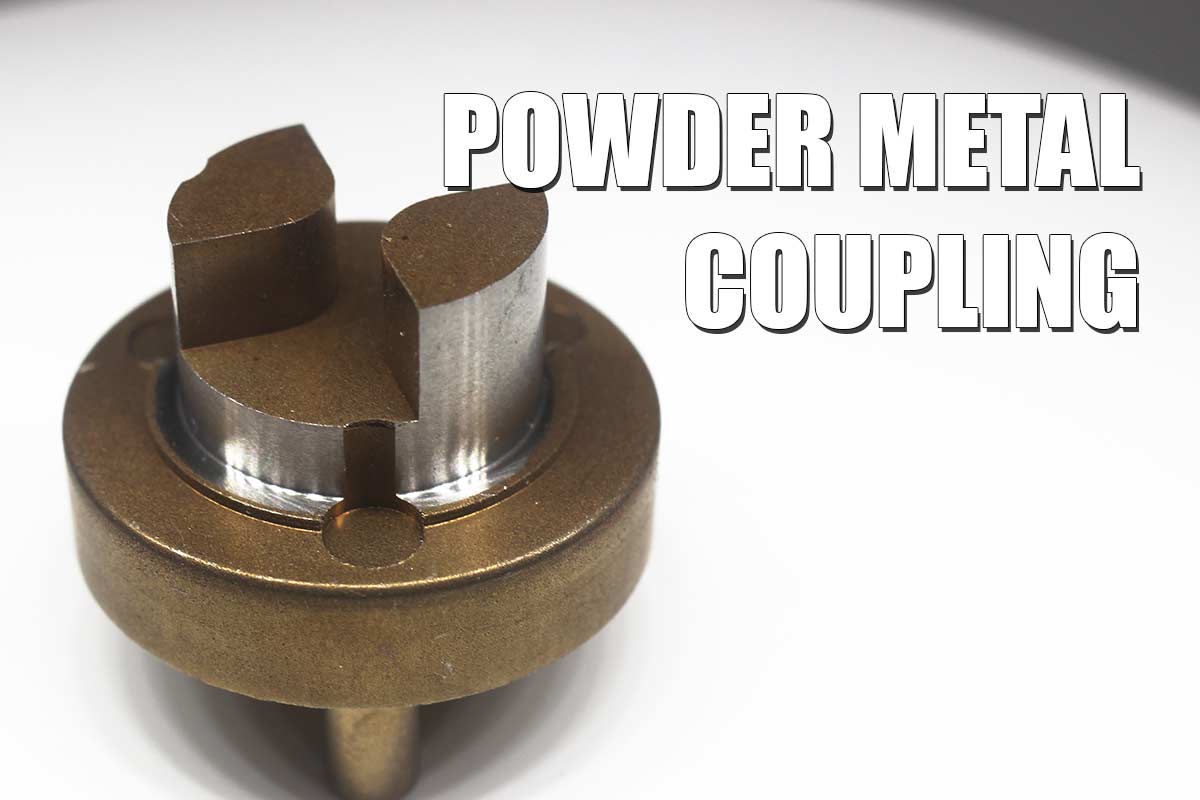

From one simple misalignment problem in an industry, the research started which leads to a brilliant solution of manufacturing powder metal couplings. Over the years, this problem brought a revolutionary change in the field of mechanical engineering. Now, in present era metal couplings are used to connect two shafts together at their ends in order to transmit power. The primary purpose of coupling is to control the alignment of the attached components in a torsionally rigid way. It can also permit some misalignment if it is required. Misalignment can be of three types that are angular, parallel or skew. The velocity or acceleration of the shaft could alter due to the misalignment.

Other most common uses of Powder Metal coupling are:

