Do You Have A Construction Project We Can Help With?

ASCO History

ASCO Sintering Company was formed by Robert St. Clair in 1946 as a distribution company for self-lubricating bearings produced by companies such as Keystone Carbon and Boundbrook. The company later developed a niche, by machining and turning standard bearings to

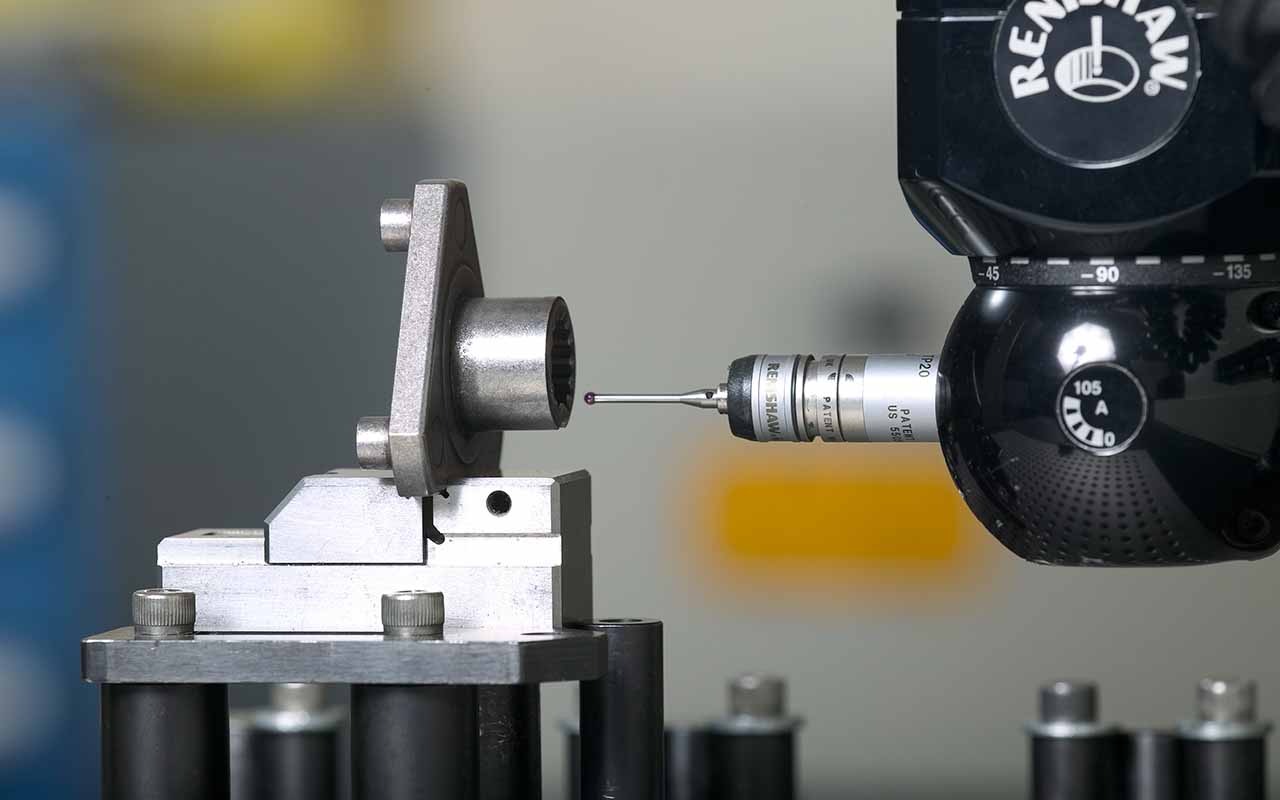

Advantages of powder metallurgy

Economic mass production of precision parts Powder metallurgy is a well-established mass production method for structural parts, bearings, filters, tool parts, magnets, friction materials, contact elements and components from refractory metals. Its basic steps are powder· production, mixing, molding into

HI-IMPAC Case history

Hi-Impac, a P/M (Powdered Metal) material and process that produces powder metal parts with significantly better properties than those obtained with conventional high strength P/M. The part shown above was originally made from P/M infiltrated steel (FX- 2008-n When tensile

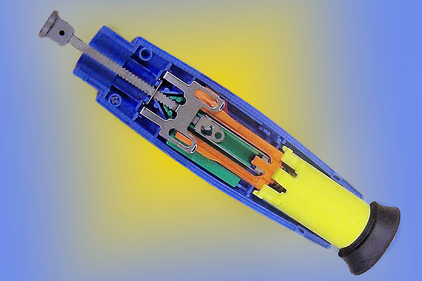

Hydraulic Quick Coupler

Diverse range of industries are using Hydraulic quick couplings, including construction, agriculture, food and chemical processing, forestry, etc. These hydraulic couplings are specially designed for high-pressure hydraulic operations to reduce pressure drop across the hydraulic connection. It provides the most

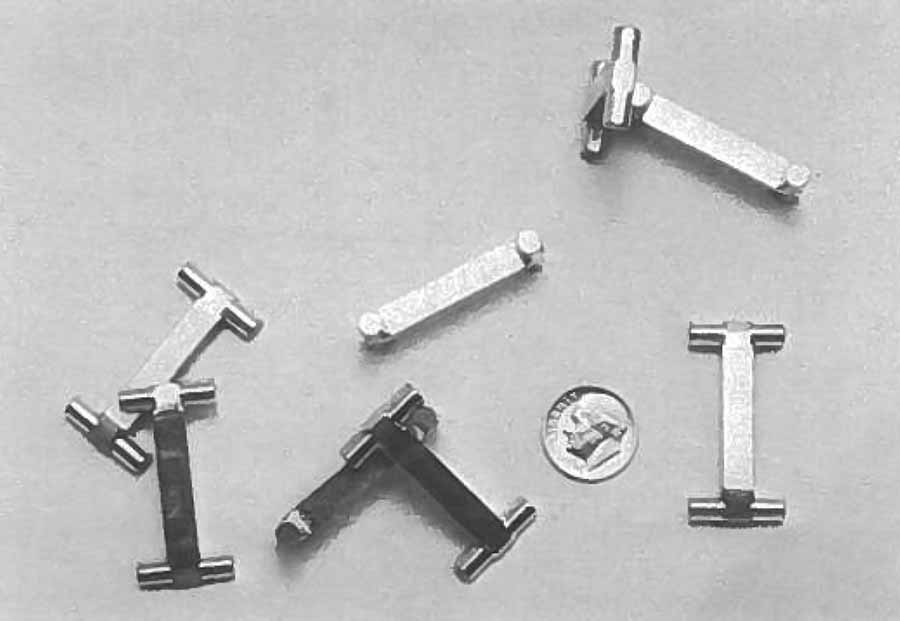

Osteoporosis pen ratchet

ASCO Sintering Co. manufactures stainless steel ratchets. The osteoporosis pen ratchet serves as an indexing component in an at home prescription drug delivery system. Each tooth represents the daily dose of a prescription osteoporosis medication. With density of 6.5 gr/cc

40mm high & low velocity fuse rotors

ASCO Sintering Company, Commerce, CA has supplied a selection of different fuse rotor designs, for the US Army M549, M549A1, and M550, 40mm and 50 mm high and low velocity rounds, for over 30 years. These highly detailed precision components