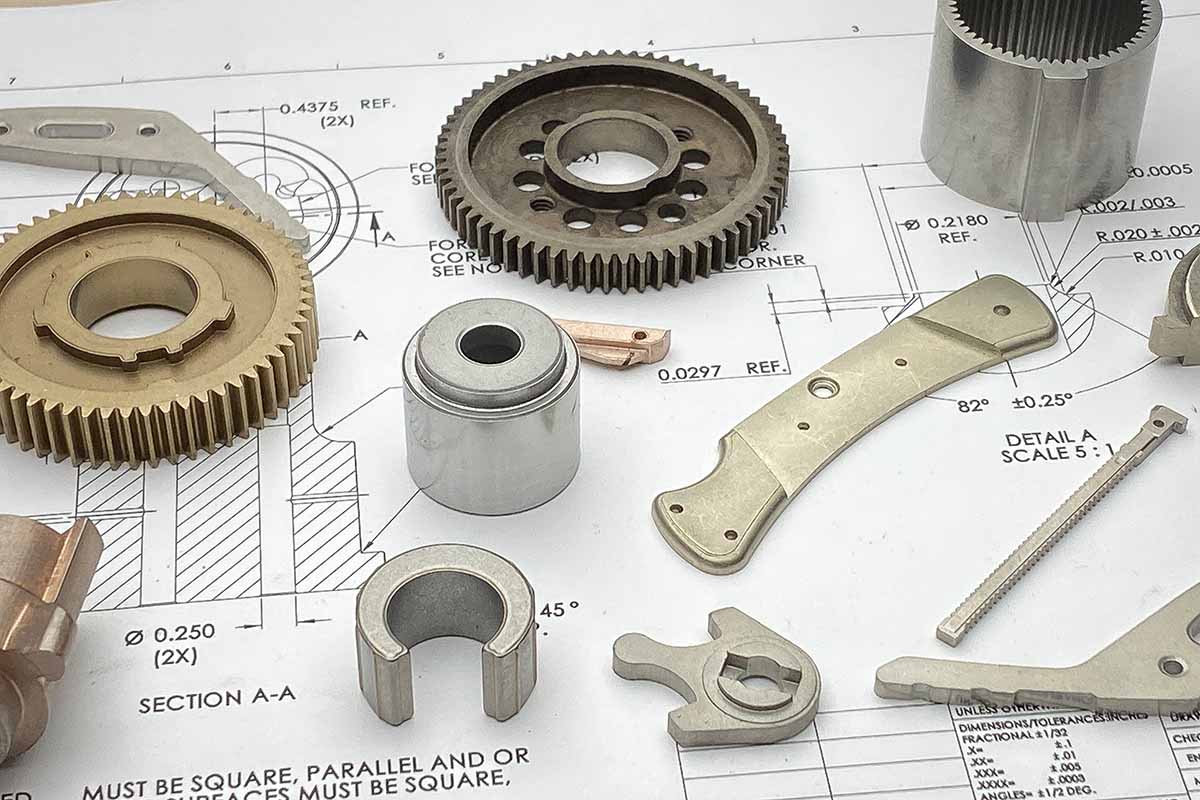

- Use a variety of materials for manufacturing all the parts

- Working with cutting-edge precision equipment

- Ensure durability and high-quality surface finish

Commitment to Quality

ASCO Sintering Co. is committed to providing high-quality and precision medical device parts. All produced parts pass through an automated inspection system with a micro-precision magnification level. We are open to customizing the inspection and sampling plan depending on the needs of the product and customer requirements.

We can provide material blanks made of powder metal and sintered in house for rapid prototype technology to test designs, components, and features under real conditions. It ensures added safety and gears up the new product lunch. To ensure optimally hygienic, safe, and highly functional medical device parts, we focus on automating as much as individual stages as possible in the component assembly process.

All the team members of ASCO actively participate in our continuous improvement process by maintaining TQM guidelines. From inspection of raw materials to manufacturing, all in-process and end-process, quality is assured.

Achieving Excellence in Manufacturing

Medical device parts are highly customizable and it needs rapid fixing and continuous improvement. To develop a critical medical device part it is important to minimize the gap between the user’s needs and the designer’s perception. So, a strong design team is vital here. To achieve expected quality and business growth in medical components manufacturing, an organization must achieve a state of operational excellence. So that everyone in the organization knows their participation in the process flow and can able to implement the standard methodology for fixing the processes when it goes wrong.

At ASCO, we always start with the client’s problem and end with finding out an effective solution. ASCO has a completely in-house R&D and exclusive manufacturing facility to identify the optimum, cost-effective, and most reliable process from prototype to bulk production. Our highly experienced engineering and manufacturing team is very much collaborative to manufacture 100% custom medical device components.