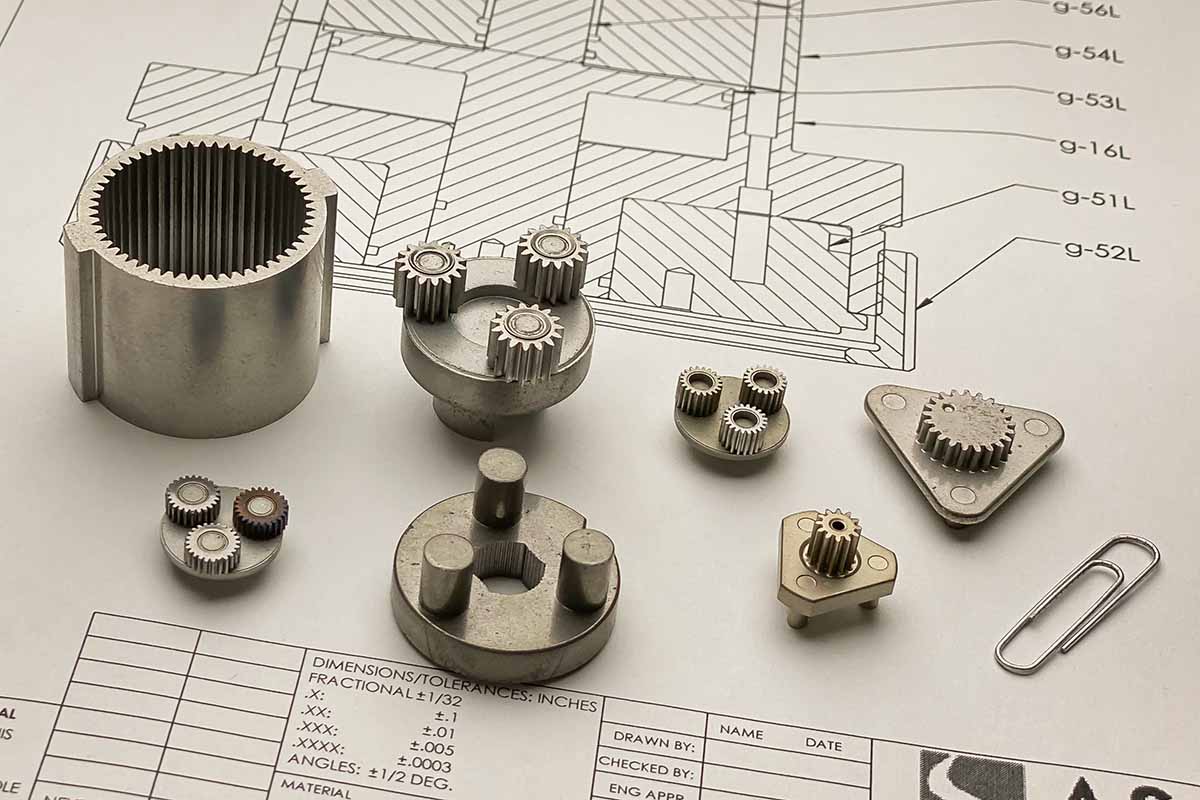

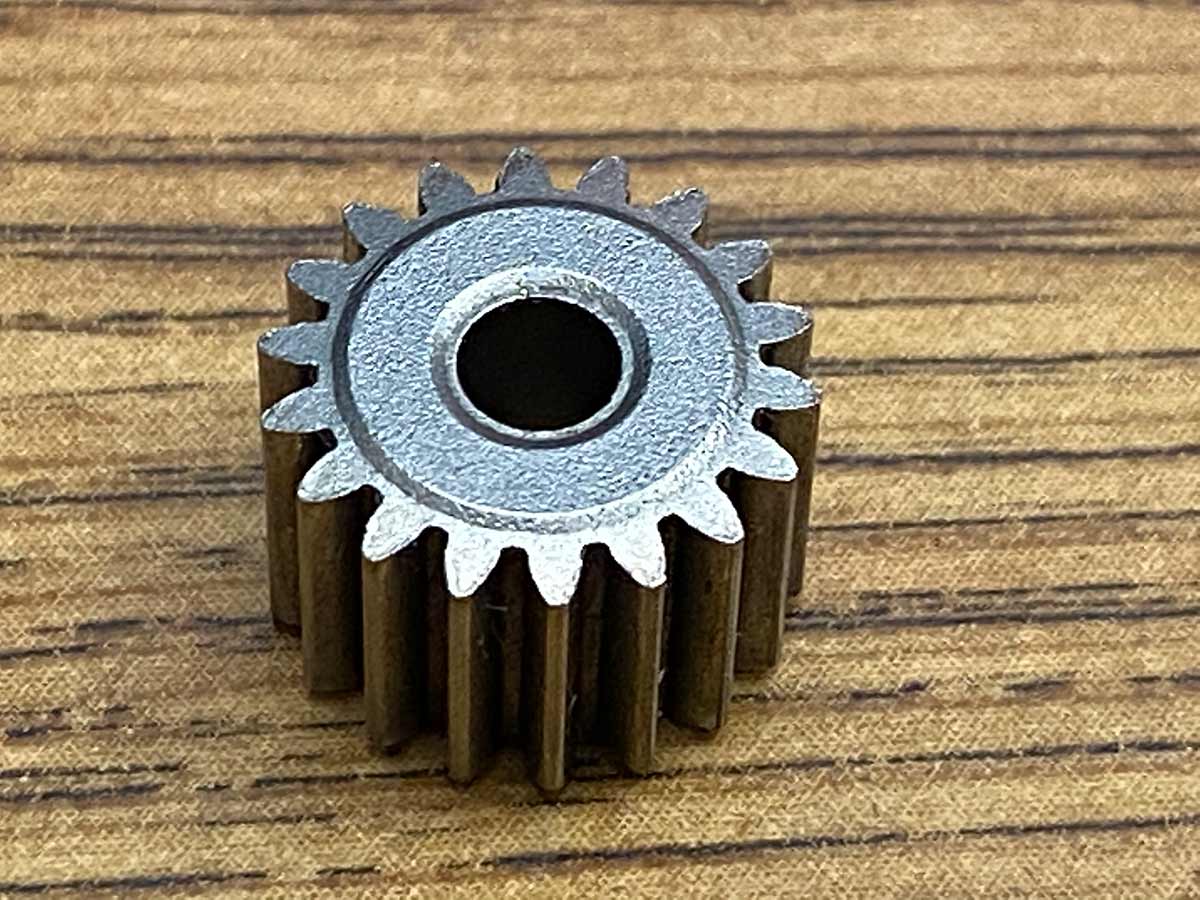

Planetary Gear Systems

The planetary gear is a type of gearing system to lower the speed of a rotating shaft. A planetary gear system consists of three main components: a sun gear, several planet gears, and a ring gear. The position of the sun gear is in the middle of the gearing system. The planet gears are distributed