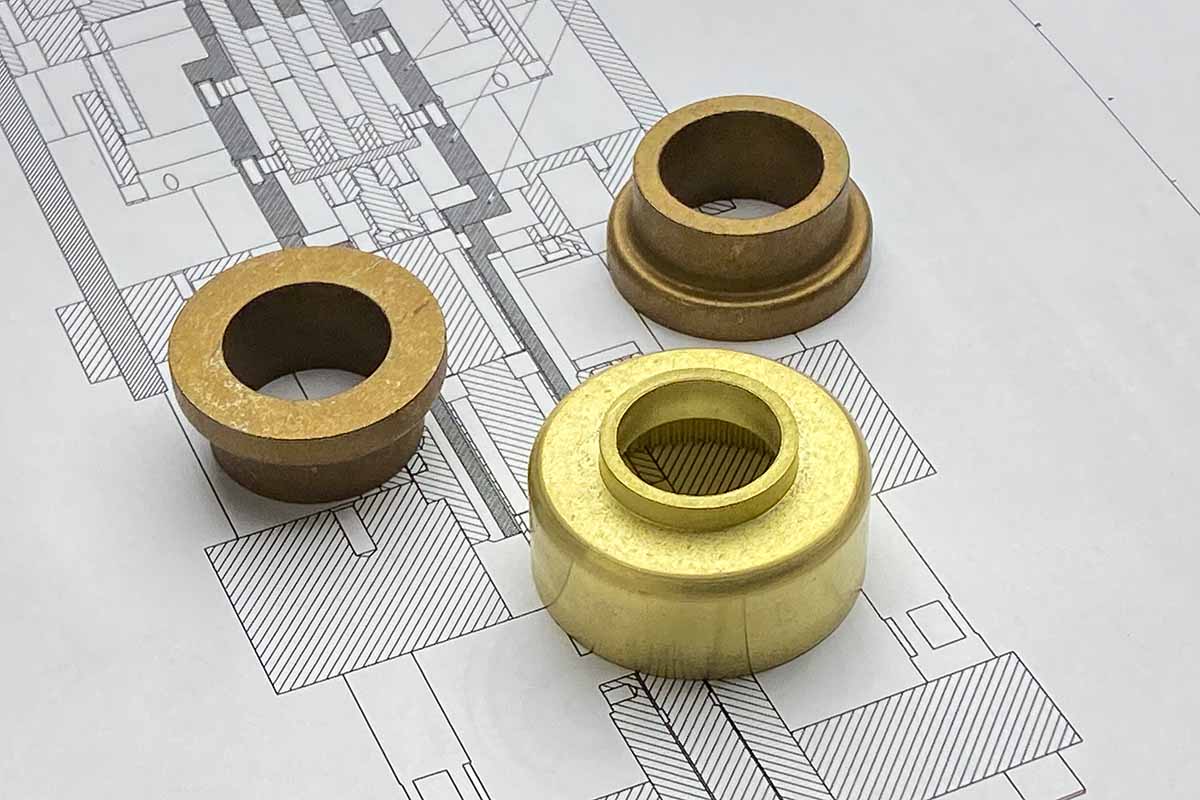

Material of Sinter Bearings

The most popular material for sinter bearings is bronze – 90% Cu (Copper) and 10% Sn (Tin) alloy. follow the link about sintered bronze bearings. Other used materials: stainless steel, copper steel, iron, etc.