- To modify the vibration characteristics of rotating bodies

- To attach the driving and the driven part

- To bring in protection between connected parts

- To overcome the transmission of shock loads from one shaft to another

- To slip when there is an overload

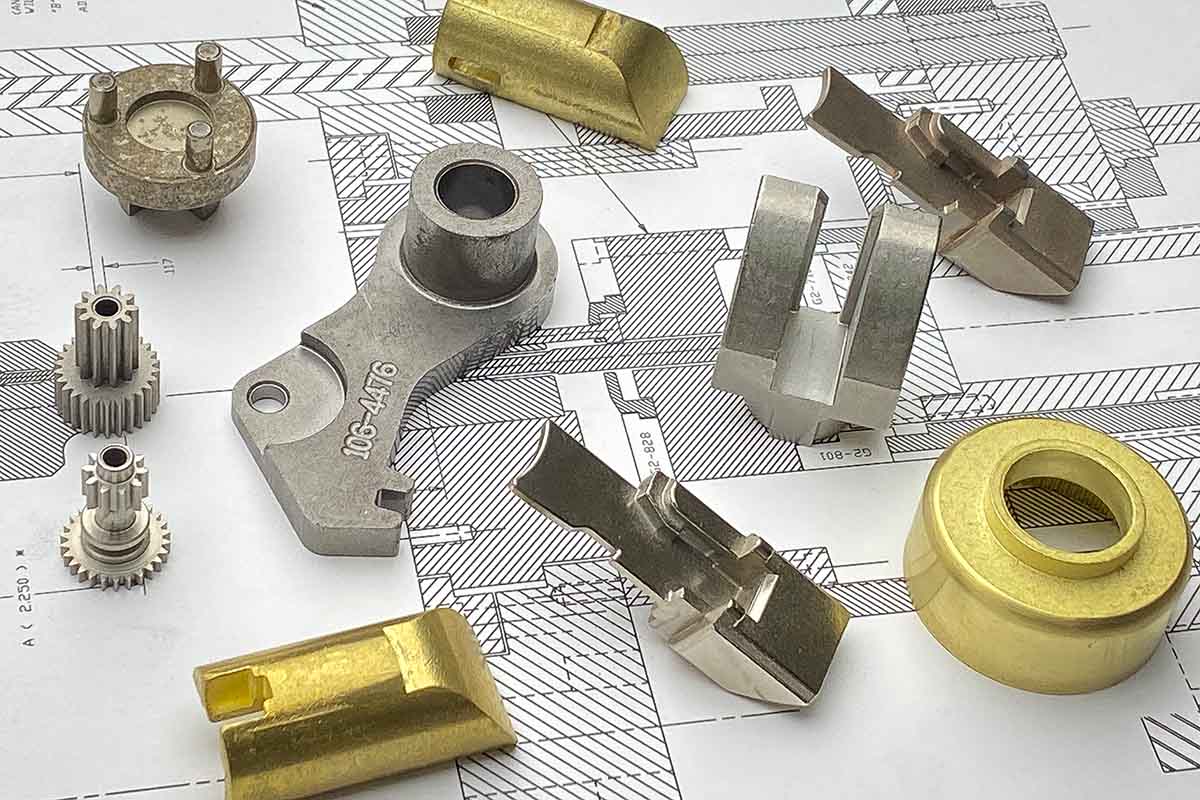

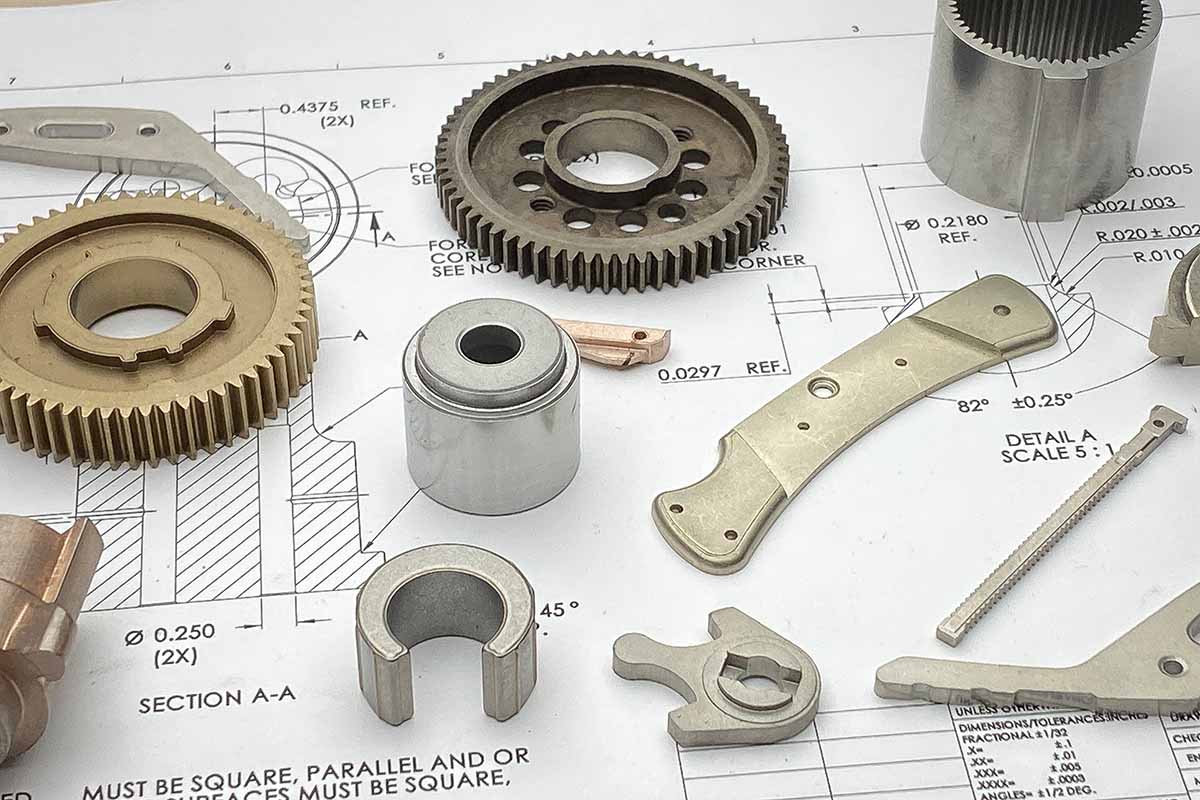

Powder metal Coupling are made through a process named as Powder metal process which is most widely used to manufacture power transmission devices. Automobile industry is predominant market for Press/Sinter structural Powder Metallurgy parts. On average across all global regions, around 80% of all powdered metal parts are made up of Stainless steel for automotive applications.

