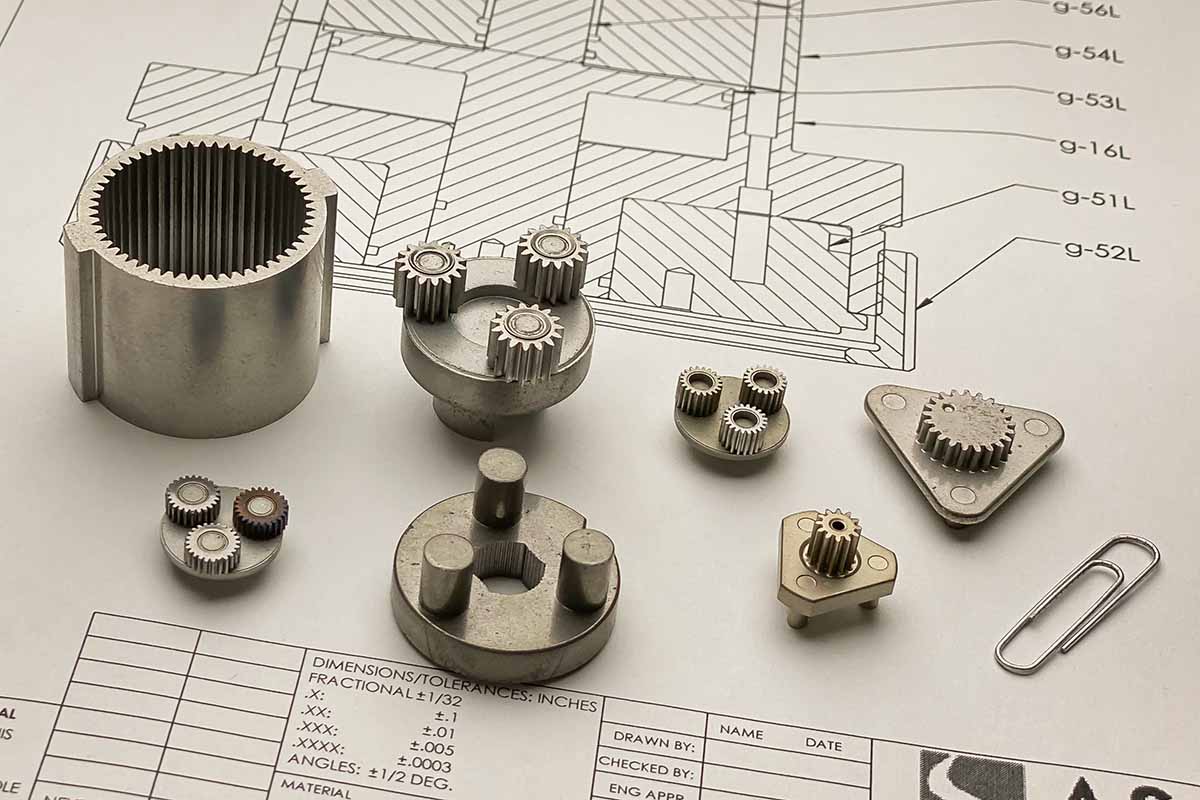

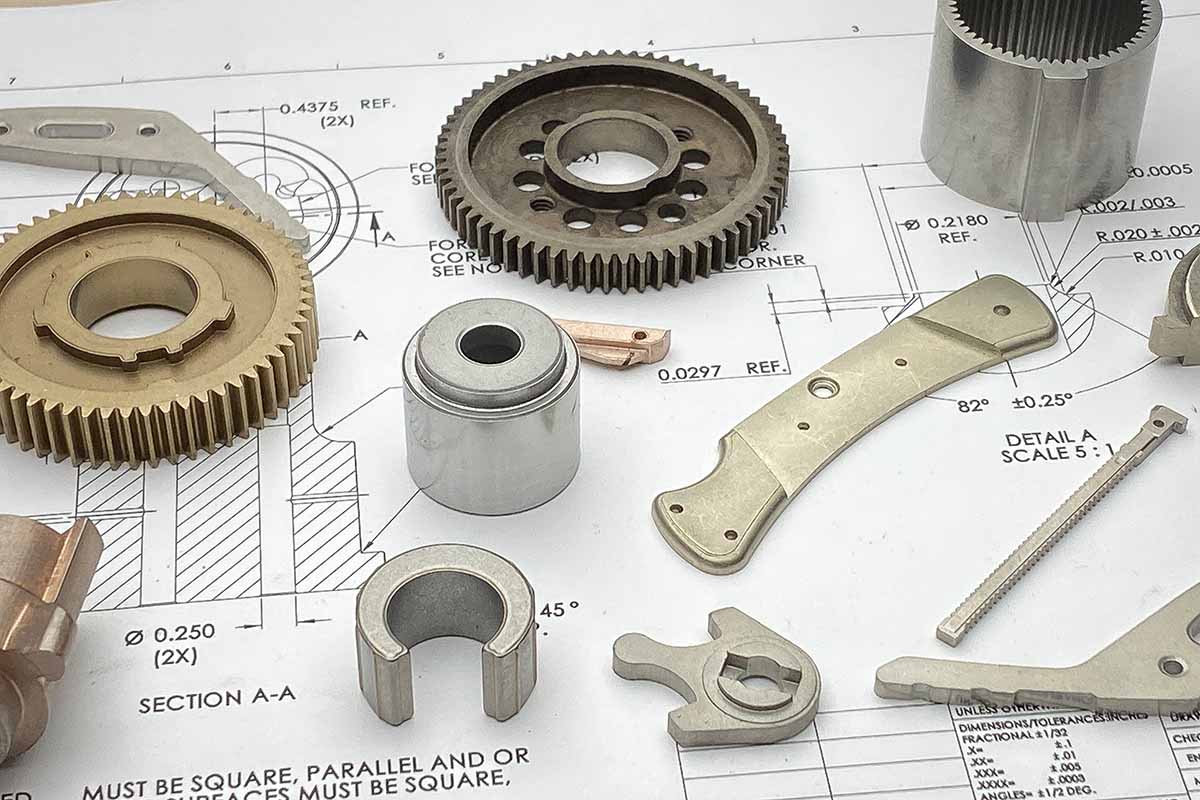

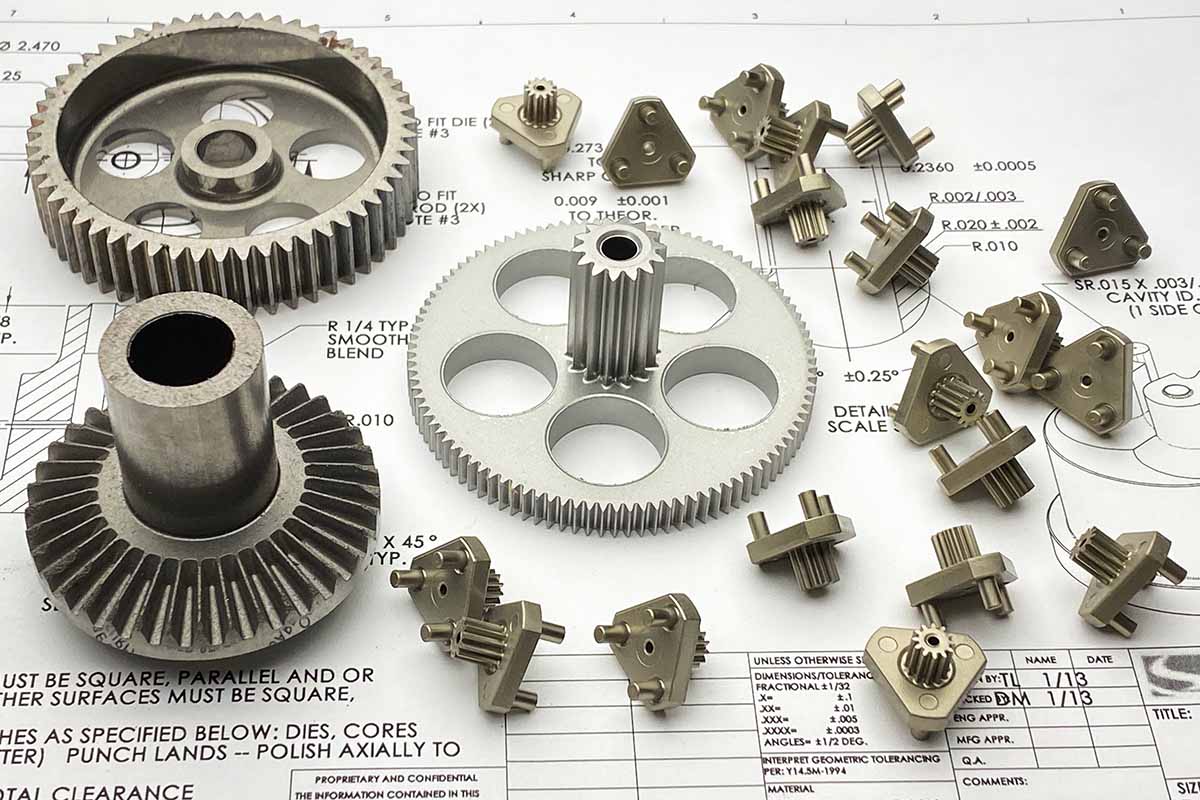

The planetary gear is a type of gearing system to lower the speed of a rotating shaft. A planetary gear system consists of three main components: a sun gear, several planet gears, and a ring gear. The position of the sun gear is in the middle of the gearing system. The planet gears are distributed evenly around the sun gear and interlocked with an outer ring gear. Usually, the input shaft connects the central sun gear. Surrounding it, the planet gears revolve enclosed by an outside ring gear and are messed to the output shaft through a carrier. The design of the planetary gear system can vary depending on the motion requirement and application.