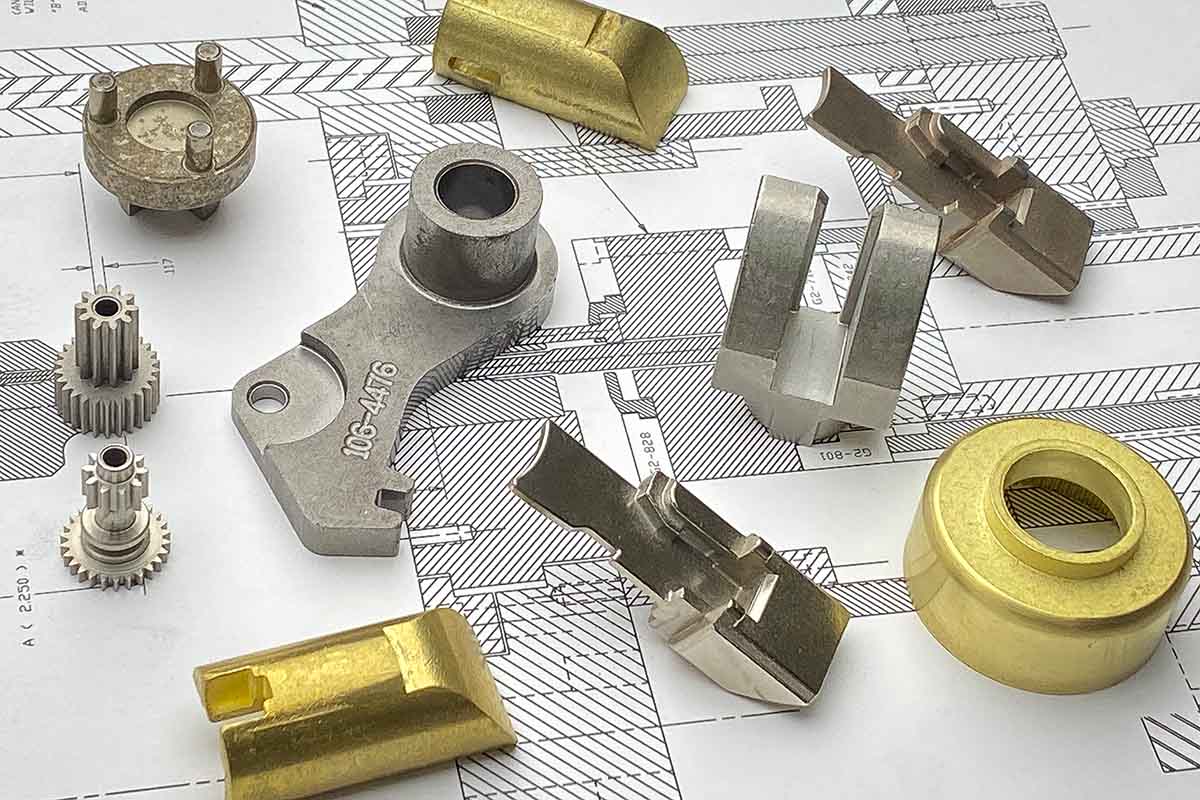

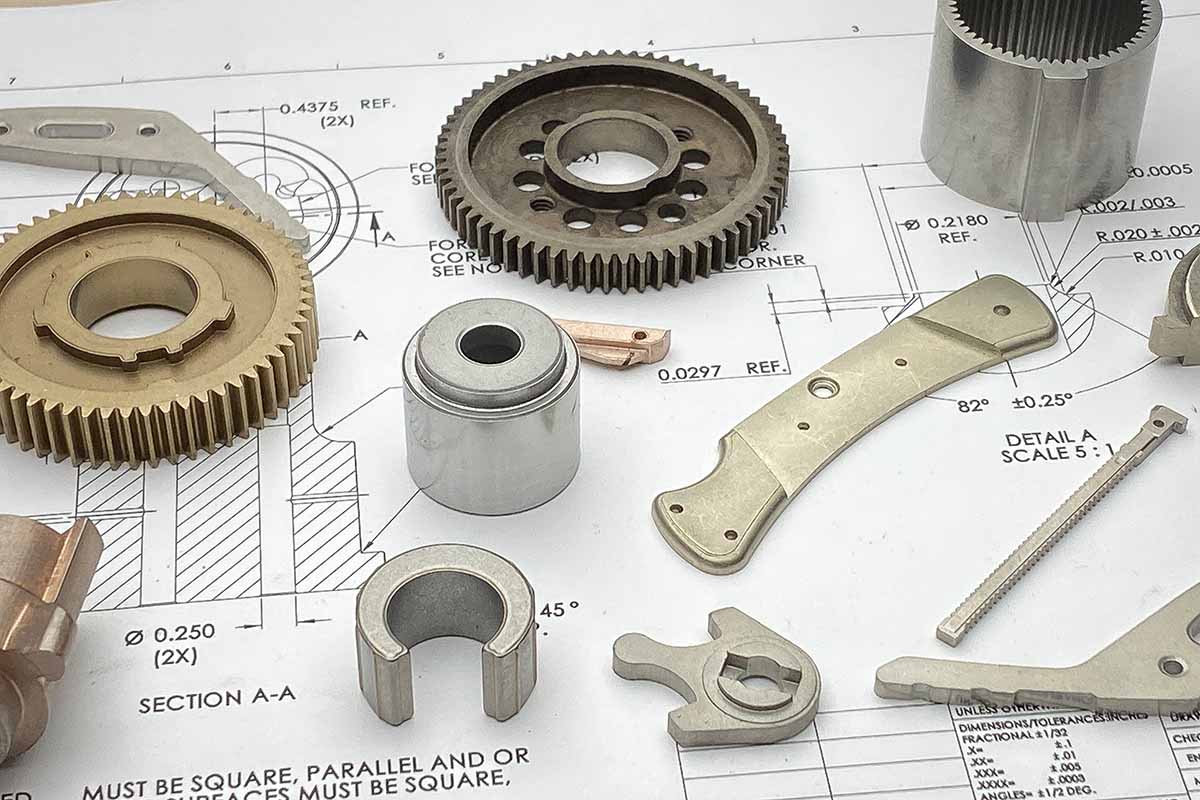

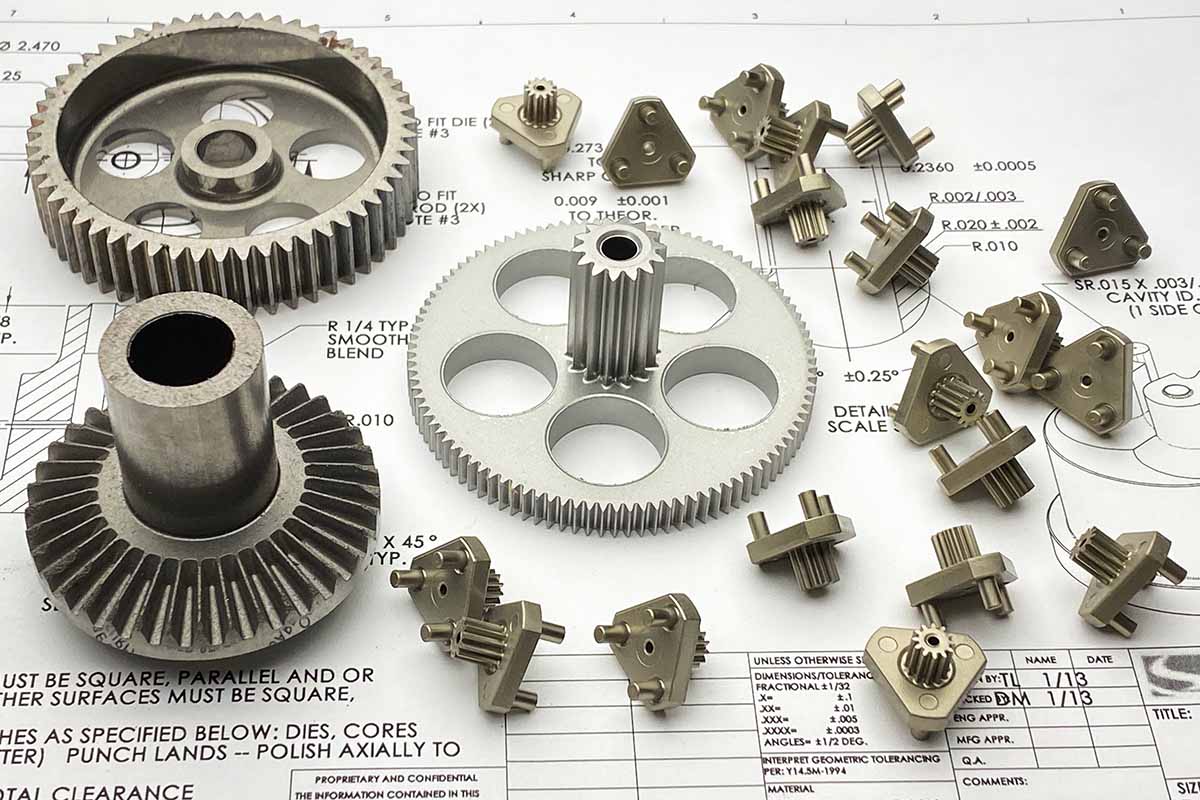

Manufacturing

You can find machined bearings however, the most popular method of manufacturing is powdered metallurgy and there is a number of reasons for that:

- Cost efficiency, powder metal allow making sinter bushings net shape with zero machining,

- Price per piece can be 2-10 times cheaper to make sinter bushings using powdered metallurgy.

Self lubrication

the advantage of powder metallurgy that you can control porosity of sintered bearings to 20-25% of volume, after sintering bearings follow next process: oil impregnation. during that process, oil fill pores to allow self lubrication of sintered bearings