The process to manufacture coupling begins with the metal powders and those metal powders may be a single metal or it may be an alloy that is combined with lubricant. The mixture is put into a compaction press. The shape is compact into green part that will have a pretty low strength. The desired properties are not present in green part. To get the desired properties the green part will go through the copper sintering process.

Components are copper infiltrated for a number of reasons. Some basic desired results are improvements to tensile strength, hardness, impact properties, and ductility. Copper-infiltrated components will also have an excellent density.

The characteristics of metallic couplings are listed as:

- They are torsionally stiffer.

- With a higher power density, they offer best torque to diameter ratio.

- They have an excellent torque capacity and chemical resistance.

- Offer wide range of temperature which is usually limited by sea oil.

- Couplings are available in various kinds of materials with zero backlash.

- No projecting part is required for alignment.

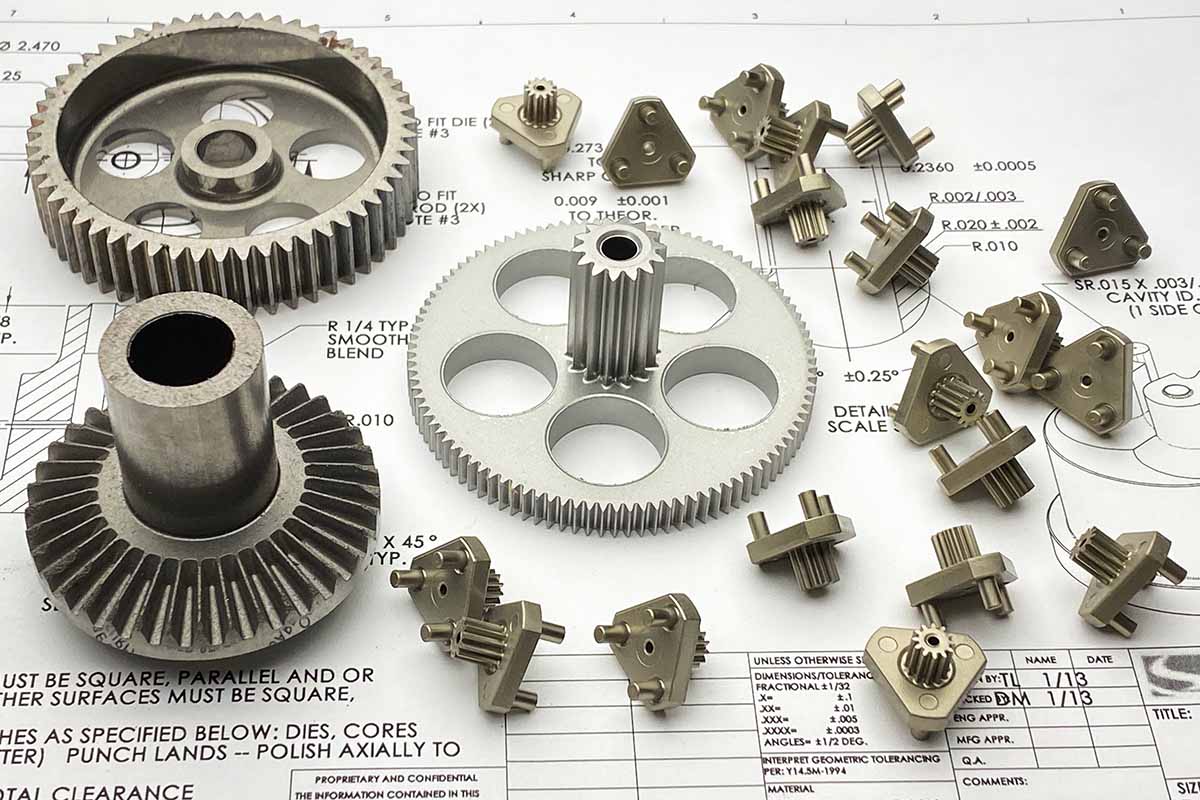

There are various kinds of selection parameters which take into account while selecting an appropriate coupling like; power transmission, torque capacity, maximum angular or parallel misalignment etc. In high output (kW) and high torque devices, where vibration is involved, misalignment and shock loads occur Grid Couplings are an excellent choice.

The unique and concise design of the grid and hub teeth allows these couplings to provide movement and stresses from all three planes, which can overcome vibration levels upto 30%.

Coupling maintenance is important and it requires a regularly planned inspection of each coupling. It includes visual inspections, checking for signs of wear or fatigue and cleaning of couplings regularly. Improper installation can also leads to damage of coupling so, it should take into account.