Applications of Planetary Gear Systems

The planetary gear system has a wide selection of applications including automotive, marine, industrial machinery, construction equipment, turbine engines, pumps, drills, and others.

Usually, planetary gears are speed reducers. Therefore, it can minimize the motor’s rpm and increase the torque. The gearing system can also provide high transmission ratios with convenient mass inertia ratio conversion. That’s why all automatic transmission systems contain several planetary gear sets that require a firm power shifting mechanism. The compact and robust design of the latest planetary gear system makes it possible to use it in electric screwdrivers, mixers and blenders, hoist drives, and robotics.

Advantages of Using Planetary Gear Systems

The planetary gear systems are very popular as a power transmission solution. It has lots of benefits in contrast to conventional gearboxes. The advantages include:

- Are versatile, robust, and rugged

- Provide a wide range of speed to power ratios in compact space

- Have lower inertia and high torque transmission

- Provide high efficiency (around 97% of the power input is convertible into output)

- Suitable for a wide range of industrial applications

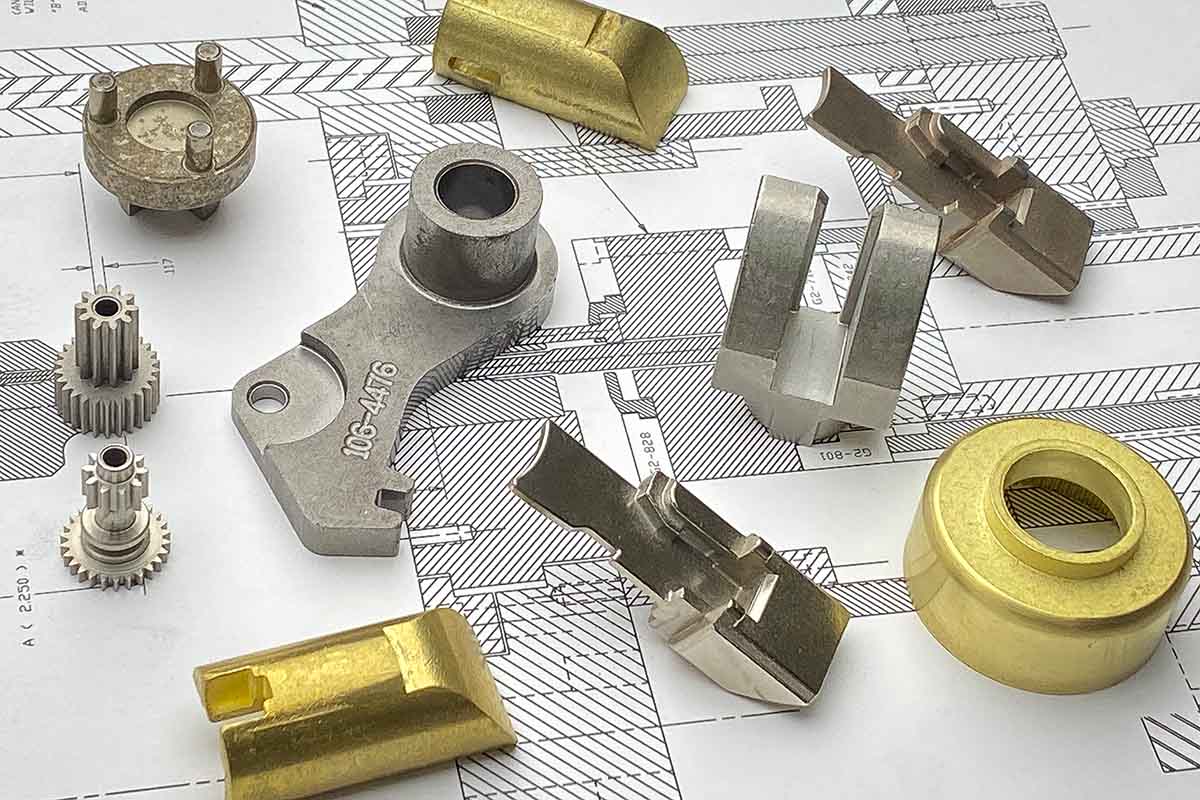

ASCO sintering is an industry leader specializing in the design and manufacture of sintered planetary gear systems and different powdered metal gear assemblies since 1946. We provide planetary gear systems that are highly customizable and are available in different sizes, reduction ratios, torque ratings, input speeds, and angle arrangements. They are also available with a variety of mountings, mechanical preloads, and housing options. The gearboxes have high power transmission capabilities with very little energy wastages. The average efficiencies can be achieved between 96% and 98%.

ASCO’s planetary gear sets are highly durable and good fit for heavy-duty applications. We have entire in-house engineering and manufacturing facilities to produce high-quality and high-precision planetary gear systems. Our planetary gear sets meet ODM, OEM, ISO, and other international standards.